Guerreiro Romani has been a freelance industrial engineer and designer since 1986. The primary focus of his company is to design and provide external support to pump manufacturers such as sea water self-priming pumps, waste water submersible pumps, and vacuum-assisted wellpoint pumps. The company’s current customers are pump and industrial equipment factories with a turnover of up to €10 million. Guerreiro Romani has been a SimScale customer since November 2018. He believes that simulation is critical to small companies and factories to make reasonable predictions of product performance. As a freelance designer, he uses simulation for feasibility studies and to inform prototype testing.

Guerreiro Romani uses SimScale for a variety of pump simulations, ranging from cooling pumps to submersible pumps. The objectives of each project are different and in this case study, we will look at two of them. Guerreiro Romani first adopted SimScale in November 2018 while looking for a cloud-native computational fluid dynamics (CFD) software to evaluate the energy wasted due to back leakage into a volute end of a self-priming pump. Moving fully to the cloud was a big improvement over legacy CFD tools. There was no longer any need for specialist hardware, high capital costs, data storage, tricky license keys, etc. SimScale is accessed on a web browser with many of the traditional CFD workflow operations now automated, such as meshing. With the help of SimScale’s expert support team, Guerreiro quickly learned to navigate his way through the platform and within a couple of weeks, was able to independently perform end-to-end CFD analysis of pumps in SimScale.

I’ve run simulations of almost every type of pump I've designed over the past 40 years. The insight obtained from CFD simulations in SimScale is like looking inside a transparent machine using a laser doppler velocimeter. It is priceless!

Guerreiro Romani

Industrial Engineer and Designer

Two different projects undertaken by Guerreiro are presented here. The first is a self-priming centrifugal pump (P246) and the second is a custom gear-driven pump (P162). P246 was one of the very first projects that Guerreiro undertook using SimScale. This was the first time Guerreiro used simulation at such an early stage of development; the usual practice was to rely on costly physical prototyping. P162 came three years later and by then, Guerreiro had become a SimScale power user, encouraged by the immense savings in prototyping time and cost negated by using SimScale.

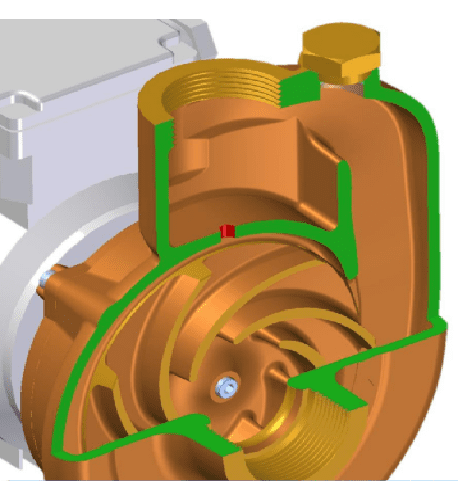

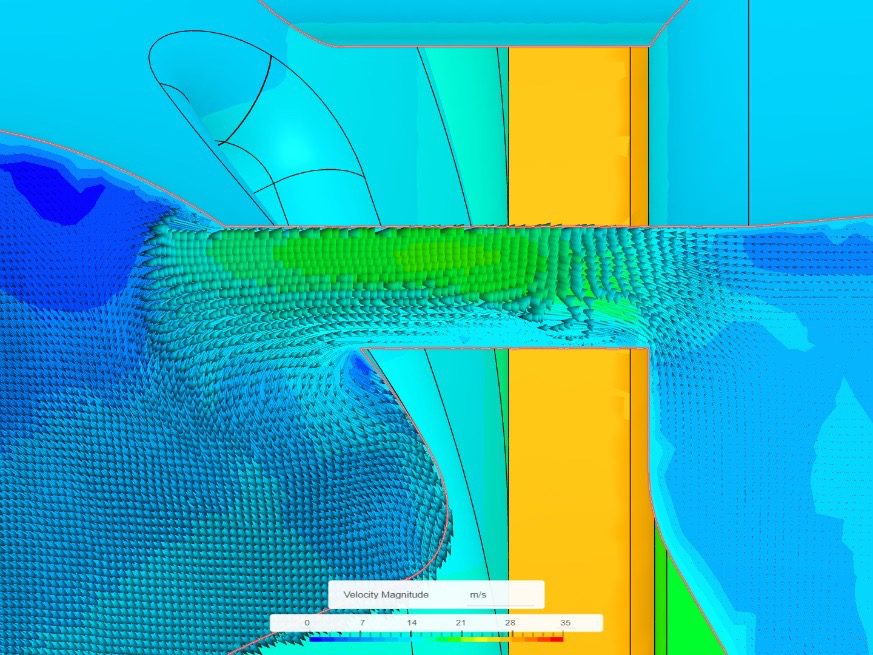

In this project, Guerreiro evaluated the efficiency drop of a self-priming centrifugal pump with a hole in the volute. A small hole in the pump volute is standard practice to evacuate unwanted air from the system during self-priming, with an accepted downside of reduced efficiency. Additionally, Guerreiro was concerned about energy losses due to back leakage of flow into the volute at the end of the self-priming phase. Using SimScale, Guerreiro was able to simulate the fluid flow that passes through the priming hole and also assess its associated energy losses.

