Modern electronic devices are becoming increasingly smaller while at the same time improving in their performance. Although incredible strides have been made in making electronics more power efficient, thermal management is more important than ever given increasing power density/small form factor requirement, largely driven by the ubiquity of handheld devices. There are many examples where global electronics companies carried out expensive product recalls due to overheating (or even exploding!) devices.

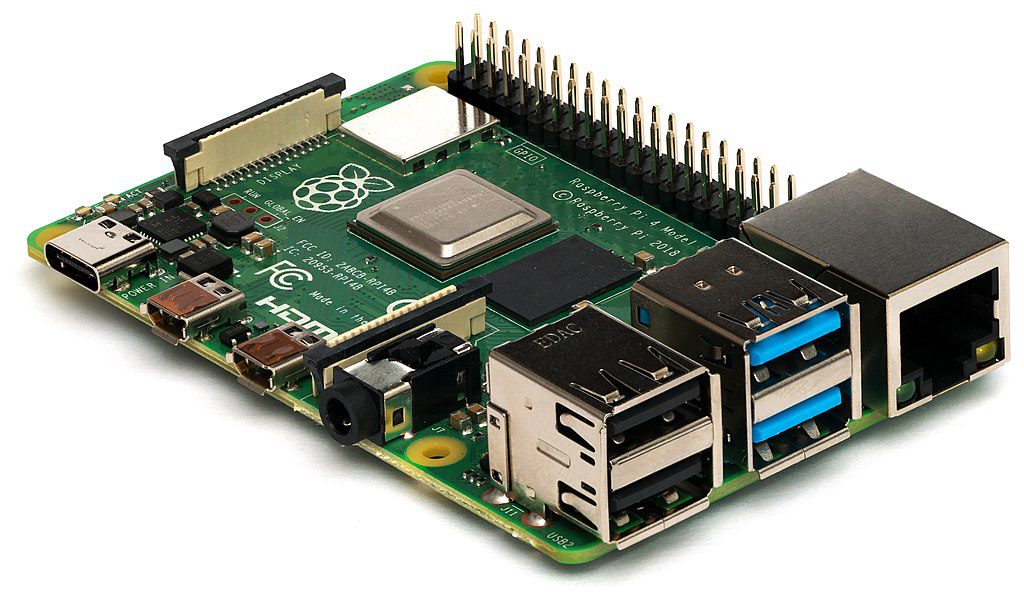

Simulation is an essential part of designing thermal management in electronics. It allows engineers to evaluate their designs by quantifying the temperature distribution throughout the device depending on the materials, geometry, air or coolant flow characteristics, and the power consumption of the components. Simulating electronics cooling has a unique difficulty that does not occur with other thermal simulations. Electronic components have many little parts and details such as components, pins, chip markings, plate-through holes, etc. We can see this when considering a typical printed circuit board (PCB) assembly shown in the image below.

Source: Michael H. („Laserlicht“) / Wikimedia Commons

These components are too small to influence the heat transfer and flow behavior. It is possible to include them in the simulation, however, this often leads to low-quality meshes or very resource-intensive simulations which often fail. Therefore, a typical step in electronics cooling simulation is to defeature the CAD model so that it can be meshed easily. Unfortunately, defeaturing and CAD cleanup are tedious and extremely time-consuming tasks. SimScale offers an analysis method capable of dealing with complicated or unclean CAD models.

Using the Immersed Boundary Method for Electronics Cooling

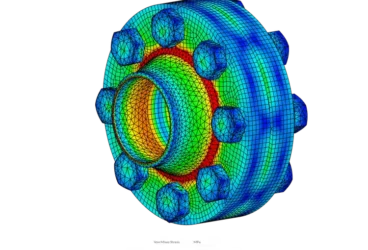

The Immersed Boundary Method (IBM) is a new analysis type available on the cloud-native simulation platform SimScale. It allows for the simulation of heat transfer between solid and fluid domains by exchanging thermal energy at the interfaces between them. While in standard CFD and FE simulations the domain is discretized using body-fitted meshes, IBM uses Cartesian meshes where the elements are aligned parallel to the Cartesian directions. The geometry of the simulated device is immersed into the Cartesian mesh. The mesh is resilient to geometrical details and does not require CAD simplification even for very complex models. A visual example of a Cartesian mesh used in IBM can be seen in the image below.

