The ILF Group is an international engineering and consulting firm that has been helping its clients successfully to execute technically demanding industrial and infrastructure projects for more than 55 years. With over 2,600 highly qualified employees at more than 45 office locations across five continents, the companies of the ILF Group have a strong regional presence. This enables ILF to locally interact with clients and other project parties. At the same time, close cooperation within the network of the ILF Group makes it possible to call upon leading international experts and make use of their special experience, processes, and tools. This combination of local presence and international expertise, as well as ILF’s complete independence – as a privately-owned company, having no affiliation to manufacturers, suppliers, or financing institutions – ensures that clients’ needs are best met. ILF’s main business areas are: Energy & Climate Protection, Water & Environment, Transportation & Urban Spaces, and Oil, Gas & Industrial.

In 2014, ILF established an office in Thailand in order to serve the South-East Asian market. Since then, ILF has successfully met the requirements of its clients, continuously building a market presence as well as client relationships and trust within this region of the world.

ILF Consulting Engineers (Asia) Ltd. maintains an engineering center in Bangkok, Thailand, and provides German-Austrian quality engineering and consultancy services in the South-East Asia region and beyond. Among others, ILF Asia focuses on the hydropower and solar power industry, and in a short time, ILF Asia was involved in over 60 hydropower and solar power projects in Thailand, Laos, Myanmar, Indonesia, Malaysia, Vietnam, and the Philippines.

Among these projects, ILF carried out the redesign, detailed design, and supervision of the Nam Emoun Hydropower Project with an installed capacity of 130 MW and with over 20 km of tunnels, situated in Laos. ILF also supported the design and construction of the 100 MW Sao Mai solar plant in Vietnam. Other recent involvements are the engagement as government engineer for the Nam Ou 1, 3, 4, and 7 Hydropower Projects with a combined installed capacity of 740 MW and the Feasibility Study of the Saravan Downstream Hydropower Plant with a design capacity of over 2,400 MW.

In line with its commitment to contribute to sustainability, ILF puts the United Nations’ Sustainable Development Goals (SDGs) at the heart of its business activities. The SDGs provide the framework for ILF’s endeavor to create a more livable and sustainable future, characterized by safe and healthy living conditions, for present and future generations. Population growth and the ongoing endeavor to improve living standards are leading to an increase in the global demand for energy. The limited availability of fossil fuel resources and the environmental problems resulting from the use of these resources make transitioning towards renewable forms of energy imperative. In this context, hydropower stands out as being a sustainable and economically viable source of energy in the long term.

Within the field of hydropower and pumped storage, ILF Consulting Engineers ranks among the leading design and consulting companies and has done so for many years. ILF actively supports the sustainable transition to renewable forms of energy by providing integrated, interdisciplinary services, from project initiation, design, and tender, to commissioning and start-up, for hydropower generation and storage projects of any type and size. Whether these projects involve the construction of a new run-of-river, diversion, storage, or pumped storage plant, or rehabilitation of existing installations, ILF always places emphasis on developing individual solutions that meet the most stringent quality standards and take complex framework conditions into account.

Lex de Rijk is a Project Manager at ILF Consulting Engineers (Asia) with a wealth of experience and expertise in numerical calculations, such as computational fluid dynamics (CFD). He has investigated numerous hydraulic problems both in river estuaries with water-resource retaining structures, and construction designs for hydraulic purposes, using a variety of CFD software. His modeling competencies are adjoined by experiences in conducting due diligence, pre-feasibility, feasibility, and detailed design studies of hydropower plants in South-East Asia and he has a proven track record of delivering high-quality work as a project manager and ensures that projects are completed on time and within budget. Lex has been using SimScale to model and optimize hydraulic structures of hydropower installations, as well as hydraulic systems of thermal power and mining installations amongst projects in Thailand, Laos, Myanmar, Indonesia, Philippines, Vietnam, Chili, and Peru.