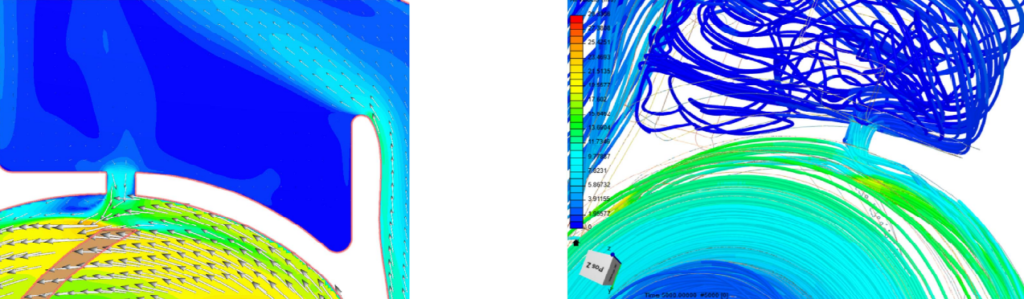

SimScale’s incompressible analysis type was used for this simulation. The incompressible solver is adequate where density variations in the flow are negligible, such as when velocity and temperature gradients are relatively small. A steady state simulation setup was used, with the k-omega turbulence model combined with an MRF (rotating zones) for describing the rotation of the impeller. The Hex dominant mesh was used to quickly generate a first-level mesh, which was then refined for mesh-independent results.

A total of three operating points were run for P246 to evaluate pump performance. Using the inbuilt and easy-to-use post-processing module, he was able to visualize the extent of backflow through the volute and he also found that the backflow had negligible impact on pump performance. This helped him conclude that the pump could be operated without any design modifications and that a small electric pump can be deployed in the self-priming mode with negligible increase in energy consumption. Guerreiro continued the study to evaluate the transient flow pattern through the pump, to arrive at an optimal diameter and location of the priming hole.

Guerreiro extracted velocity and pressure distributions in and around the pump using SimScale. Previously, for high-accuracy in-situ measurements, he should have used expensive techniques like Laser Doppler Velocimetry. Seeing the simulated results from SimScale matched experimental results, creating virtual test and measurement scenarios was seen as critical to providing a high-level service to his clients at a reduced cost.

In this case, SimScale made it possible to carry out pre-validation directly on a digital twin, faster and more economically than on a physical prototype.