By using the IBM solver in SimScale, an engineer can completely skip the painstaking CAD-cleanup phase of the simulation preparation which can often take several hours. This is a massive gain in time and effort and just another way in which SimScale enables engineering innovation by making simulation technically and economically accessible at any scale.

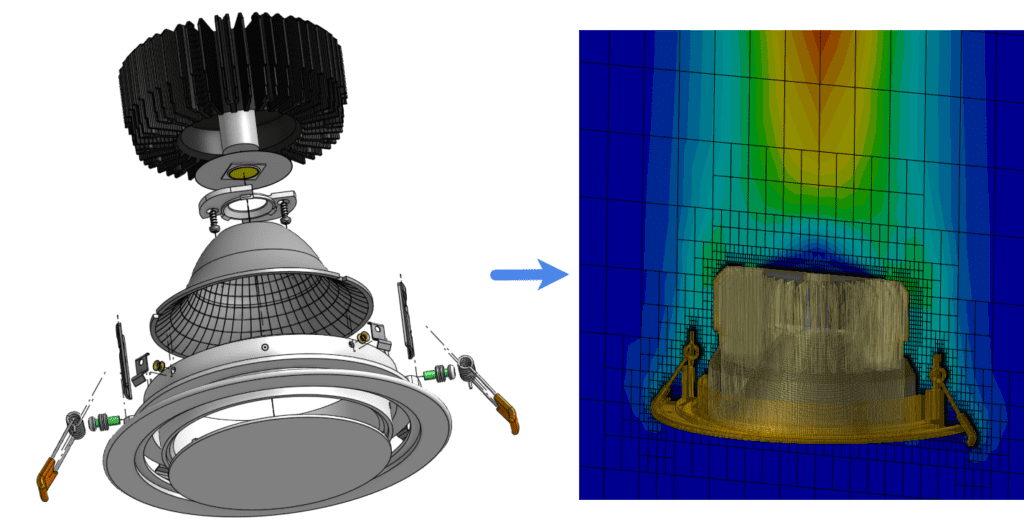

Use Case: Thermal Performance of Alternative Designs of an LED Lamp

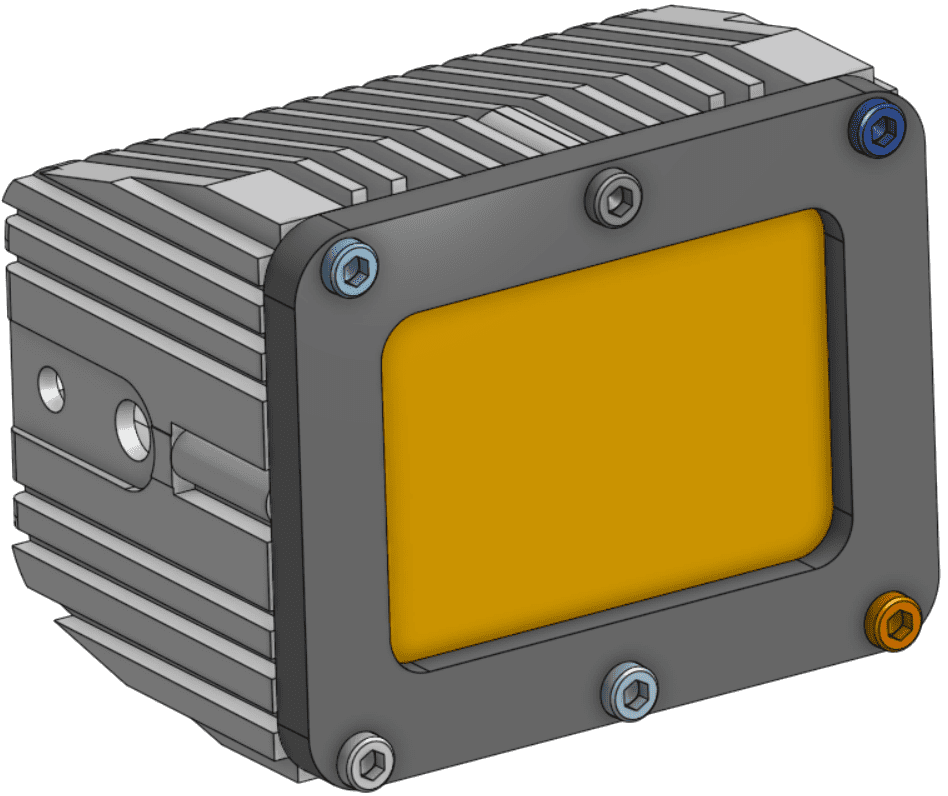

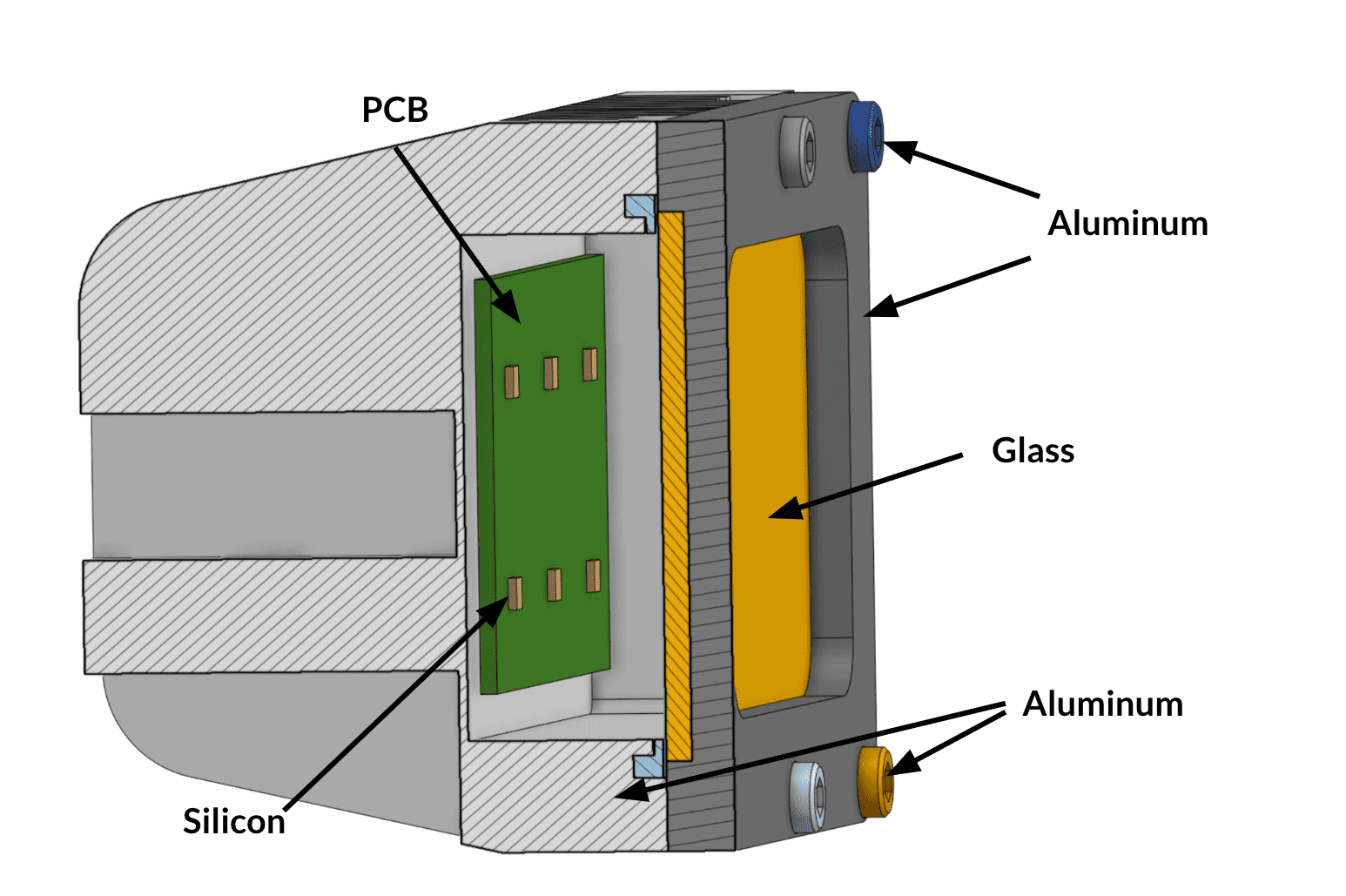

To showcase the new IBM solver, we will consider the heat transfer behavior of the LED lamp shown in the image below. The lamp is designed as a work lamp for industrial applications where the presence of dust may be an issue. Therefore, the lamp is watertight thanks to the gasket which can be seen in the image in light blue. The lamp relies on passive heat sinks and natural convection for cooling.

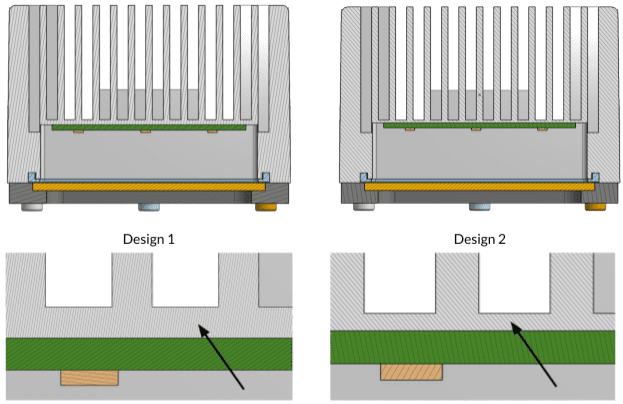

