The car of the future is going to be autonomous, connected, electric, and shared, and at the core of this automotive industry’s growth are Tier 1 suppliers. Yet, two prerequisites underlie the race to the forefront: Accelerating Innovation and Increasing Efficiency.

The automotive industry today is led by consumer perception, understanding, and expectations. With sustainability, AI, and efficiency being the reigning themes in almost every discussion, consumers are becoming increasingly aware, inquisitive, and critical of the vehicles they are purchasing, especially the younger, technically savvy generations. This is enabling particular technologies to rise in popularity and drive the market for at least the next decade.

These emerging technologies have led OEMs, and in turn Tier 1 suppliers, to buckle down and rush to optimize their processes so as not to miss out on market share. As consumer behavior gradually changes, vehicle sales are changing, too – determined by product quality [1], sustainability, purchasing experience, and brand. Moreover, these changes have gone further upstream to impact the design, manufacture, and supply of automotive parts and systems. That is why Tier 1 suppliers are racing to increase engineering efficiency and accelerate innovation.

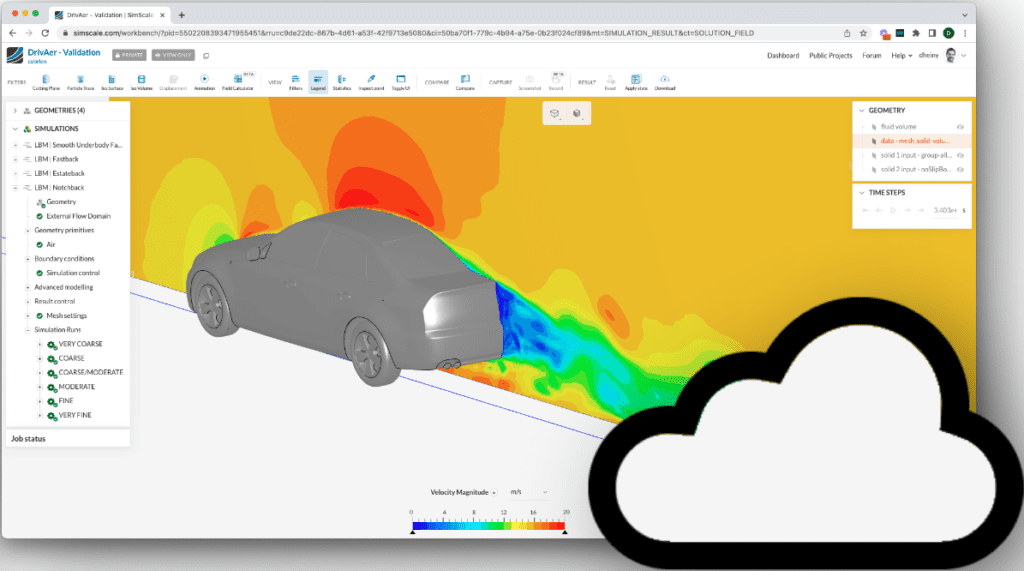

This is where digital solutions like engineering simulation can play a significant role. And by leveraging the power of cloud computing and AI, the impact of cloud-based simulation on innovation and engineering efficiency can be significant. But let us first take a look at the automotive industry today and find out what trends and technologies are driving the market today.

The Four Trends Driving the Industry: ACES

As we are stepping into a new age of technology led by AI, digitalization, and sustainability, the automotive industry is going through a major transformation. Industry leaders are venturing into new avenues of design and manufacture, incorporating cutting-edge software and digital solutions that can help them keep up with the competition and the ever-growing demand.

As a result, multiple trends have emerged, which not only stem from technological advancements but also consumer perception of and willingness to adopt these technologies. The Center of Automotive Research (CAR) calls these trends ACES, which is an acronym for autonomous, connected, electric, and shared vehicles. Although we have seen major developments in other application areas, such as Hydrogen vehicles (which we will cover in another article), the ACES trends seem to have taken the lead, according to industry experts.

“[ACES] will enable new mobility paradigms, new companies, and new business and revenue models that have the potential to alter the way consumers interact with vehicles.”

Center of Automotive Research (CAR)

1. Autonomous Driving

Autonomous vehicle (AV) technology has emerged as a transformative force in the automotive industry, driven by advancements in AI, sensors, and connectivity. Not only will AV change the way cars navigate the roads, but it will also have a significant impact on the design, manufacture, and supply of components and systems.

“15% of new cars sold in 2030 could be fully autonomous.”

McKinsey & Co. [2]

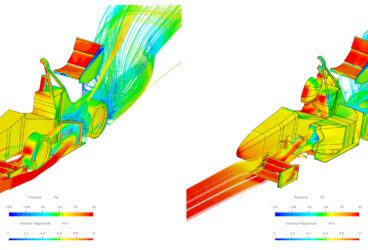

AV will result in a shift from traditional automotive components to advanced sensor systems, computing platforms, and communication devices, which would primarily impact Tier 1 suppliers. As vehicles become more autonomous, the demand for sophisticated sensors, such as LiDAR, radar, and cameras rises exponentially. Tier 1 suppliers need to adapt their product portfolios and the manner by which they design their products to meet the evolving needs of OEMs. For this, they must find solutions that would enhance their engineering efficiency and boost their innovation.

