SimScale enables designers and engineers to optimize product design and reduce prototyping costs and time to market by simulating both the thermal and structural aspects of electronic designs at any stage directly from their web browser.

SimScale is a cloud-native simulation software that enables engineers to test, validate, and optimize designs using a standard web browser. Engineers can perform cooling, heat, and fluid flow analysis of electronic devices, PCBs, electronics systems, and enclosures along with structural and mechanical assessment using a single CAD model, all in one simulation platform.

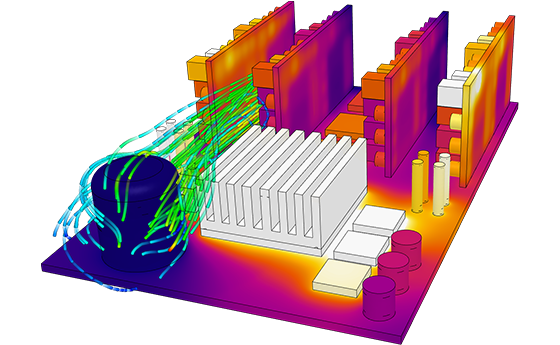

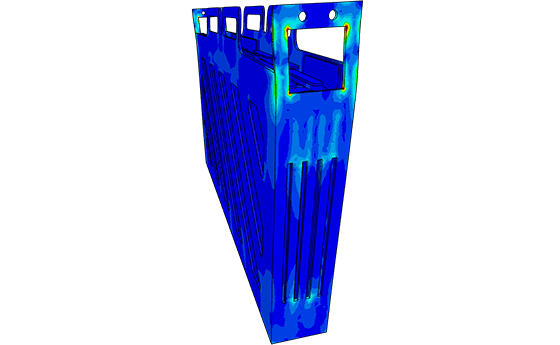

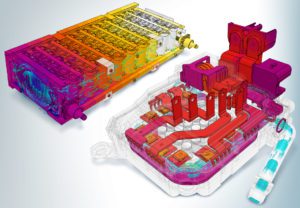

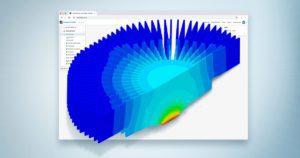

Many materials and products have temperature-dependent characteristics making the analysis of heat and thermal management of structures and fluids crucial for product development. The SimScale cloud-native simulation software platform allows engineers to predict the airflow, temperature distribution, and heat transfer of many types of electronic devices, from LED enclosures to data center cooling strategies. SimScales’ industry-leading and powerful solvers provide robust CAD interoperability meaning that more time is spent on design analysis through simulation rather than on CAD cleanup. Furthermore, the resultant time and cost savings from simulating early and often, allows engineers to explore more of their ideas, using the parametric capabilities in SimScale and integrations with third-party CAD and analysis packages.

Industry Products and Product Categories

SimScale provides high-fidelity thermal analysis simulation tools that are both technically and economically accessible for designers and engineers, at any scale, in the cloud. Electronics product categories that can benefit from SimScale’s simulation capabilities:

