Energy Machines™ is a leader in the design, implementation, and operation of integrated energy systems for buildings. Buildings are a growing climate problem, accounting for over 28% of global CO₂ emissions. Energy Machines is building a future in which buildings accelerate the world’s transition to sustainable energy by turning every building into a high-performance net-zero energy building. These buildings generate, store, and reuse their power with an integrated system of alternative energy sources, advanced controls, demand reduction technologies, and more. The company has expertise in combining heating, cooling, ventilation, and solar and wind power into one connected system with unique benefits. Unlike traditional HVAC installations that are powered externally and operate separately within the same building, their innovative system synchronizes all building services and utilities for optimal performance.

Energy Machines offers turnkey solutions to the architecture, engineering, and construction (AEC) market using a mix of alternative energy sources including wind turbines, sustainable design services, and cloud-enabled monitoring, and verification (M&V) software. Optimizing multiple technologies in real-time means that careful consideration must be given to the design and performance of each component in the building. At the system’s core is a custom-built cloud platform that collects real-time data across buildings and sites, enabling actionable insights that help facilities’ operations. The remote access app allows users to monitor performance from anywhere. At the same time, the visual dashboard provides a complete system overview that is used to showcase a building’s climate performance in real-time.

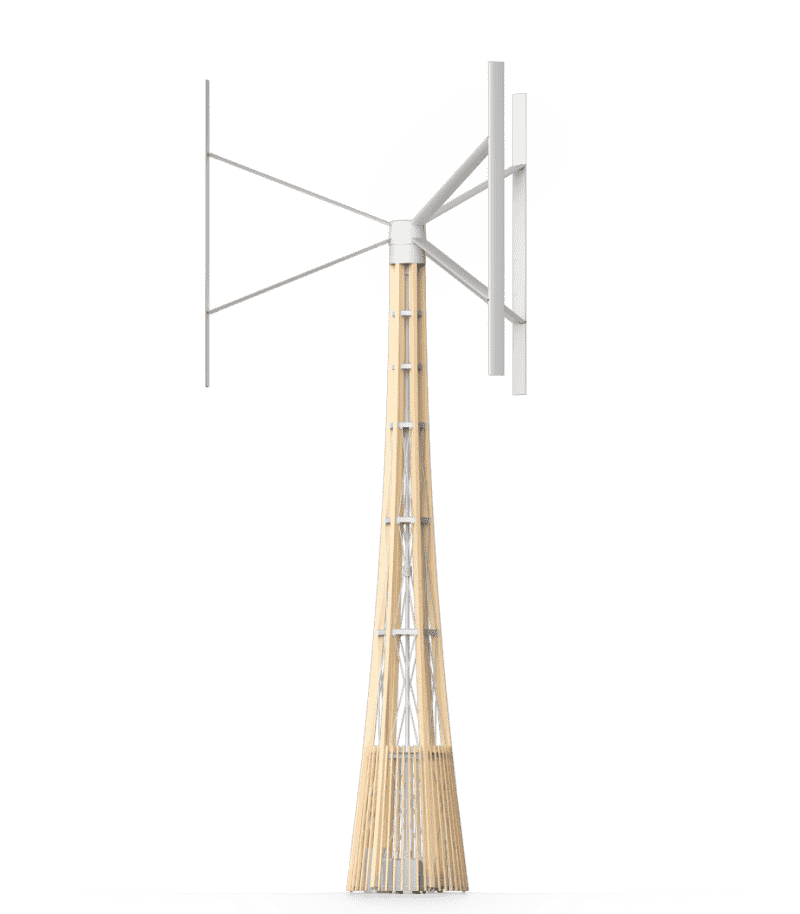

Powering the building as sustainably as possible means using locally-generated electricity. Through its subsidiary EM Wind, Energy Machines uses a combination of purpose-built vertical wind turbines designed for rooftop and ground use and solar panels that provide electricity and hot water (Solar PV and solar thermal). Excess power can be stored in batteries or sold back into the local grid. Additional technologies used alongside wind and solar power include heat pumps, high-efficiency air handling units with heat recovery and underground seasonal thermal energy storage. Vertical axis wind turbines are a component of the energy machine value proposition. Drag turbines and lift-type wind turbines are used depending on the building type, location, terrain, and climate.