The image below shows the two design alternatives that shall be considered here. The subtle difference between the two lies in the thickness of the base plate of the heat sink. The two designs are otherwise identical.

Simulation Set Up

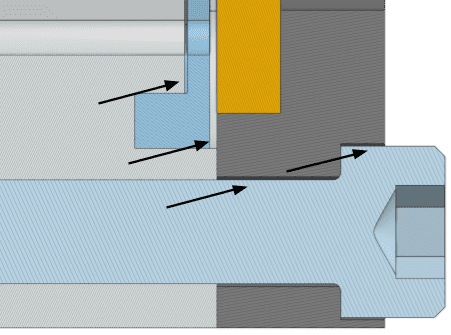

One of the advantages of SimScale is how easy it is to set up a simulation. IBM underlines this by removing the necessity to clean up the CAD. In this case, for example, we have small gaps around the fasteners and gaskets as in the image below. These details are typical of manufacture-ready and also early-stage design CAD. These are normally things that would have to be defeatured to avoid low-quality body-fitted meshes, however, the IBM solver easily deals with these kinds of details.

CAD associativity is a new feature in SimScale which allows engineers to design and simulate iteratively. When switching between different geometries as in this case, all materials, boundary and initial conditions, and energy sources are reassigned automatically. This makes it very efficient to carry out comparative or parametric simulations. Currently, CAD associativity is possible with Onshape® and Solidworks®, for which SimScale also offers plugins for the direct transfer of CAD files from within the respective CAD packages.

Completing the setup requires only a couple of steps:

- Material assignment: it is possible to define orthotropic thermal conductivities to capture the properties of PCB

- Bounding box: a large enough cuboid is defined around the model to capture the thermal plume forming above the lamp

- Boundary/initial conditions: it is not necessary to define boundary conditions in the IBM solver when simulating external flow. The walls of the bounding box are considered to be open

- Heat sources: each LED dissipates 3 W of thermal energy

- Mesh: the beauty of a Cartesian mesh is its simplicity; therefore, its definition is also straightforward. You can usually leave the default settings and mainly work with refinements in case adjustments are needed.

