At the center of today’s innovation and tomorrow’s product ideas lies engineering simulation. This behind-the-scenes tool has revolutionized how products are designed, tested, and manufactured. And now, with cloud computing in the mix, cloud-native simulation has become the go-to CAE solution for engineers and designers.

Evidently, this is reflected in the market. The global simulation market has grown massively over recent years thanks to its facilitating engineering organizations to increase top-line growth and simultaneously drive bottom-line savings, all while improving the sustainability of products and processes. In fact, several reports have shown that analysts expect a market rise of 13% CAGR over the next five years, closing in on the USD 30 billion mark by the end of the decade [1-3]. Particularly, the cloud simulation segment has shown explosive growth and is estimated to drive the highest growth in the coming years. This is mainly because cloud-native simulation allows the use of engineering simulation earlier in the design process and broader across physics while reducing the cost and technology footprint.

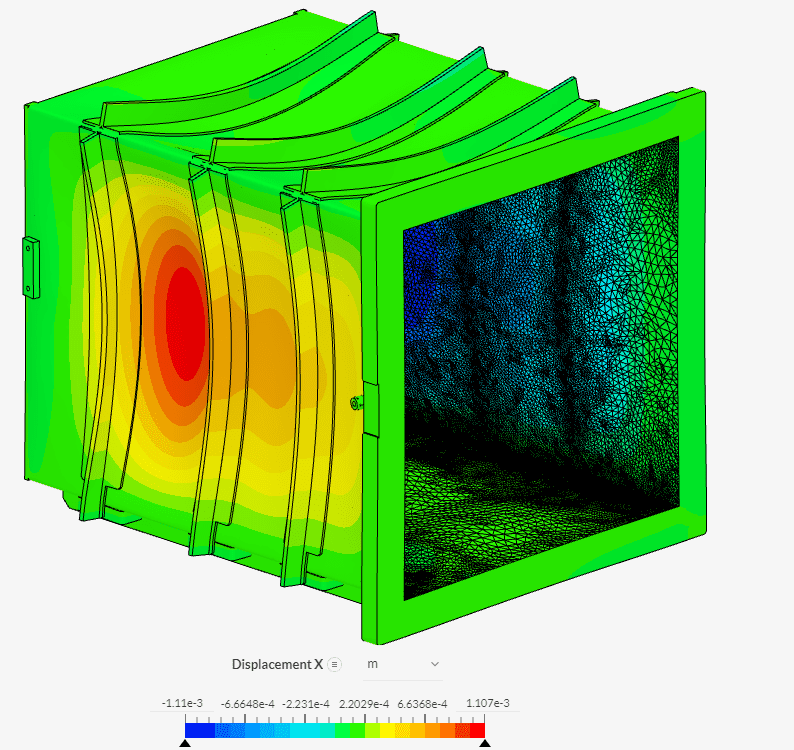

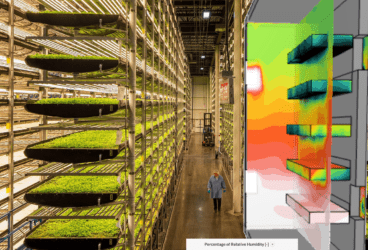

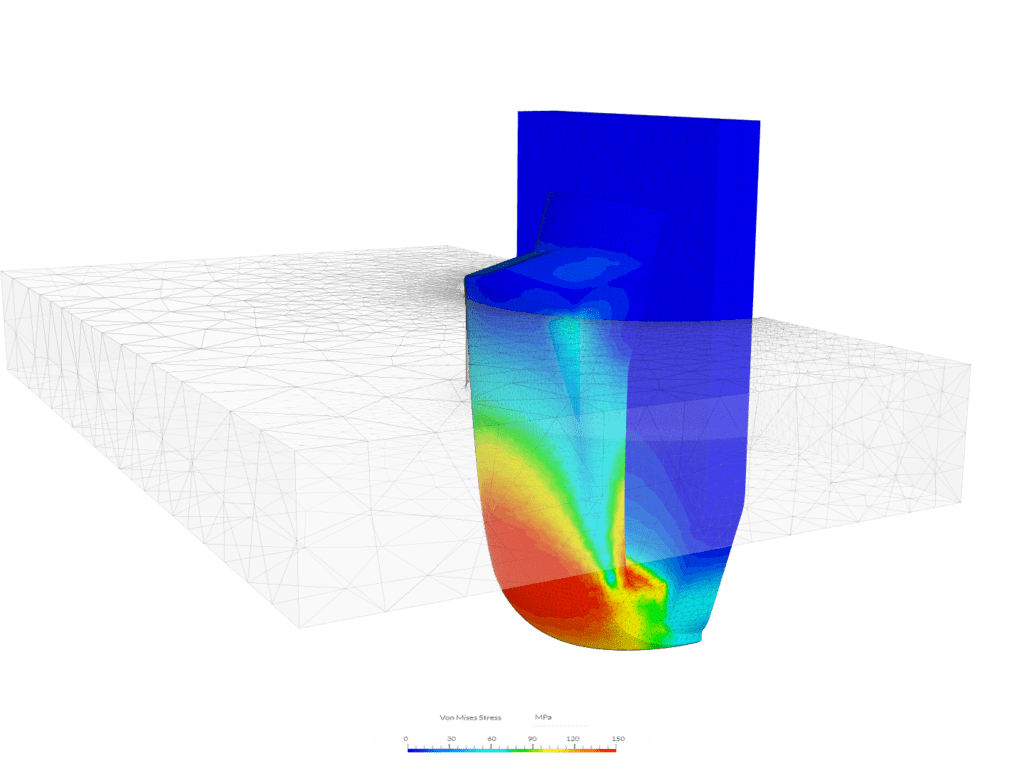

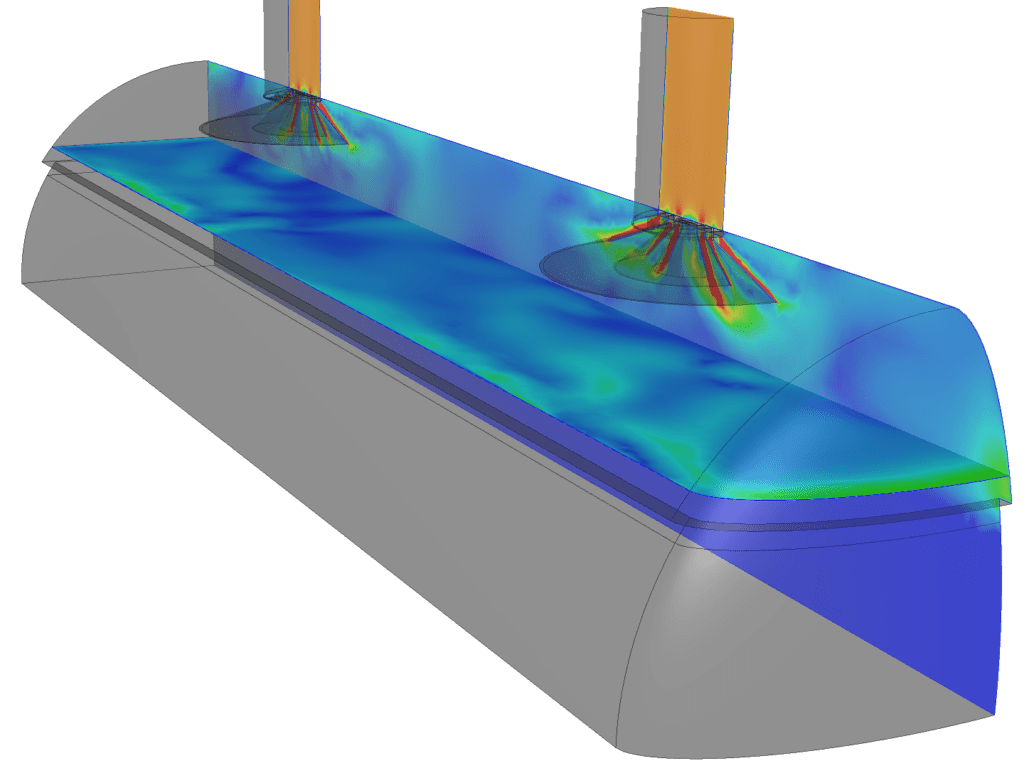

From CFD analyses of aerodynamics, turbomachinery, and urban microclimates to FEA simulations of structural mechanics in automotive and consumer products, all the way to thermal analyses for indoor environments and electronics cooling, the applications for engineering simulation are numerous and can involve multiple physics. In this article, we dive into cloud simulation and CAE and find out how it strategically impacts business growth and helps optimize financial resources, enabling sustainable growth and profitability while minimizing risks. We explore in numbers how various companies from different industries have benefited from SimScale’s cloud-native simulation platform and how you can, too.