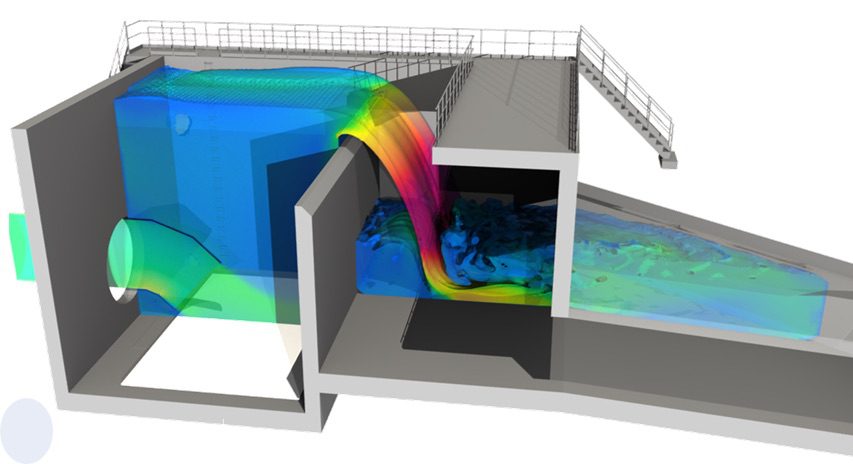

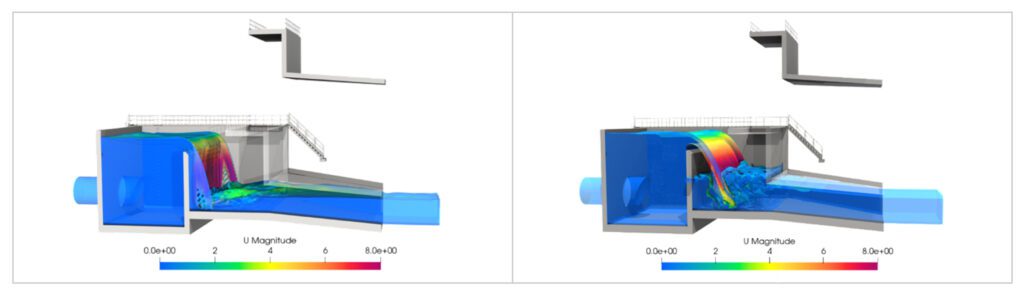

Particularly, structures that involve complex flow patterns, usually found in structures that involve a transition between free-flow and pressurized conditions, are investigated in detail using the CFD simulation tools. Aspects such as energetic losses, aeration of flows, stability of transitioning flows and rapids, loads, and scouring on surfaces are investigated. Robust, slim, and cost-effective designs are aimed for through the optimization of the hydraulic structures by CFD.

Advanced CFD tools enable a better understanding of fluid behavior, leading to safer, more efficient, and optimized designs of hydraulic structures.