- Click Run!

- Switch Geometry

- Click Run!

SimScale is completely cloud-native. This means that the simulation does not run locally on your computer but on remote servers. It is possible to run an unlimited number of simulations in parallel. Since for every simulation a new virtual machine is created, one simulation takes the same time as ten simulations. So it is possible to consider twenty different designs and get results in just over an hour, which is approximately the duration of the simulation presented here. Furthermore, there is also no need to install or maintain any software or hardware since SimScale runs entirely in your browser.

Results

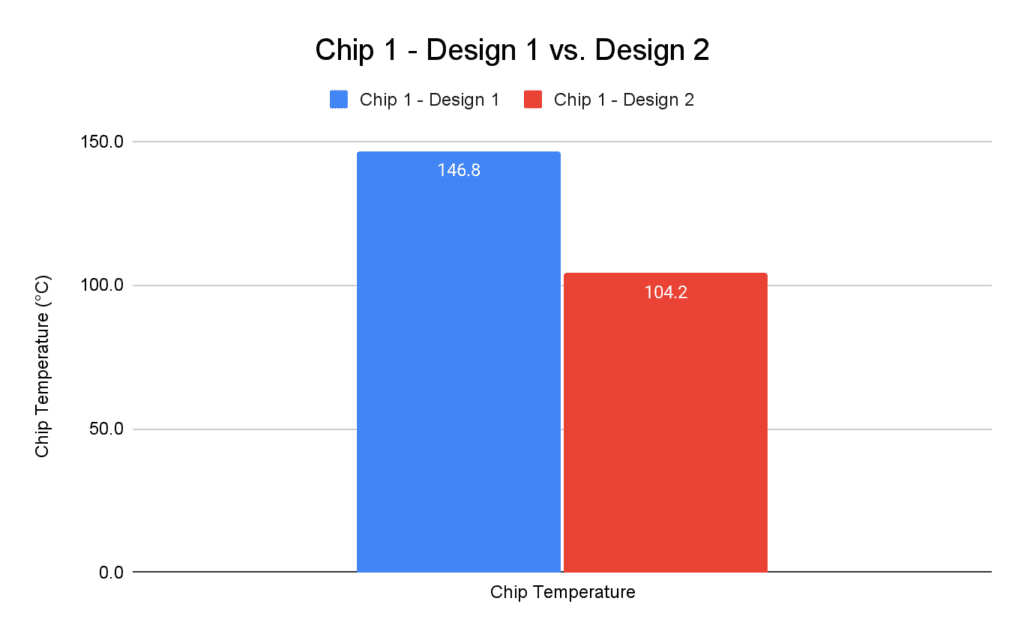

In the chart above, we can see the temperature values of the LED chips for the two designs. The first design has significantly warmer chips. Apparently, the thicker heat sink traps too much heat, while the thinner heat sink is more efficient in transferring heat to the thermal plume.

