Picture yourself at a motorsports event with the deafening roar of engines and the thrill of high-speed competition all around. In the midst of this excitement, you notice a breathtaking moment of driving finesse as one car expertly tucks in behind another. This phenomenon isn’t just a spectacle; it’s the art of aerodynamic drafting, a critical strategy in motorsports and racing that harnesses the laws of physics to reduce drag, enhance speed, and seize victory on the track.

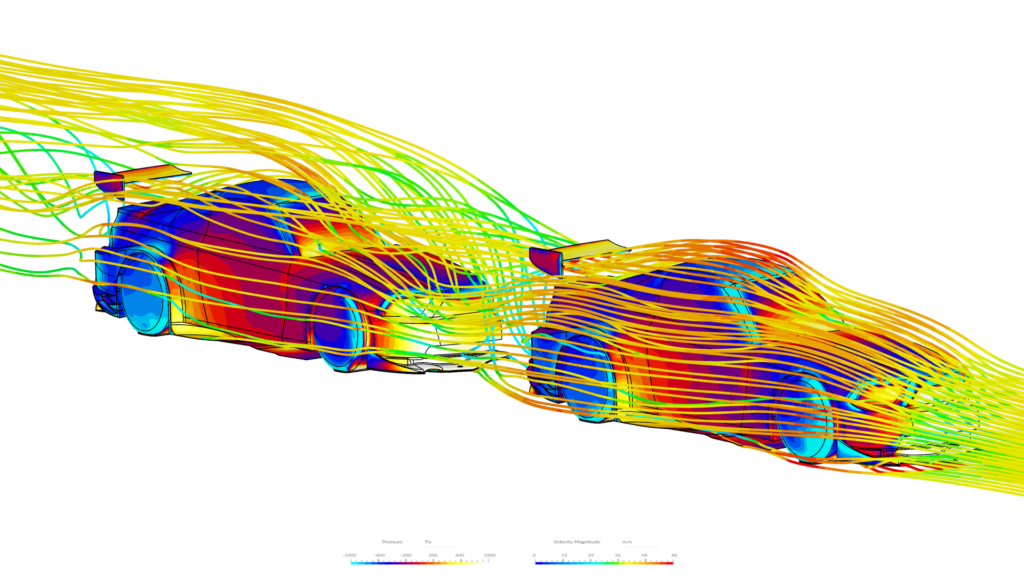

In this article, we will delve into the intricacies of drafting in racing, shedding light on how it works and the speeds at which it is most effective. We will also highlight the effects via a small CFD study using the SimScale simulation platform to visualize and capture the effects at different trailing distances.

What is Drafting in Racing?

Drafting refers to a strategic racing technique where a vehicle closely follows behind another, taking advantage of reduced air resistance or drag created by the lead vehicle. This aerodynamic phenomenon allows the trailing vehicle to experience a decrease in wind resistance, enabling it to achieve higher speeds or improve fuel efficiency compared to running independently.

Drafting is also interchangeably referred to as slipstreaming. Effective drafting requires a delicate balance between proximity to the lead vehicle and maintaining control, as getting too close can result in turbulent air and compromise stability.

How Does Drafting Work?

