Axens provides a complete range of solutions for the conversion of oil and biomass to cleaner fuels, the production and purification of major petrochemical intermediates as well as treatment and conversion options for natural gas. With clients from energy and chemical markets from around the world, Axens offers technologies, equipment, furnaces, modular units, catalysts, adsorbents, and related services.

Initially, the Axens team had little experience with cloud-native simulation technology, so they were concerned about the business impact and the overall turnaround time for their CFD projects. Their biggest bottleneck was CAD import and CAD model cleanup as well as performing CFD simulations that usually took them months which made it very hard for Axens to cut down on development cost and production time.

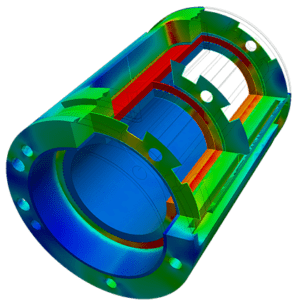

Prior to using SimScale, the team relied heavily on external resources to make use of CFD in the early stages of their product development process taking them months to get proper results from their optimization studies. With SimScale, this could be done in literally days. By bringing CFD in-house, Axens was able to increase efficiency in their design process. The team has been using SimScale as a solution for simulating chemical reactors, piping layouts, and more.

Axens investigated two different use cases using SimScale’s cloud-native CFD technology, which enabled Jean-François Le Coz, Technology Development Manager, and his team in the Technology Development & Innovation Division to solve complex fluid physics and make quick design decisions.