EM Wind has been testing and validating its wind turbines’ aerodynamic, power, and structural performance using the CFD and structural analysis types integrated into the SimScale platform. A team of ten engineers at EM Wind is involved in developing and testing wind turbines. Engineers with simulation expertise use SimScale to perform parametric studies on various aspects of wind turbine design under changing wind speed and direction. Their preferred simulation workflow is Creo® (CAD) to SimScale and using CAD mode for extracting the fluid domain and making minor edits to the geometry. CAD mode is a feature in the SimScale platform for basic CAD operations that allows engineers to make simple edits without having to re-import modified CAD files each time a small change is required.

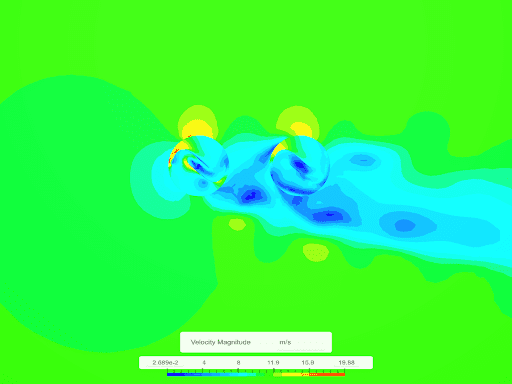

The drag (savonius) turbines can be placed in areas with high turbulence and unsteady flow, such as rooftops in dense urban areas. They are used to supplement power for commercial or residential buildings in windy locations, and their performance is less dependent on wind direction because of their drag-induced aerodynamic design. They come in 100 and 250 Watt power outputs and are designed to withstand stormy conditions. The rotor of the drag-based turbine has blades made from UV-resistant plastic attached to the rotating shaft with stainless steel support brackets.

The lift-based turbines use aerodynamic lift generated on highly optimized symmetric NACA airfoil blades to induce rotary movement. These turbines are very efficient and can easily scale to larger sizes. They often require a tall mast (tower) for placement to catch the higher wind speed and operate more efficiently in locations with a prevailing wind. They come in sizes of 2, 10 and 25 KW power outputs placed atop towers at 8.4m, 12m, and 15m, respectively. The rotor of the lift turbine has blades and struts made (extruded) mainly from aluminum.