Guerreiro Romani

Industrial Engineer and Designer

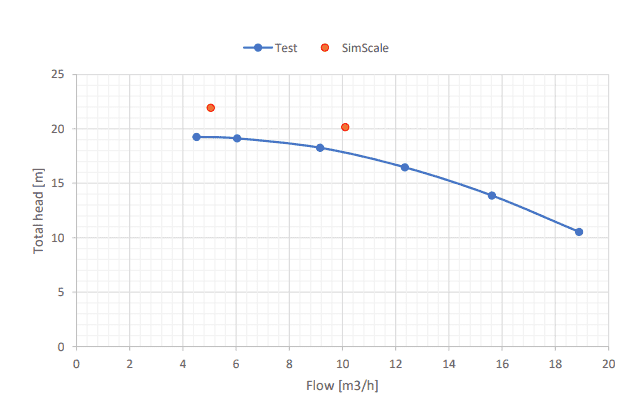

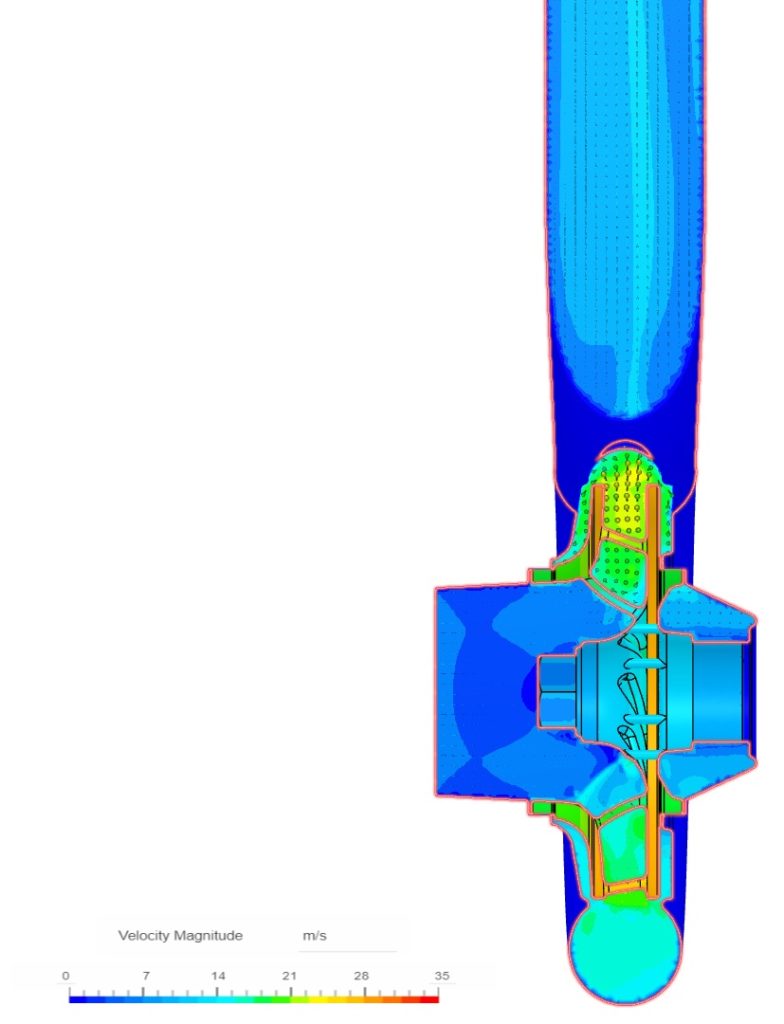

Project 262 (P262) is an ongoing project with Guerreiro and the objective is to evaluate the performance of custom gear-driven pumps, including the effects of cavitation. From the designer’s perspective, the goal is to reduce the gap between expected and achieved performance. Traditionally, one-dimensional empirical data obtained from experiments of a similar model are used to evaluate the performance of a new pump design. Taking a geometrically similar turbomachine as a reference, however, does not always yield the most accurate results and also restricts the design space that can be explored. In these situations simulation is an essential tool for product development and testing.

Guerreiro used the OpenFOAM-based incompressible analysis type for his initial tests. The detailed analysis was carried out in the new Subsonic solver, a turbomachinery-specific solver with a full cavitation model for pump NPSH characterization. The physics-based automatic mesher in Subsonic allows hassle-free mesh generation and the binary tree algorithm ensures that small gaps and critical features of the geometry are correctly captured. Overall, 21 steady-state simulations were run in parallel to obtain the characteristic curve of the pump, including pressure head, shaft power, and efficiency as a function of flow rate. The entire pump curve was obtained in 2 hours using just 30 core hours per operating point.

Guerreiro wanted to validate the 1D empirical calculations using mathematical models and also had access to test bench data for the P262 model. The simulation results for the P262 centrifugal pump showed a good match with experimental data for pressure head and efficiency over a range of flow rates. Guerreiro intends to continue this project to include cavitation analysis as well as study how he can extend the operating range of the pump by incorporating 4 or 5-bladed impellers. Using a simulation-driven approach in SimScale, Guerreiro was able to save experimentation costs, and the analysis turnaround time was reduced from two weeks to two hours, helping him carry out more studies to reliably predict the performance of modified pump designs.

Overall, by using simulation, Guerreiro saved on average €10k in design and prototyping costs on specific projects. Design turnaround times have been reduced from months (including labor, test bed availability, and prototype manufacturing) to several days by obviating the need for physical prototyping and testing on each project. SimScale has been especially useful for evaluating newer designs in projects that did not have geometrically similar and existing pumps to compare performance parameters to, or base a modified design on. Guerreiro is also interested in using the upcoming blade-to-blade visualization to analyze the near-blade flow for two of his current projects.

A project to put a machine into production is a complex job. Many tasks must be completed to move from the first idea to the prototype, typically only the dimensioning phase requires a simulation or a simulation cycle. I was really afraid of thousands of potentially modifiable parameters without knowing their effect on results, but the SimScale staff support was very effective to remove all doubts. A lot of time was spent racking my brain to figure out software commands, however, it paid off with results not otherwise achievable. In this case, SimScale made it easy to assess feasibility, saving both time and money on hardware upgrades, and providing excellent software and great online support. Many thanks to SimScale.

Guerreiro Romani

Industrial Engineer and Design

Sign up for SimScale

and start simulating now