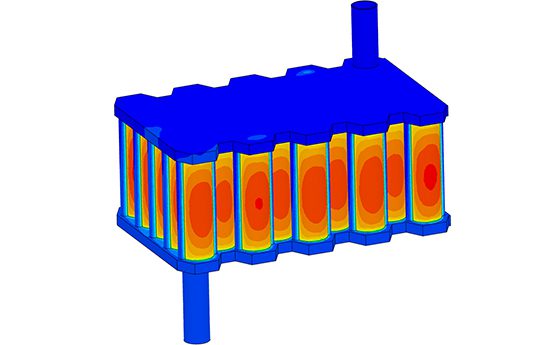

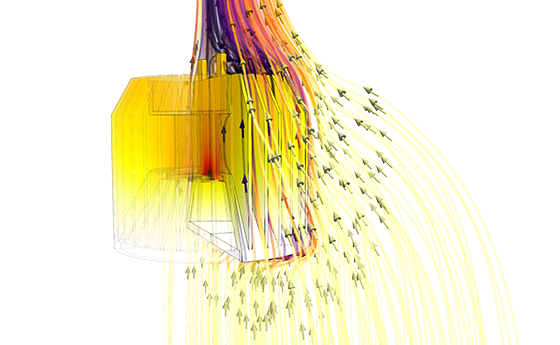

SimScale solves all three heat-transfer mechanisms from first principles. Conduction refers to a heat transfer between solids that are in direct contact with each other and depends on the heat conductivity of the materials. The SimScale thermal simulation software offers a module for various types of applications where heat and energy are significant study parameters. Engineers can simulate conduction between different materials and can also model temperature-dependent conductivity. Convection (also referred to as convective heat transfer) is the transfer of heat between two areas or regions, through the movement of fluids. Applicable to liquids and gasses, it occurs when fluids absorb or lose heat and change density, leading to convection currents, and is available through the convective heat transfer analysis type. Radiative heat transfer, or radiation, is the transfer of heat through electromagnetic waves between substances (solids and fluids). SimScale can model surface to ambient and surface to surface radiation by using emissivity and other radiation parameters.

An electronic enclosure, for example, will be subject to all three modes of heat transfer. In one platform, engineers can simulate conduction, convection, and radiation and optimize the device based on a comprehensive treatment of the underlying physics.

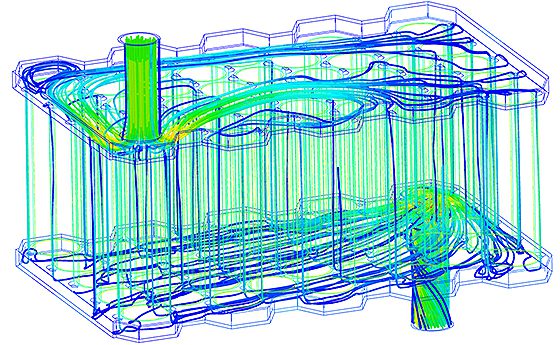

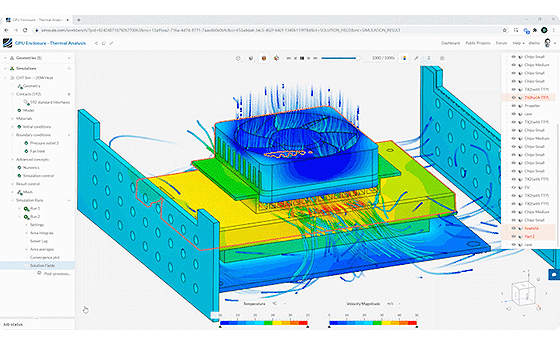

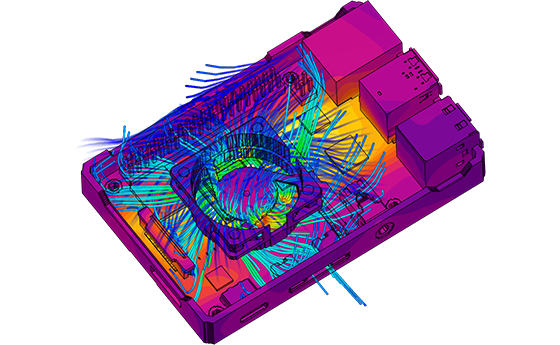

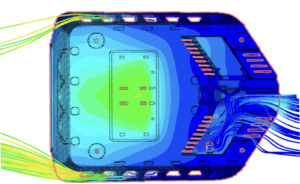

SimScale’s CFD software can analyze a range of problems related to laminar and turbulent flows, incompressible and compressible fluids, multiphase flows, and much more. In thermal management, engineers want to evaluate the flow of air and liquids through components and devices and evaluate variables such as fluid temperature, pressure drop, and flow rate. With SimScale’s many analysis types including Subsonic, engineers can set up parametric studies to answer critical flow-related questions an order of magnitude faster than traditional approaches.