Accelerating Innovation with Cloud-Native Simulation

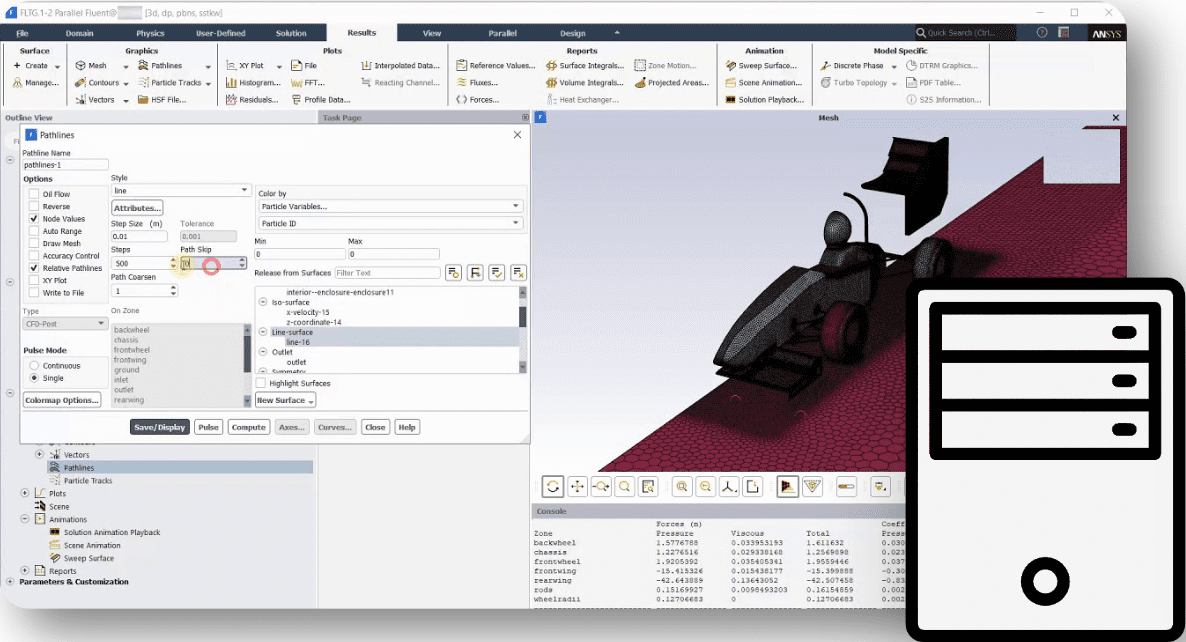

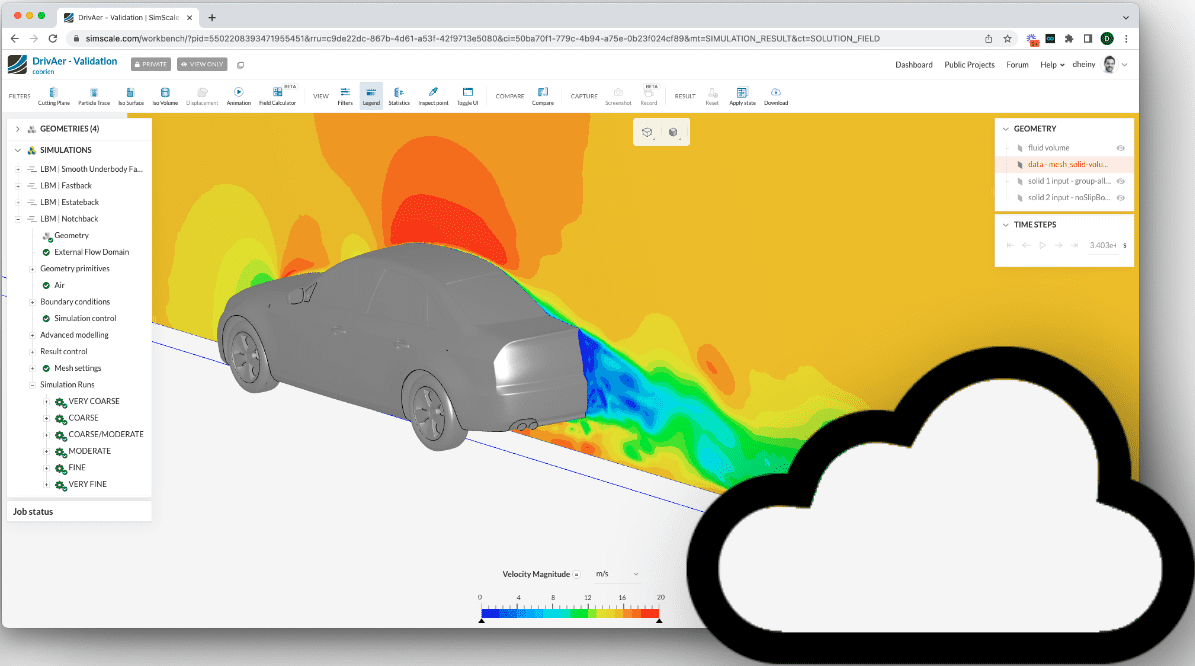

SimScale’s cloud-native simulation harnesses the power of cloud computing to execute complex engineering simulations, modeling scenarios, and data analysis with unprecedented speed and efficiency. This approach has profound implications for businesses, particularly in the engineering domain, where traditionally time-intensive and resource-demanding processes have been a barrier to rapid innovation.

In essence, it provides engineers with rapid access to the cloud’s high-performance computing resources, enabling them to conduct multiple simulations simultaneously and iterate designs swiftly. This accelerates the development of new products, allowing for the exploration of a broader range of design possibilities and advanced features.

Not only does cloud-native simulation drive innovation, but it also ensures prudent and strategic financial management of the R&D process, as it delivers quantifiable financial benefits that arise from reduced physical testing, optimized resource utilization, faster time-to-market, and more. By reducing the reliance on physical prototypes and enabling virtual testing, cloud simulation promotes cost-effective experimentation, leading to breakthroughs in product performance and functionality. Additionally, the data-driven insights derived from simulations enable informed decision-making, further fueling innovation and pushing the boundaries of what’s possible in engineering and manufacturing.

Fundamentally, cloud-native simulation maximizes business value by enabling earlier, broader, and more intense simulation use while having no IT/Capex footprint. The table below clarifies how cloud-native simulation compares to traditional computer-aided engineering (CAE) use and mere physical testing without simulation.

| No Simulation | Traditional Simulation | Cloud-Native Simulation | |

|---|---|---|---|

|  |  | |

| Simulation Use | Physical testing only | Late-stage validation | Continuous |

| Simulation Users | None | Few CAE experts | Designers, Engineers, Experts |

| Possible Design Space | Narrow | Broad | Significantly broad |

| R&D Cycle Time | Long | Short | Minimal |

| IT/Capex Footprint | High | Significant | None |

The impact of SimScale’s cloud simulation can be realized on two levels: top-line growth and bottom-line savings. In the following sections, we look deeper into each level and explore case studies of companies from industries like automotive, AEC, electronics, energy, and others that have already benefited substantially from cloud simulation.

