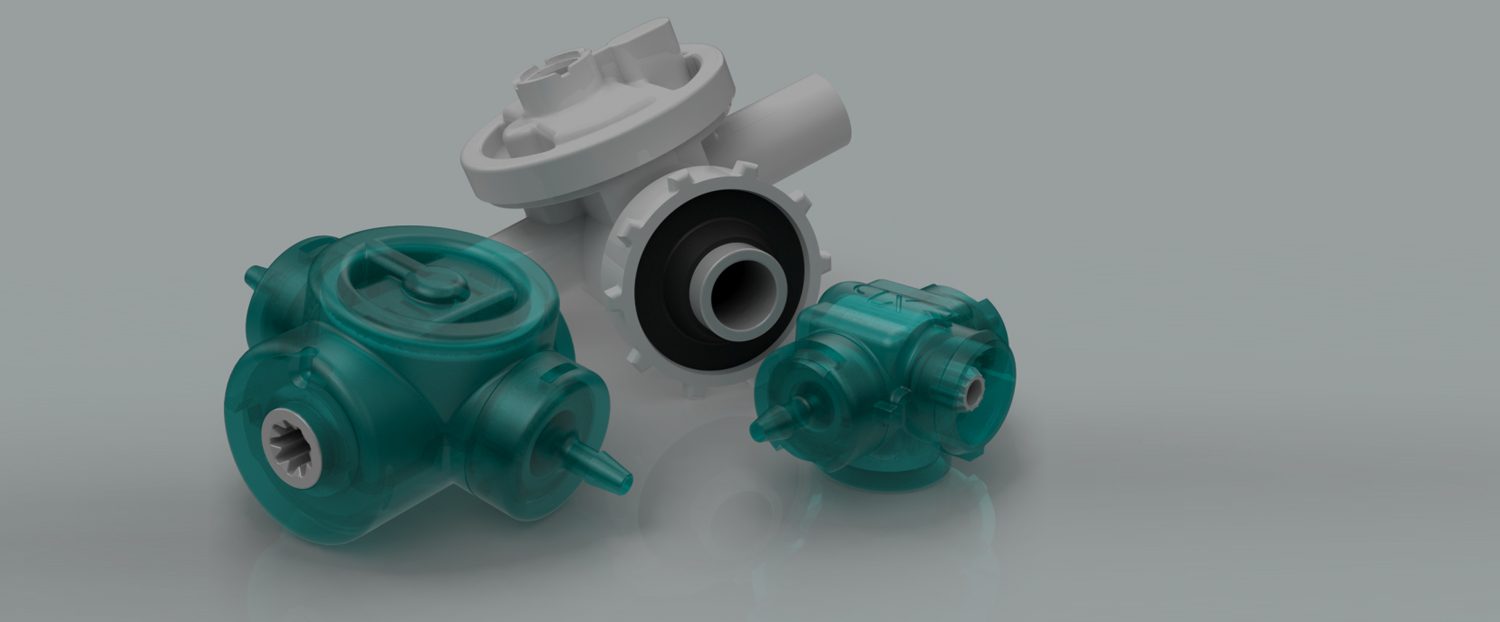

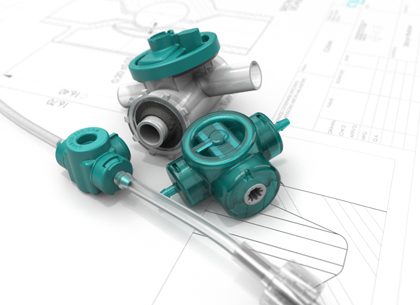

As a leader in disposable pump technology, Quantex designs and develops single-use pumps. Its products evolved from the biomedical market, replacing the old peristaltic pump technology by improving accuracy and ease of drug administration. Recently, Quantex has expanded its product base to other industries, such as food processing.

Moving to new verticals and markets often requires the introduction of new products. Opportunities in the food dispensing business drove the development of the biggest pump so far—the Series 20 model. Of course, simply scaling the existing design and expecting it to work for a different purpose was not a solution. The goal was to modify the concept design such that it would provide the maximum manufacturing cost savings, while allowing for the highest operating flow rates. With Quantex’ pumps being produced in millions of units, each gram of plastic saved during production was very valuable.

Making a new, bigger model posed multiple challenges. Newly designed parts of the pumps included very thin deflective polypropylene membranes, which made producing the membranes with the desired thickness and very small tolerances created significant difficulties for the manufacturer. Expensive iterative modifications to the molds would have had to be applied and the whole production process would have become much longer. Quantex’ engineer Jonathan Ford decided to investigate the deflection of the membrane undergoing pressure load depending on variable plastic thickness. The CAD tool used at Quantex already had structural analysis capabilities, but it did not allow for nonlinear FEA analysis. The extra calculation package was very expensive and this is when Jonathan discovered how cost-effective SimScale is.