The heat-transfer physics and CFD capabilities in SimScale enable engineers to test multiple cooling strategies including natural convection, forced (fan cooling), and liquid cooling strategies. Boundary conditions for each strategy are easy to set up and run using the intuitive interface in SimScale, as are material selection and assignment. A database of materials in SimScale gives engineers predefined materials that are common in electronics including coolants (fluids), heat sinks, thin layers, and enclosure materials. New features include the ability to upload fan/pump performance curves from the manufacturer and parametric simulation setup workflows that can automate scenario analyses.

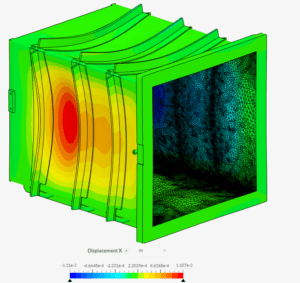

The thermal analysis software takes into account the energy balance of the system that involves calculating the thermal influences on structural load states at each time step, meaning the effects of thermal loads on solids can be quantified. The thermal and structural fields are solved sequentially, in an iterative process, where the results of each thermal step serve as inputs for the corresponding structural step. For many industrial applications, simulating the stress response to thermal loads and understanding failure is essential when developing products that are subjected to temperature-dependent stresses and performance.

The FEA module in SimScale allows engineers to perform different types of structural analysis including static, dynamic, and nonlinear. Vibration or modal analysis can help determine the eigenfrequencies (eigenvalues) and eigenmodes (mode shapes) of a structure due to vibration. The results are important parameters to understand and model structures that are subject to dynamic loading conditions. Additionally, a harmonic analysis can show the peak response of a system under a load in a given range of frequencies. Engineers can virtually replicate common industry shaker table tests that are required for electronics products.

Electronics products and components can be subjected to static and dynamic loads with nonlinear behavior and material properties. Dynamic analysis can simulate the dynamic response of structure and components subjected to time-dependent loads and displacements. Time-dependent calculation of displacements, as well as stresses and strains in one or multiple solid bodies, is possible and in contrast to static analysis, inertial effects can be accounted for. In the post-processor, it is possible to analyze single-time steps as well as the dynamic performance over time. Similar to static analysis, engineers can evaluate deformations, or critical stresses and modify designs based on these insights.

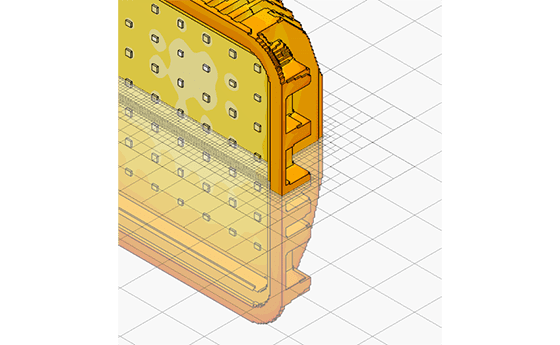

Enables multiple design CAD geometries simulated in parallel with robust CAD handling and automatic meshing.

Allows for the simulation of heat transfer between solid and fluid domains by exchanging thermal energy at the interfaces between them. The Immersed Boundary Method (IBM) is based on a cartesian grid in which the geometry gets immersed into. Therefore it is resilient to geometrical details and does not require CAD simplification even for very complex models.

SimScale meets and in many cases exceeds the accuracy of traditional CAE simulation tools (speed does not compromise accuracy).

SimScale takes away the complexity of preparing imported geometry and allows designers to focus on analysis by providing an intuitive, automated, and robust UI that reduces person-hours required for simulation, and also makes it accessible to non-experts/designers.

Customer Success

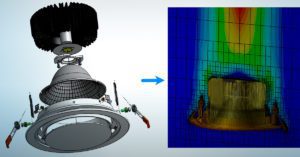

Raycore Lights used cloud-based thermal analysis to shorten the design and prototype cycle when developing a new product for overhead lighting applications. They tested 8 design iterations and ran 5 simulations in parallel.

Check out all the success stories of our customers in the electronics industry, including EASEE, ANYbody, OnLogic, and Forwiz System Co.

See All Stories

Sign up for SimScale

and start simulating now