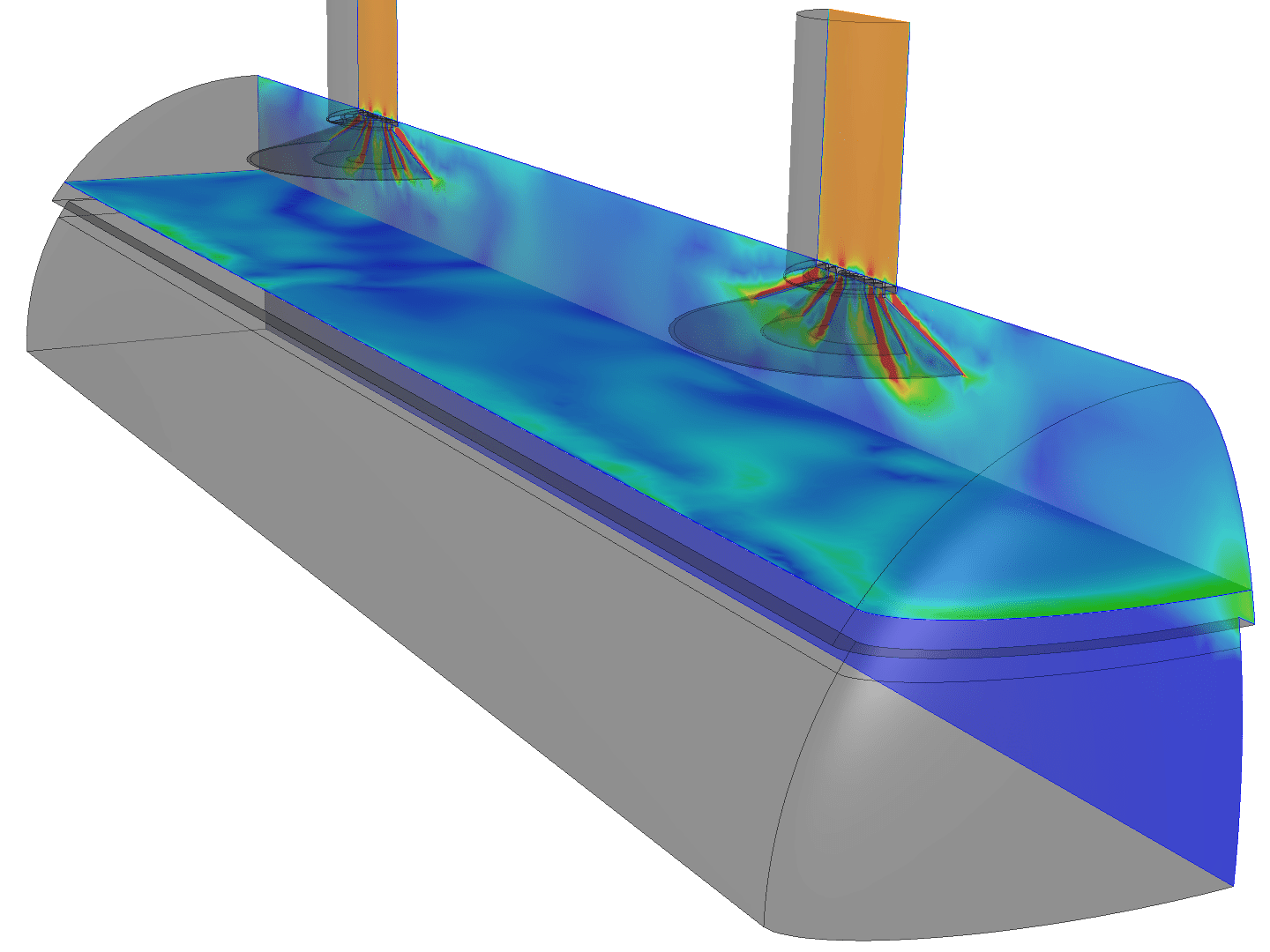

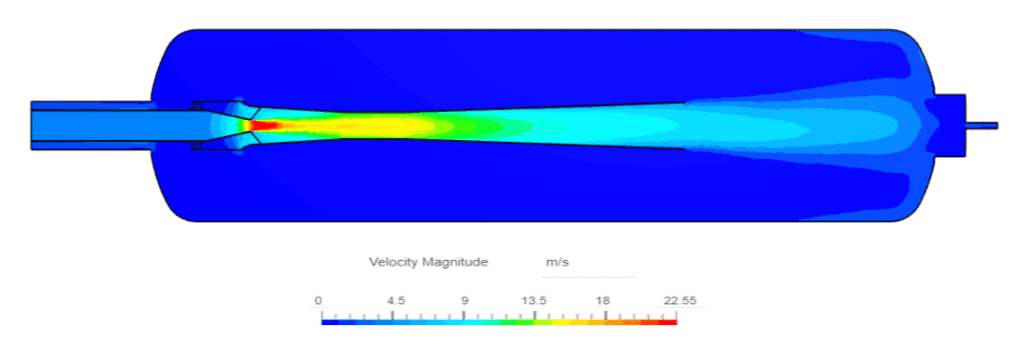

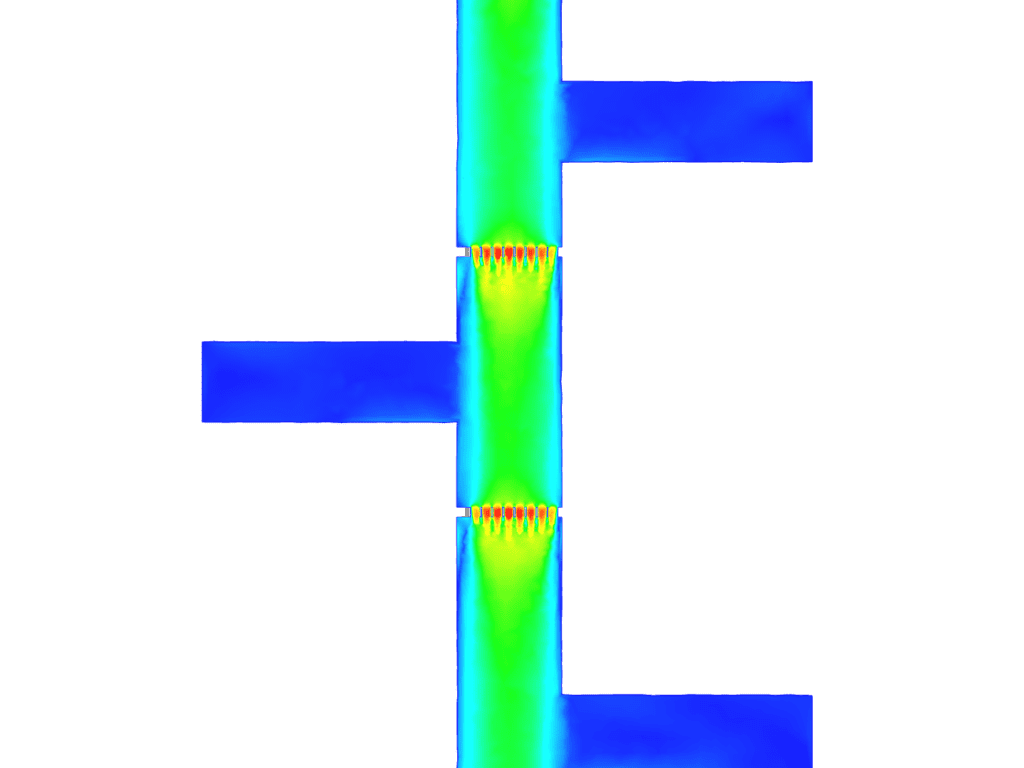

They ran more than 50 simulations in four months and were able to improve four types of existing equipment. We present hereafter Axens’ CFD studies for an eductor and flow conditioner designs that were both simulated using an incompressible steady state approach and a k-omega SST turbulence model.

Axens ran more than 50 simulations in four months and were able to improve three types of existing equipment, not only leading to improved mixing performance in different tank designs but also less pressure drop. For example, an eductor design was optimized to require 20% less energy consumption. With a pump of 1200 cubic meters per hour capacity, the new eductor design requires 7 kW less energy than the previous design. With just this design study alone, Axens not only saved money on the cost of outsourcing the CFD analysis but also saved an additional 20,000 EUR in overall development costs in just two weeks by simply using SimScale’s CFD module.

In addition to optimizing their reactor mixing design for improved performance, Axens used SimScale to quickly and accurately evaluate different design parameters and output quantities, including the:

In their second study, Axens used simulation to design new equipment and further enhanced their knowledge of simulating the bed adsorption processes. A flow conditioner optimization reduced the variations in pressure drop between designs, from over 50% discrepancy down to only 10%. This allows the unit to achieve more uniform, reliable, and repeatable pressure drop. This results in more homogeneous flow behavior along the flow conditioner, ensuring that the correct flow rate is achieved inside the catalytic absorption bed. Axens was able to increase the capacity of the