Top-Line Growth with Cloud-Native Simulation

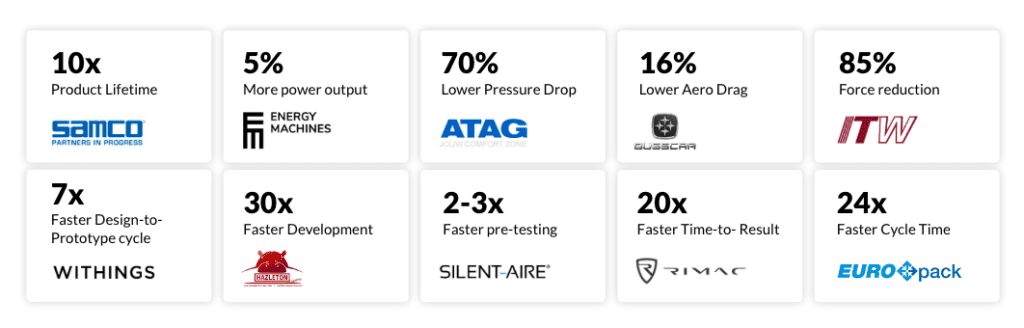

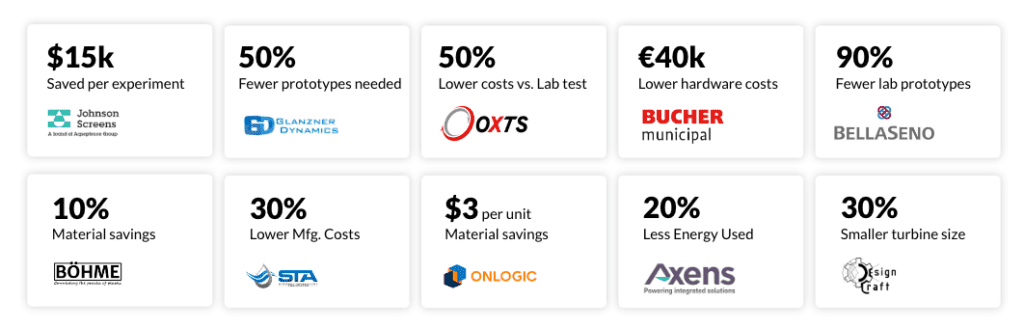

SimScale supports business revenue growth by reinforcing strategic approaches to accelerating innovation. This can be exemplified by boosting product performance and expediting time-to-market. Figure 2 displays the quantifiable benefits of many SimScale customers that have boosted their top-line growth with cloud-native simulation. Let’s dig deeper and learn more about some of these case studies.

Higher Product Performance

Using cloud simulation, engineers and designers can conduct complex simulations that were once computationally prohibitive, which enables them to develop and validate advanced product features more efficiently to reach higher product performance. This can result in higher end-customer satisfaction and enables companies to push design boundaries, innovate faster, and gain a competitive edge in the marketplace.

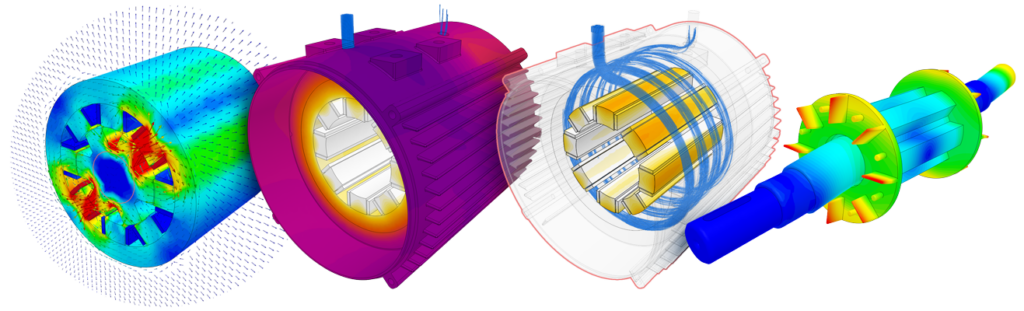

SimScale enables broad simulation across different physics and applications with a full-stack simulation technology that empowers users to boost their products’ performance and validate faster and better using scalable cloud-computing power. With its powerful solvers for fluid dynamics, structural mechanics, thermal analysis, and electromagnetics, SimScale allows for integrated, complex, and large-scale simulations, generating a wealth of data that reinforce decision-making and product development strategies, leading to better opportunities for establishing a stronger presence in the market.