At Quantex, the SimScale platform gives us access to powerful tools, in an economic package. The support is outstanding and helps add the most value to our engineering capabilities.

Jonathan Ford

Engineer Quantex

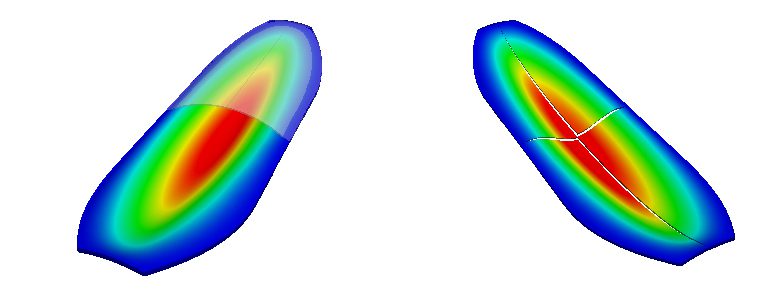

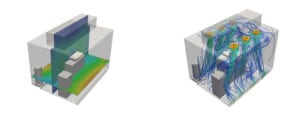

The first step in analyzing the new pump design was to extract the geometry of the membrane from the model. A reference, square membrane was tested at this step. Of course obtaining a good 3D mesh of a geometry that has high aspect ratios is not very easy. The user needs to make sure that the mesh is sufficiently fine to capture the actual behavior of the system while keeping the number of nodes as small as possible to avoid long calculation times.

The square-shaped geometry had already been studied experimentally. The comparison of the final maximum deflection of the simulation and the physical test has shown good agreement. This meant that the coarse mesh could be used to analyze the new design. Jonathan’s experience with the pumps that used square-shaped membranes pointed out the difficulties with precision manufacturing of the edges. With an increased size of the pump, the problem would be even bigger. A new shape was proposed, where the edges would be rounded, and the whole membrane would look more like an oval. The main variable parameter now was the actual thickness of the membrane. Jonathan wanted to know what would be the deflection difference when he increased the thickness of the part by 50%.

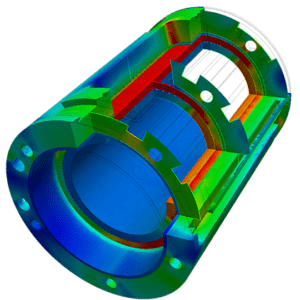

Having the square membrane case done earlier, creating proper meshes for both new versions of the design was easy. The selected calculation type was nonlinear advanced structural analysis. Thanks to the customization features of SimScale, Jonathan was able to utilize the polypropylene as the material used in the actual product. To deform the membrane, a pressure load was applied to its top surface. At first, the pressure was distributed uniformly across the surface. The selection of such condition on the platform was quick and straightforward. At the same time, it was a bit far from reality, since reference cases have shown that the pressure force is proportional to the deflection of the membrane, decreasing with deflection. Fortunately, SimScale provided the possibility of non-uniform force distribution.

Jonathan came up with a smart functional definition of the pressure load, which better mimicked reality. The final element of the simulation setup was the choice of numerical schemes. Jonathan favored fast calculation, so relative convergence criteria were selected and the default tolerances were loosened up. The geometry was expected to undergo big deformations as the force was ramped up. With strict convergence tolerances, it would create significant trouble with getting a solution in this transition state. The tolerance of the calculation at maximum deflection was much tighter than defined by the convergence criteria which added confidence to the result.

Each of the simulation runs took around 25 minutes. Once completed, the data was downloaded and analyzed using ParaView. The results were very encouraging. The decrease of displacement of the membrane when increasing its thickness by 50% was definitely in an acceptable range. Knowing that the manufacturing defects would generally never exceed the tested maximum thickness, the production tolerance limits were increased by 50%. This gave a larger processing window and increased confidence level that the pump was production capable. Furthermore, several expected expensive iterative modifications to the molds and the production process were avoided.

Finally, the calculated deformed shape of the membrane was overlaid on the pump’s geometry. It appeared that additional improvements to the pumping area were now possible, which would result in an increase of the devices’ performance. Overall, the CAE approach to the design optimization allowed Quantex to improve its product, safely investigate a new design, and save money and time. With the new pump being manufactured, further studies are planned for the optimization and customization of the product.

Knowing that the manufacturing defects would generally never exceed the tested maximum thickness, the production tolerance limits were increased by 50%.

Sign up for SimScale

and start simulating now