unit by around 10%, leading to an improved product offering with better margins for their client. For this flow conditioner case alone, Axens saved around 7,000 EUR in external costs. Important note: the flow conditioner standards as described in ISO-5167 did not lead to satisfactory behavior!

Be confident in SimScale! The solution is easy to learn and taking advantage of the live chat support is a must, with very short answering delay and valuable input!

Jean-François Le Coz

Technology Development Manager - Technology Development & Innovation Division at Axens

The Axens team found SimScale to be intuitive and easy to work with, especially with SimScale’s support team readily available. The integration of cloud-native CFD with their existing workflow has enabled them to seamlessly incorporate more simulations into their design process and leverage the full power of cloud computing. SimScale’s library of tailor-made customer project templates gave Axens the ability to efficiently learn from simulations and easily transfer knowledge from one project to another. Plus with their team able to collaborate remotely, Axens was able to set up, simulate, and analyze the results of their performance assessments in a much shorter turnaround time. In fact, SimScale enabled them to reduce their development time down to only two months, compared to a 6-12 month runway with their previous technology stack. Net result is more and faster innovation with considerable cost savings.

Jean-François emphasized that Axens will integrate more CFD simulations into other product development processes in the future. As an efficient solution for engineering simulation, remote collaboration, and, ultimately, product design optimization SimScale helps keep Axens at the forefront of sustainability and cleaner fuels.

Sign up for SimScale

and start simulating now