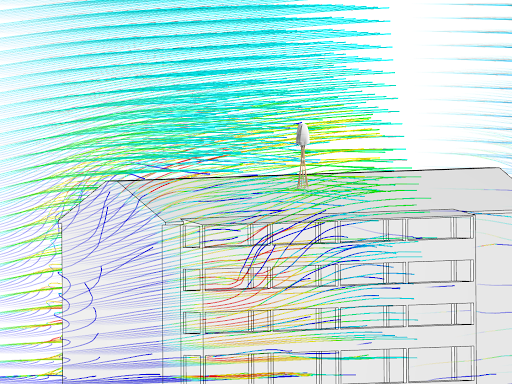

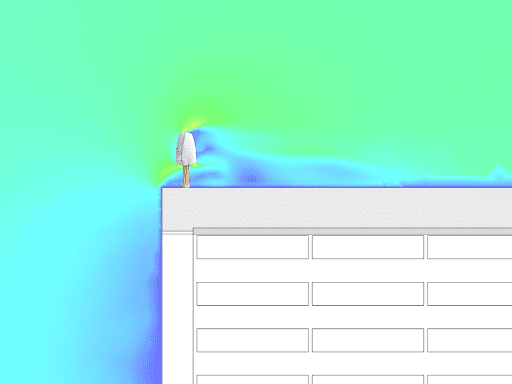

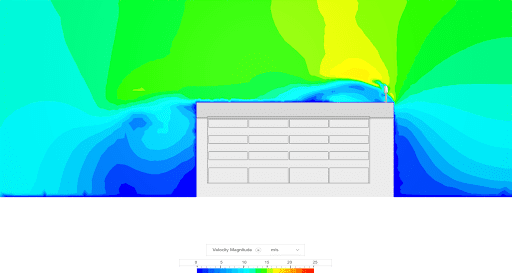

EM Wind has been employing simulation for various types of design analysis. For the drag turbines, they have used SimScale for turbine blade design and optimization, assessing rotor sizes, simulating its performance at multiple wind speeds and tip-speed ratios, and simulating them on 3D models of buildings. EM Wind can identify areas with higher wind speeds on and around buildings using CFD. This allows EM Wind to extract as much power from the turbine as possible and adds to the financial viability of using wind turbines, especially now that feed-in-tariffs and monetary subsidies have decreased in many EU countries. It is also critical in understanding turbine performance in high-risk conditions such as storms and gusts. EM Wind has modeled various building typologies such as residential, industrial warehouses, and commercial greenhouses. Direct outputs (force plots in the post-processor) of moments and forces using SimScale also assist in targeting appropriate cut-in speeds for the rotors, needed to overcome inertia and get the turbine rotating from stationary. These simulations have resulted in cut-in speeds of 3-4 m/s that fit in with the intended annual average wind speeds of target markets.

“Being able to run many simulations in parallel on the cloud has been very useful and saved us a lot of time. Using SimScale has reduced our wind turbine testing by weeks. By simulating on the cloud with more cores than on a personal computer, we have been getting results about 3x quicker than if we run it locally, as before. We also save time on how quick it is to set up many similar simulations by duplicating and changing geometry or other input parameters.

Julia Arnardottir

Mechanical Engineer and Simulation Expert at EM Wind

EM Wind has vertical axis wind turbines of varying sizes, some of which require tall masts to capture higher wind speeds with more steady flow. The mast or tower is a critical component of the wind turbine assembly and must be correctly designed and sized. Its load-bearing properties must be carefully selected with the required safety margins, as must its frequency response to excitation from the wind and rotation of the turbine. Any excitation beyond safety limits can result in deformation and damage. A modal (frequency) analysis can help determine the eigenfrequencies (eigenvalues) and eigenmodes (mode shapes) of a structure due to vibration. The results are essential parameters for understanding structures and products subject to unsteady conditions. The resulting frequencies and deformation modes depend on the structure’s geometry and material distribution.

EM Wind uses low embodied carbon wood masts for their sustainability credentials. Although wood masts offer good structural properties, they have been known to break on vertical axis wind turbines when an eigenmode of the tower has been excited. Therefore, EM Wind is carefully performing various simulations and structural analyses in SimScale, such as vibration analysis on the tower of the 10kW vertical axis wind turbine that has a rotor diameter of 7.6 m, a mast height of 12 m, and a max rpm of 100, to prevent similar damage.

Determining the eigenfrequencies from a vibration analysis is an essential part of the structural design of wind turbine towers. Eigenfrequencies are specific frequencies at which a structure is likely to be ‘excited’ and hence, vibrate. When this happens, the structure can deform into a corresponding shape specific to that frequency, called an eigenmode, and can cause damage or have unintended consequences such as noise. A comprehensive study using SimScale led to five towers (mast) concept designs being developed and assessed under many structural conditions. The table below shows the original tower design and the new steel alternatives. Results for deformation and an eigenfrequency plot are shown for tower concept 6.

EM Wind and Energy Machines plan to increase simulation use to broader applications in the architecture, engineering, and construction industries. Using the lattice Boltzmann (LBM) integrated solver Pacefish© in the automated pedestrian wind comfort (PWC) tool in the SimScale platform, EM Wind can now perform site feasibility studies for microclimate and wind resource assessments using the integrated climate database from Meteoblue, accessed directly from within SimScale. The PWC tool is a fast and accurate tool intended for early-stage design studies that lend itself to use by architects and engineers alike. This tool performs transient wind analysis on city-scale models, an order of magnitude faster than conventional CFD solvers. It will also allow EM Wind to evaluate many clusters of wind turbines in an array instead of single turbines on roofs or open fields.

The cloud-native nature of SimScale means it can be linked to Energy Machines’ cloud tools for building optimization and monitoring using the SimScale API. Additionally, with Energy Machines’ innovative HVAC solutions, SimScale can be used to calculate indoor thermal comfort and air quality, building fabric heat loss, and many other internal environmental variables such as CO2 concentrations.

Sign up for SimScale

and start simulating now