One example is ITW, a global design and engineering firm and a leading global supplier of auto parts. Using SimScale, ITW engineers conducted nonlinear static simulation and analysis to accelerate the development of plastic automotive fastening components, allowing them to minimize the insertion force of their fasteners by up to 85% while saving 10% of their R&D costs.

Another example is Samco, a semiconductor and materials company out of Japan. One of Samco’s main principles is providing durable and highly reliable equipment, and that’s why they opted to use SimScale’s CFD, mechanical, and thermal simulation capabilities. With its ease of use and low cost compared to on-premises-based solutions, SimScale was an attractive choice for Samco’s design team, especially being first-time users. Using SimScale early in the design phase of a vacuum chamber enabled them to make small but rather effective design modifications, increasing their product lifetime by no less than ten times to exceed a million operating cycles.

Faster Time-to-Market

Shorter development cycles facilitated by cloud simulation can lead to earlier product launches, capturing market opportunities ahead of competitors and increasing revenue streams. In fact, one of the most impactful aspects of SimScale’s cloud-native simulation is parallel simulations. Engineers and designers alike can conduct multiple simulations in parallel with no limit on simulation size, number of simulations, or storage. This not only accelerates time-to-market but also increases scalability and eliminates the need for multiple steps and hand-offs between teams.

With SimScale, you can shorten your design cycle time and fix design issues earlier by benefiting from parallel simulations, faster data processing, rapid prototyping, easier collaboration and accessibility, and reduced administrative overhead. Simply, any authorized team member can access the simulation projects anytime, anywhere, directly in their web browser, and run parallel simulations that can cut design cycles from weeks to days and even minutes.

This is exactly what Withings was able to do using SimScale. This consumer electronics company leveraged the SimScale platform to conduct structural analysis of its health monitoring equipment. Running multiple simulations in parallel allowed them to reduce their design-to-prototype cycles by no less than seven times, enabling them to test new designs and push their products to market much faster.

“By using the novel mechanical simulation based in the cloud offered by SimScale, we engineers at Withings have been able to reduce our design-to-prototype cycles from weeks to days. This tool widens our possibilities to test new designs, materials, and techniques and anticipate possible failures, as well as gains in mechanical performance within a few clicks.”