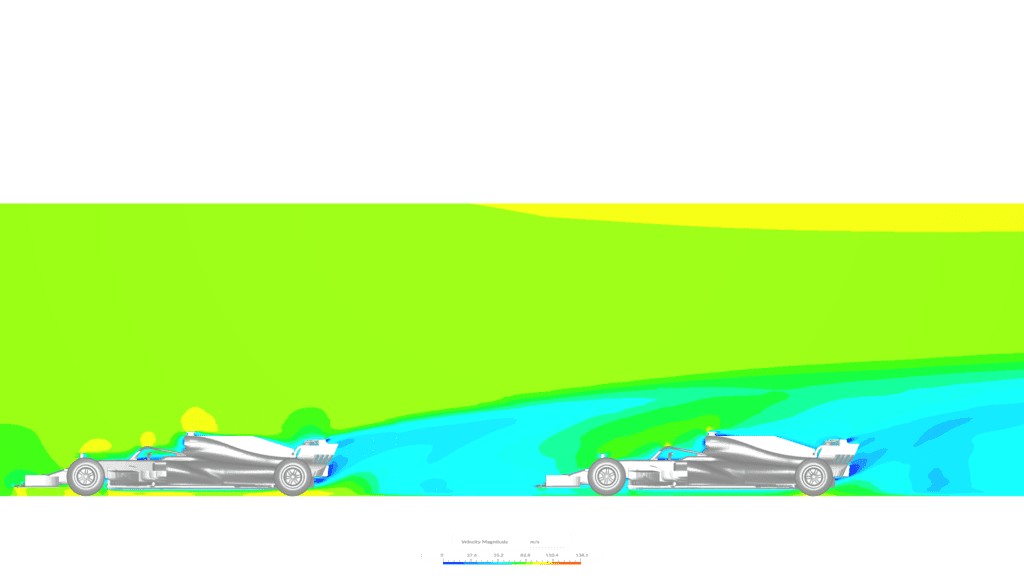

Drafting exploits a key principle of viscous, bluff-body fluid dynamics called “Boundary Layer Separation.” This phenomenon occurs when the airflow over an object loses its ability to follow the contour of the object’s surface and separates away from it, creating a turbulent and chaotic wake. This turbulent wake leads to reduced pressure or a vacuum region on the rear of the vehicle, creating a drag force that acts against the vehicle’s motion and necessitates additional energy to overcome. The net effect is a reduction in fuel (or electrical energy) efficiency or, in the case of a race car, a reduction in top speed.

When a following vehicle slips into this turbulent wake, its nose augments this wake, and the tandem vehicles will start to behave more like a longer, single aerodynamic body. Depending on the distance between the vehicles, the wake of the first car can be nearly eliminated. The corresponding pressure changes reduce the drag force on both vehicles compared to when traveling alone (raised rear pressure on the lead vehicle and reduced nose pressure on the trailing vehicle).

Thus, the overall convoy experiences significantly reduced air resistance, enabling it to achieve higher top speeds and more fuel efficiency with the same power output. Adding more cars into the drafting situation (as is typical at the Indianapolis 500 or on a NASCAR superspeedway, such as Daytona or Talladega) can further amplify the effect for the whole platoon. Also, drafting can be used by a trailing car to gain a short closing boost, which can be exploited to “slingshot” with momentum to overtake the lead car upon braking and corner entry, as is common in F1.

Other Effects of Drafting

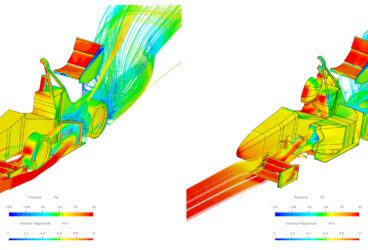

Dirty Air

Drafting can also cause a very pronounced aerodynamic force balance shift. When you hear a race car driver say that they were in “dirty air” or had the “air taken off of their nose,” they are referring to this shift in aerodynamic force balance. In essence, the center of pressure (or neutral moment point) moves front to rear (and possibly laterally and vertically) in response to the net change in pressure due to the draft. Too much of a shift rearward for the trailing car results in an understeer condition. The lead car may see the opposite effect, with a reduction in rear spoiler or underbody downforce, leading to an oversteer condition.

Overheating

Aerodynamic performance is not the only consequence of this “dirty air.” Getting adequate air cooling can often be a big issue for the following car. Drivers are constantly pushing hard and putting mechanical components, like the engine and brakes, to their thermal limits. When the total pressure (or ability to do work) of the air is greatly reduced to the trailing car, it starts to affect all of the cooling systems, which are designed for “clean” airflow; the radiators would not be able to work sufficiently, the airflow going through the brake ducts would be insufficient, and EV battery cooling would be suboptimal, etc. All of that causes overheating, and the drivers have to generally back off to manage those systems.