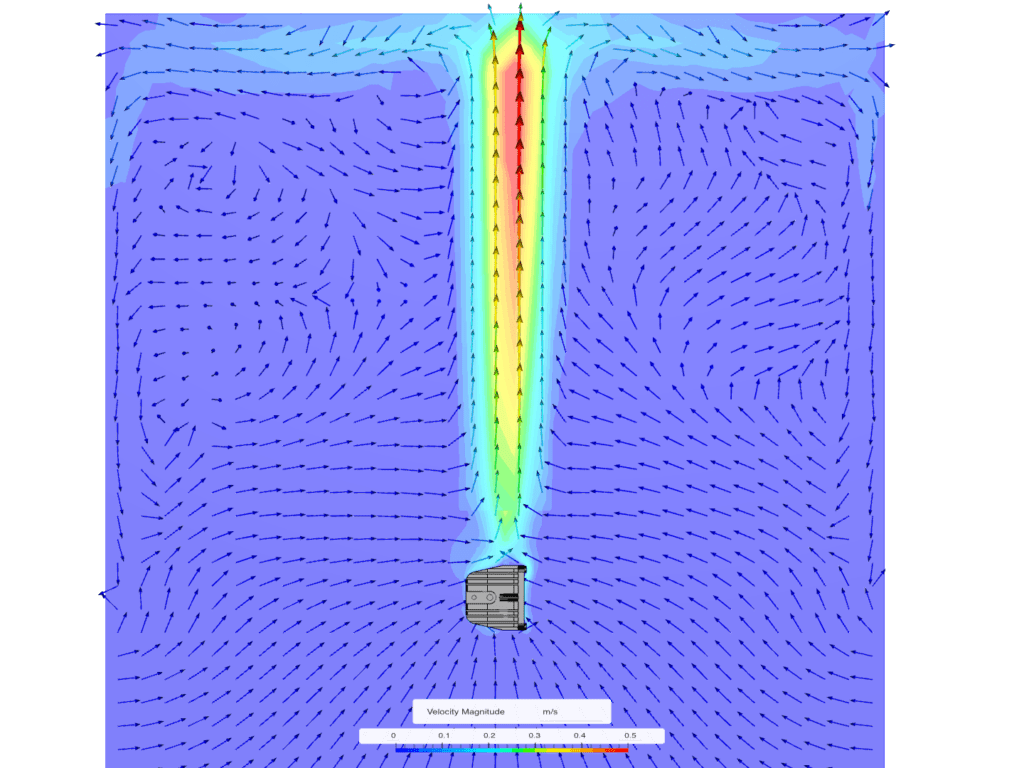

Moreover, we can also have a look at further results to carry out a sanity check on our simulation. In this next plot, we visualize the thermal plume forming above the lamp. Typically the flow velocity of the thermal plume in natural convection cases is in the order of 0.5 m/s to 1.5 m/s, which is also what we see here.