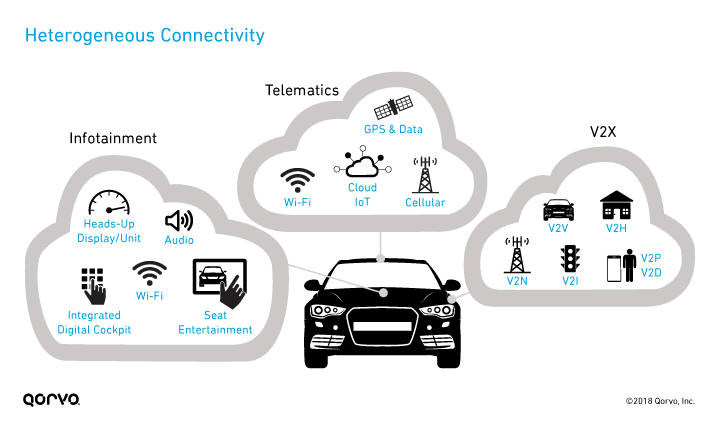

2. Connectivity

The advent of vehicle connectivity has made it possible to process data from a wide range of sensors located at the edge and in the cloud. As a result, the volume of data that connected cars are expected to generate will increase as autonomous driving increases.

“Data traffic from connected vehicles is expected to be over 1,000 times the present volume, exceeding 10 exabytes per month by 2025.”

T-Mobile [3]

As such, mobility will change as connectivity is further enabled, especially with the advent of machine learning (ML) and edge AI applications.

3. Electric Vehicles

EVs are arguably the most impactful and pivotal trends in the automotive industry today, marked by a departure from traditional internal combustion engines towards cleaner, sustainable alternatives. The electrification of vehicles is driven by a growing global emphasis on environmental sustainability and the need to reduce carbon emissions. As governments worldwide implement stringent emission standards, the automotive landscape is witnessing a surge in EV adoption.

“Over 55% of all new car sales could be fully electrified by 2030.”

PwC Autofacts [4]

With lower battery costs, increasingly available charging infrastructure, and growing consumer approval, EVs will continue to have a strong impetus in the market in the near future. This includes its hybrid, battery-electric, plug-in, and fuel-cell-powered vehicles. In order for automotive suppliers to succeed with EVs, they need to leverage partnerships, especially with service providers that are leading the technological landscape. They need to invest in solutions that enable them to accelerate their innovation and production.

4. Shared Mobility

Motivated by efficiency, sustainability, and social inclusivity, shared mobility has begun to take shape over recent years. Although consumers by large still want to hold on to their private vehicles, many are gradually embracing the concept of shared mobility. In other words, mobility becomes an on-demand service in the form of car sharing, ride sharing, or mobility as a service (MaaS).

“40% of consumers expect to commute using shared mobility services in the next 5-10 years.”

Ericsson [5]

This not only is economically viable, especially with the introduction of autonomous vehicles, but it could also lead consumers to become consistently aware of technological advances, given the short life cycles of shared mobility solutions. This would put pressure on OEMs and, in turn, Tier 1 suppliers to augment the upgradability of the vehicles and their technological features.

Race of the Decade: How to Lead the Auto Supply Market

With EVs, AVs, connectivity, and shared mobility driving the automotive industry, suppliers are required to innovate faster while increasing engineering efficiency in order to maintain their competitive edge.

To achieve both requirements, suppliers and OEMs need to transform their engineering workflow, starting as early as the design stage. This can happen by fully digitalizing the design and engineering system and enabling teams to collaborate quickly through multiple design iterations. As such, teams should leverage simulation as a decision-making catalyst that underpins the whole design process.

Here at SimScale, we believe simulating early and broad can transform the product design process as it would inform design decisions efficiently rather than merely validate designs at the end of every cycle.

“The key advantage of using SimScale for us is to extract fast design insights at the early stages. We can then arrive at a final design faster and have more confidence when moving to the physical prototyping stage.”

Massimo Savi, ITW

First to Cloud-Native Simulation Wins

In order to accelerate new product introduction while lifting engineering efficiency on legacy products, OEMs and automotive suppliers must iterate through design runs more quickly and efficiently. For that, they need to incorporate digital solutions that can minimize costs and maximize the speed of sound decision-making. Therefore, those who adopt cloud-native engineering simulation will be one step ahead of the competition.

“Companies that invest 25% of their R&D budget in software applications are rewarded with strong growth.”

PwC Autofacts [4]

With SimScale’s next-generation simulation that leverages the power of cloud computing and AI, automotive suppliers can circumvent the long lead times and siloed approach of legacy simulation. They can employ aggressive simulation by utilizing parallel testing, which can reduce lead time from weeks to minutes.

Contact us below for more information on how to adopt cloud-native simulation in your workflow, or visit SimScale’s Product Overview section to have a look for yourself.

References

- Proff, H. et al. (2023). 2023 Global Automotive Consumer Study, Deloitte.

- Gao, V. P. et al. (2016). Automotive revolution – perspective towards 2030, McKinsey & Co.

- T-Mobile for Business (2021). Meeting The Growing Demand For Connected Car Data, Forbes.

- Kuhnert, F. & Stürmer, C. (2018). Five trends transforming the Automotive Industry, PwC.

- Laya, A. & Vyas, N. (2021). Shared mobility: Why ‘they’ should all be sharing their cars, Ericsson.