Lex de Rijk

Project Manager, ILF Asia

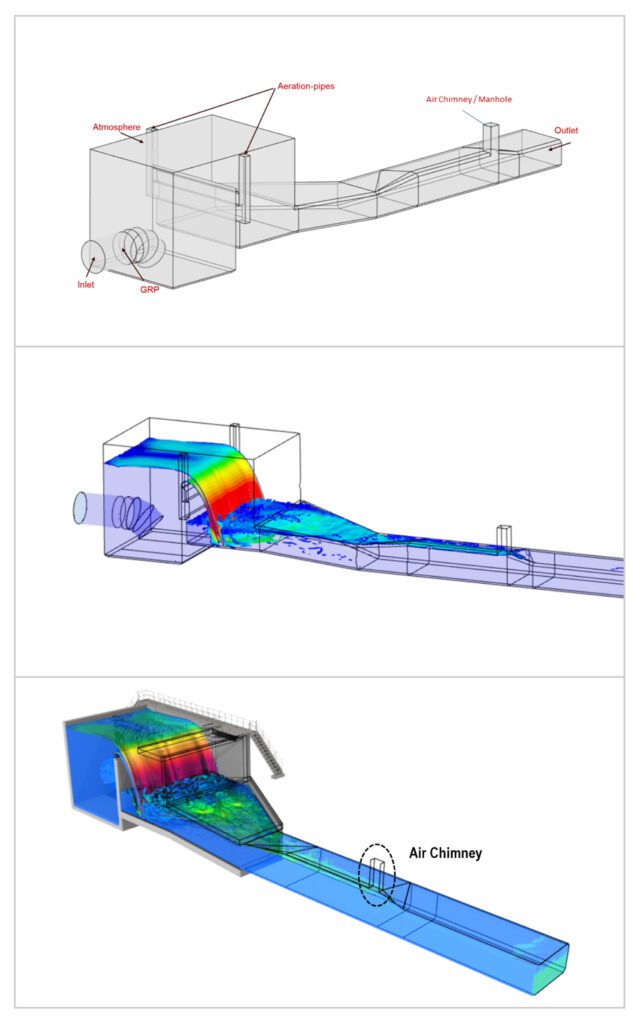

A siphon pit is a hydraulic structure that may be used to seal the pressurized section of water systems on the downstream end, providing a stable back pressure during operation. The case study of the siphon pit was conducted within the design phase of a cooling water system of a combined cycle gas-fired power plant. The pipe end of the cooling water system enters the pit in its upstream basin. The basin is separated by a sharp-crested weir structure, resulting in a water drop within the downstream cavity of the pit. A subsequent transition section leads the water to a box culvert conveyance channel that functions fully submerged under normal operational conditions. Tidal variations at the downstream end of the outfall conveyance line result in a variable steady water level within the downstream cavity of the pit.

The siphon pit was hydraulically analyzed using the dual-phase fluid dynamics solver in SimScale. The velocity profiles of the water flow and areas of turbulence and air-bubble formation were obtained. Within the structural boundaries, several optimization facets were implemented leading to further robustness of the structure and stability of the hydraulic performance. To come to such improvements an in-depth analysis is conducted through numerous optimization iterations using SimScale. The process resulted in a number of benefits, including:

The hydraulic optimization of the siphon pit was successfully conducted and demonstrates the benefits of using SimScale for the improvement of the safety, robustness, and performance of hydraulic structures.

The downstream back-pressure in the box culvert varies due to tidal variation impacts. The siphon pit was simulated at the worst-case conditions downstream in terms of aeration, which corresponds to the minimum operational water elevation. To de-aerate the fluid inflow of a pressurized 2 km long box culvert, the initial design containing the manhole has been transformed into an effective air chimney by opening the top cover and increasing its height to avoid water splash-out under high water elevation conditions. The ceiling of the initial box culvert section has been adjusted, through several design iterations, to provide the chance for air to conglomerate within the high-ceiling section and efficiently detrain from the water conveyance line at the air chimney.

In hydraulic engineering, a nappe is a sheet or curtain of water that flows over a weir or dam. Nappe aeration is important for the stability of the nappe itself, the weir capacity, and for increased stabilization of the headwater surface. Aeration of a nappe is simply conducted by providing atmospheric pressure at the hind-nappe air pocket. To achieve nappe aeration several options are available, out of which aeration pipes were introduced within the presented design. These pipes are embedded in the side walls of the concrete structure with one open end positioned at the air pocket, and the other end above the structure in the open air.

We found SimScale easy and intuitive to get started with and it required a short learning curve to compute meaningful results. Having acquired prior experiences using Openfoam on local workstations, the benefits of SimScale are found in its easy access of this web-based application, an easy-to-use interface for model setup and post-processing of results, and the ability to run simulations in parallel with a vast amount of CPU’s if required. All of this has led us to modeling comfort and most importantly ‘time-saving’. We typically save around 50% of our time by using SimScale compared to what we have used before.

Lex de Rijk

Project Manager, ILF Asia

The key advantage to using SimScale comes with its powerful simulation features in the cloud. It makes it easy to rerun cases with different inputs and compare scenarios and design iterations. This has been especially useful at the early stages of designs and allows the engineers to consider new techniques and experiment with novel ideas in an otherwise very conservative and risk-averse industry.

Lex de Rijk, M.Sc. graduated in Mechanical Engineering from the Eindhoven University of Technology in the Netherlands, with a specialization in thermodynamics for energy systems. He has seven years of experience in application-wise product development for market-readiness within the Marine Renewables sector. He acquired a wide range of technical skills in the design and R&D of hydraulic systems within the renewable energy sector over the last ten years e.g., analytical & numerical modeling, hydraulic model experimentation, commissioning and testing of full-size prototypes as a field engineer, and conducting energy yield assessments.

Sign up for SimScale

and start simulating now