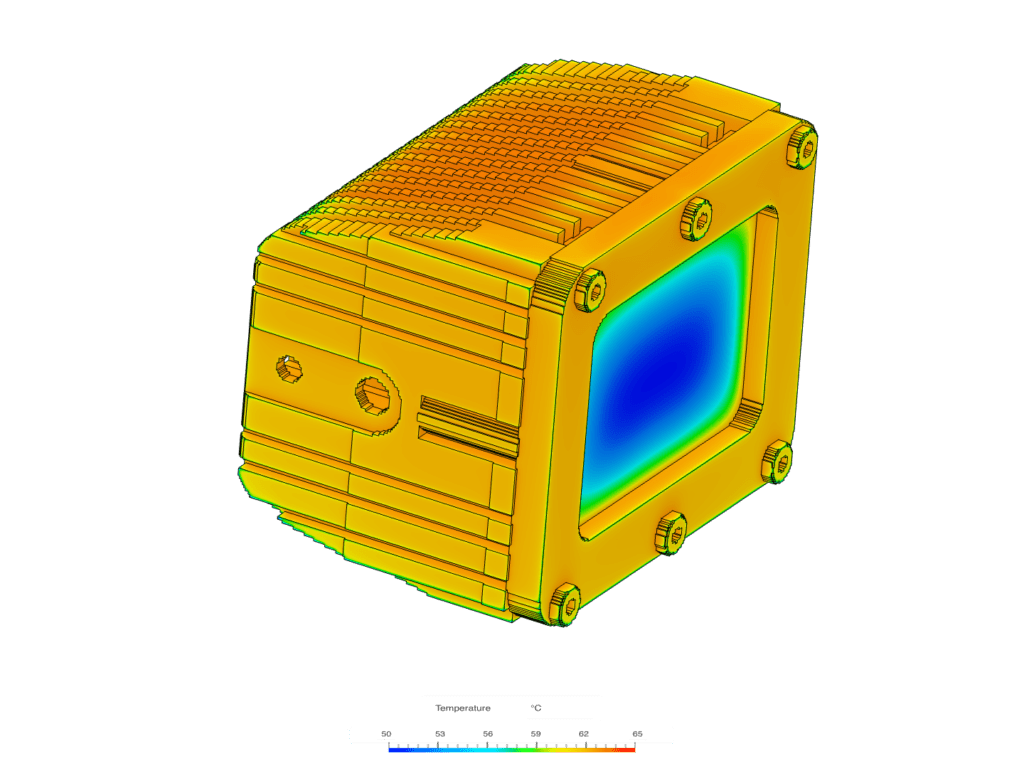

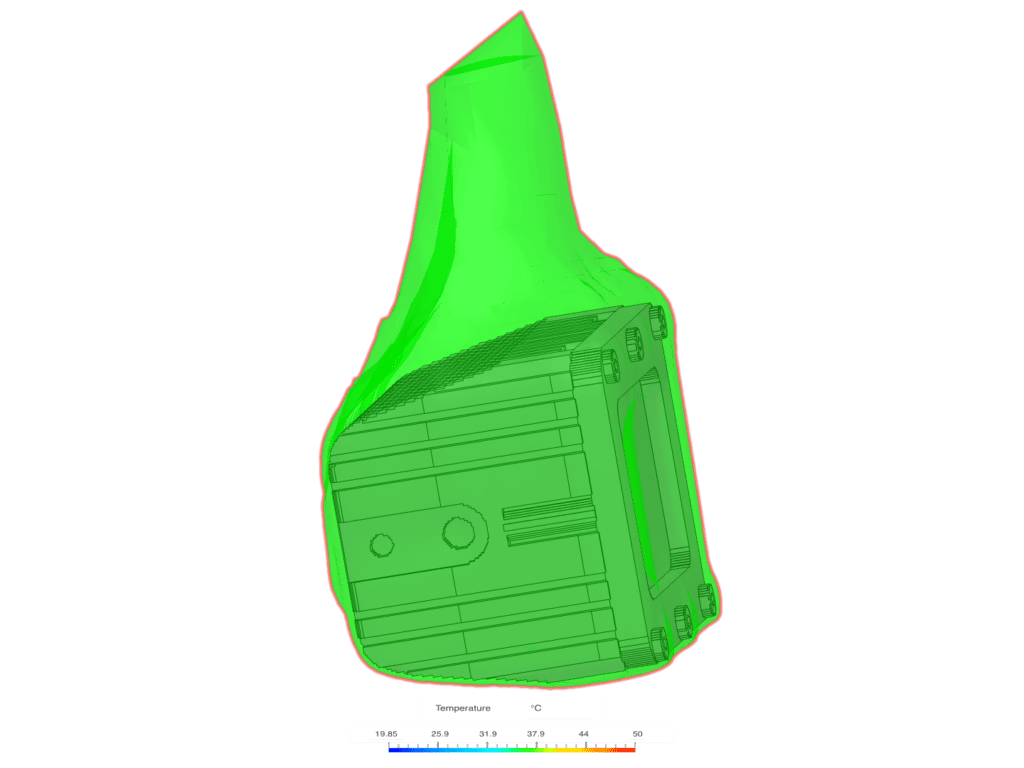

As the lamp may be installed inside a wall or cupboard it is important to know both the temperature on the surfaces of the lamp and the temperature of the air around the lamp. There are often safety specs that define a minimum distance to the wall if the air around the lamp is too high. To make sure we are fulfilling these specs, we can look at the temperature distribution on the surfaces of the lamp and also in the air around the lamp. Both plots can be found in the two images below. In the latter of the two plots, we are showing an isosurface corresponding to 35 °C. The volume inside this surface will be hotter than 35 °C and the temperature outside this surface is below 35 °C.

Leveraging the Cloud for Electronics Cooling

SimScale enables engineers to innovate more quickly by making simulation more accessible. The IBM solver makes CAD clean-up obsolete which is an extremely time-consuming (and very annoying) exercise. Additionally, CAD associativity allows for rapid swaps of geometries without having to redo the simulation setup. Coupled with the unlimited and parallelized computing power of the cloud, an engineer using SimScale can innovate and iterate much more quickly.

Learn more about SimScale’s state-of-the-art IBM solver for fast, easy-to-use, and accurate modeling of thermal management in electronics in this on-demand webinar: