Part of Larsen & Toubro multinational company, L&T Construction is India’s largest construction organization and ranked among the world’s top 30 contractors. Several of India’s prized landmarks—edifices, structures, airports, industrial projects, flyovers, viaducts, water and power infrastructure projects carry L&T’s signature. Water and Effluent Treatment is an independent company (IC) of L&T Construction. Water and Effluent Treatment division deals with water supply, waste water treatments, effluent treatments and lift irrigation projects.

The Challenge

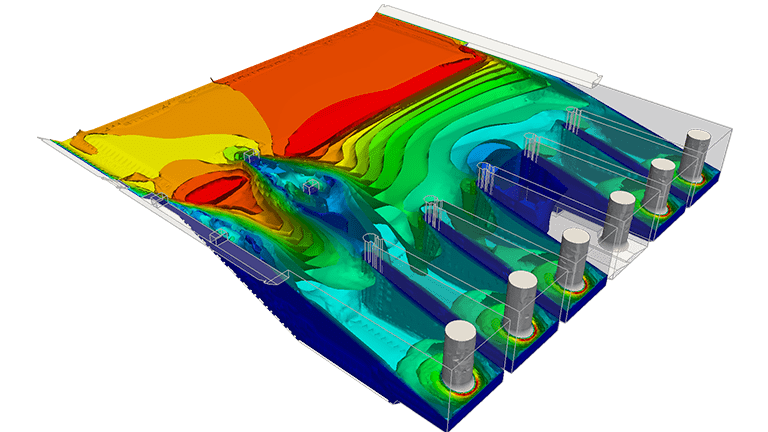

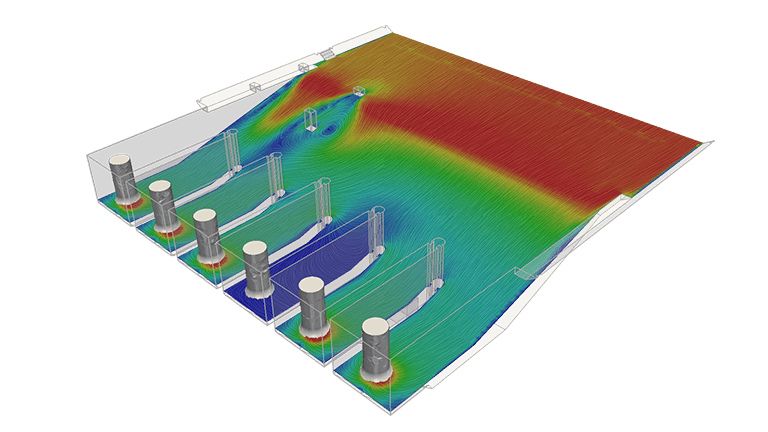

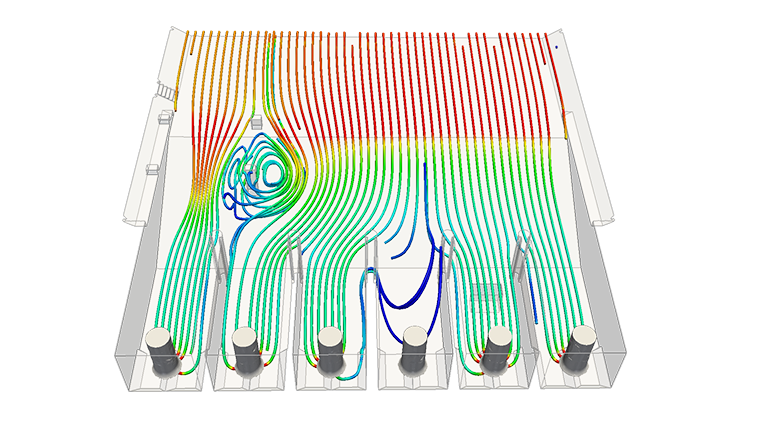

For lift irrigation projects, the structures in the sump cum pump house should be designed to ensure that the flow reaching the pumps is free from any vortices, especially submerged vortices.

The flow can be analyzed using computational fluid dynamics (CFD), which was the reason why the L&T decided to purchase SimScale. Because SimScale is based on cloud computing, its accessibility and cost-effectiveness provided an added advantage. Additionally, by not binding them to a single computer, SimScale made it easier for the team to demonstrate the projects to their clients.

Being a cloud-based software, SimScale omits the necessity for multi-core processor systems, ensuring cost-effectiveness and time saving with ease of accessibility.

Md Sujaat Ali

Senior Mechanical Design Engineer

Using SimScale, L&T first checked their if the design met HIS standards with respect to velocity and the extent of flow circulation (vortex formation). They then made the required modifications to make it suitable for pump operation. For the simulation, the fluid flow was considered to be incompressible and a hex-dominant parametric mesh was selected with multiple types and methods of refinements.

The main challenge was to ensure that the flow reaching the pump was free from surface and sub-surface/strong surface vortex.

“SimScale’s user-friendly interface simplified the task to a great extent. Moreover, SimScale’s customer support is admirably good. The online support and sharing of project facility is one of the features that separates SimScale from other CFD software. Any problem faced during any point of time in software handling, was duly solved by the customer support team of SimScale,” mentioned L&T Construction’s team.

Until now, more than 50 simulations have been performed for three different projects. With 32 cores, it took approximately 60 minutes for a simulation to run. For all the projects, the online SimScale post-processor was used, which includes filters for velocity vectors, streamlines, and calculator fields.

With SimScale, the L&T team reduced the time to solve the problems in the sump geometry by approximately 15 days. Moreover, the cost saved was of around $38,000 for four projects. The company is planning to incorporate SimScale for waste water treatment and effluent treatment projects in the future.

“The online support and sharing of the project facility is one of the features that separates SimScale apart from other commercial CFD tools,” said Md Sujaat Ali.

Sign up for SimScale

and start simulating now