Victor Pimenta – Mechanical Engineer at Withings based in Paris, France

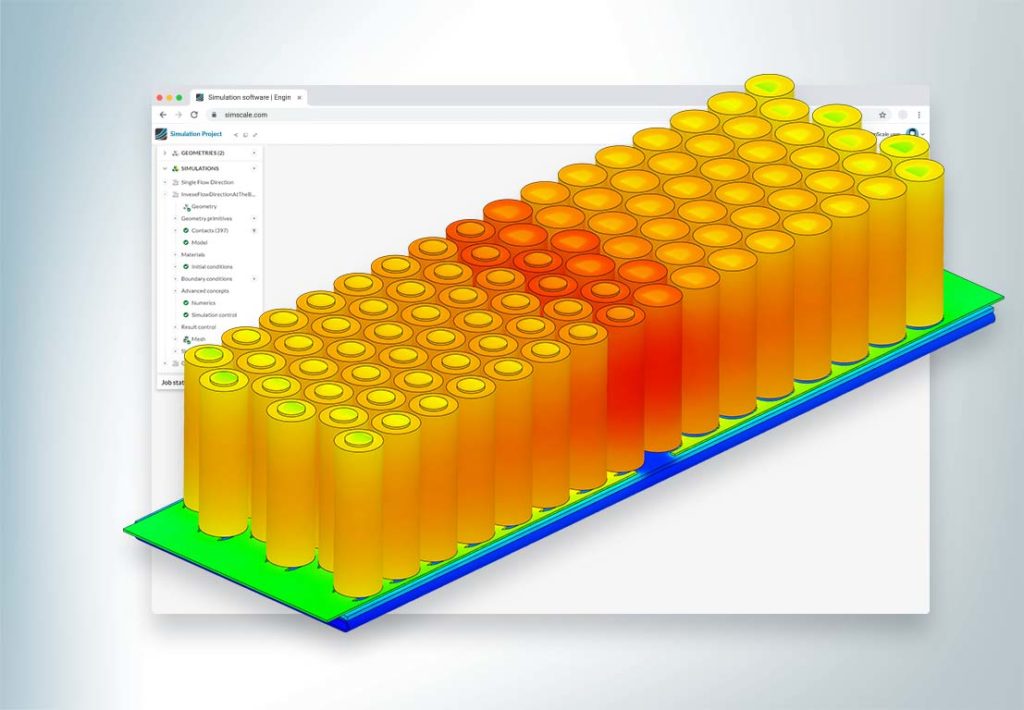

Another company that shortened its design process significantly is Rimac. This visionary electric car manufacturer made use of SimScale’s thermal simulation tool to study the cooling of their battery pack. They easily managed to conduct 30 simulations in parallel, allowing them to save up to 96% in time savings and run ten different parameter variations. This shortened their time-to-result by 20x.

Bottom-Line Savings with Cloud-Native Simulation

SimScale’s cloud-native simulation enables companies to ensure substantial savings on operational costs, improve profit margins, and increase net income by lowering R&D and engineering costs and minimizing costs of goods sold (COGS). These cost-cutting measures and efficiency improvements can have a significant bottom-line impact, enabling companies to enhance their financial health and profitability. Figure 6 showcases how SimScale customers have leveraged cloud simulation to improve their bottom-line savings.

Lower Engineering and R&D Costs

With SimScale, you can replace a large chunk of your physical prototyping efforts, enabling you to reduce the costs of prototyping and hardware significantly. In some cases, you wouldn’t need to run any physical testing until the end of your testing process for final validation because simulation can provide accurate data and results that enable you to run design iterations faster and, evidently, at lower costs. This reduces your R&D turnover and supports the company’s strategic and financial efforts, not to mention the reduction of costs associated with compliance and safety standards.

Johnson Screens, a global supplier of industrial products in the AEC industry, has leveraged SimScale’s cloud-native CFD tool to conduct airflow analyses instead of conducting physical experimentation. As a result, they were able to save up to $15,000 in engineering costs and months of preparation per experiment.

“To get the same results with a physical test, it would take us months and would cost anywhere from $7k to $15k, even for this project, which is actually very small in scope. With SimScale, we could just run a virtual test at the office, which took only 18 minutes.”

Daryn Bertelson – CAE Engineer at Johnson Screens – Aqseptence Group

Lower COGS and Product Costs

Another bottom-line advantage of cloud simulation is the minimization of COGS and costs associated with materials, energy consumption, and warranties. With virtual prototyping, the need for physical prototypes is reduced, saving time, energy, and material costs during the design phase.

One example is Kichler, a residential lighting supplier out of the US. Kichler has opted to adopt an entirely cloud-based engineering software stack, which has resulted in faster product innovation and lower hardware and software costs. Using SimScale, they managed to entirely eliminate prototyping costs and save significantly on material costs.

“The total material cost saving was 44%. We eliminated testing and prototype costs on this project entirely. It usually takes 1-3 weeks of prototyping time and another 1-3 weeks for all the testing normally done. Overall this project was successful and it helped achieve our goal of reducing cost and keeping within the project timeline.”

Josh Levine – Lead Engineer in Value Engineering Department at Kichler Lighting

Another one is Axens, a solution provider for the conversion of oil and biomass to cleaner fuels. By embracing cloud-native simulation with SimScale, they were able to optimize their design and save up to 20% in energy consumption. They also saved about €27,000 in external simulation costs by opting to do the simulation work in-house rather than outsourcing it.

Sustainable Product Growth with Robust R&D Savings

Cloud simulation stands as a transformative force in engineering and manufacturing, offering the promise of accelerated time-to-market, heightened innovation, and cost-efficient operations. By harnessing the power of the cloud with SimScale, organizations can navigate the complex landscape of product development with greater agility, achieving top-line growth through rapid innovation while simultaneously bolstering bottom-line savings through optimized processes and resource utilization.

This dynamic synergy positions companies not only for immediate success but also for sustained, long-term growth, ensuring their competitiveness in an ever-evolving marketplace while maintaining financial prudence and operational efficiency.

References