At What Speed Does Drafting Work?

The effectiveness of drafting hinges on multiple factors, including the overall velocity of both the lead and trailing vehicles, the spacing between them, and the shape of the vehicles involved. Drafting is most potent at higher speeds, generally exceeding 50 mph (80 km/h). At these velocities, the aerodynamic forces become more prominent, and the advantages of drafting become more pronounced.

Let’s take a closer look at the drag force equation below. Here, we can see that drag is proportional to the velocity squared, so a pair of race cars traveling 200 mph (~ 320 km/h) see 16x more drag than one at 50 mph (80 km/h) highway speeds. This greatly magnifies the drag change due to drafting.

$$ D = \frac{1}{2} \rho V^2 C_D A $$

where:

- \(D\) is the drag force acting on the car,

- \(\rho\) is the air density,

- \(V\) is the relative velocity between the vehicle and air,

- \(C_D\) is the drag coefficient,

- \(A\) is the reference surface area of the vehicle.

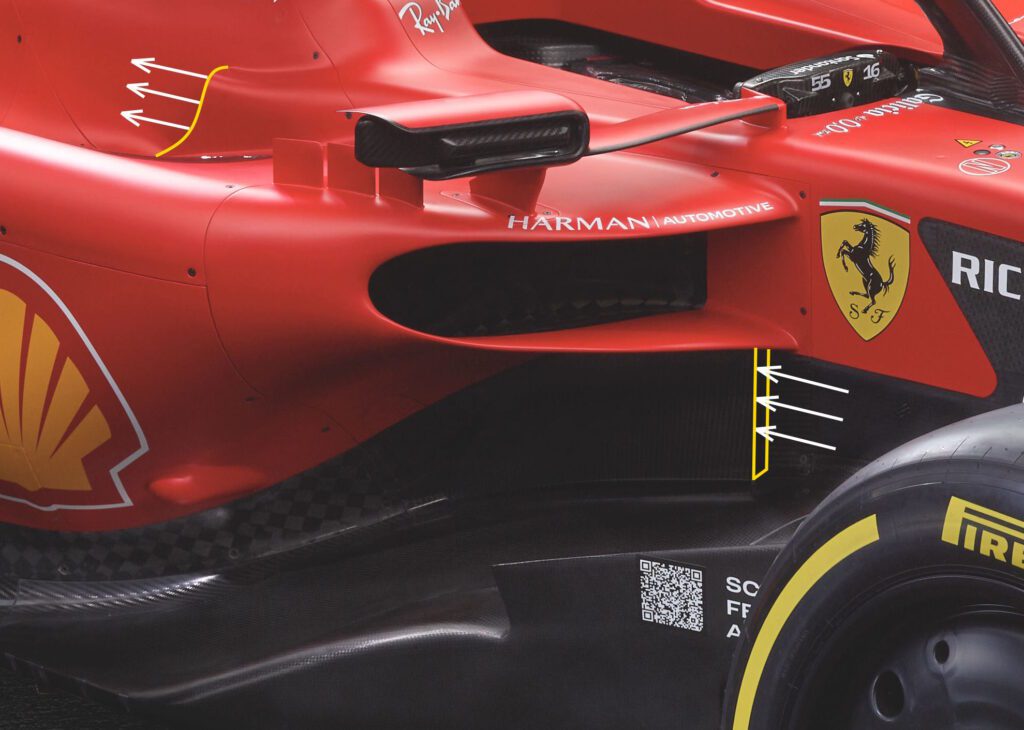

The overall aerodynamic shape of the vehicles and any aerodynamic devices (splitter, spoiler, wings, etc.) also greatly affect their drafting ability. Race vehicles can often be very dependent on the performance of these discrete aero components, so augmenting the airflow they feel can have an abrupt and often undesirable effect on the handling balance. This is especially true when cars are cornering and grip-limited. Here, you will often hear the drivers complain about the ‘dirty air’. Motorsports-sanctioning bodies are always exploring aerodynamic packages and overall car designs to limit this sensitivity, as it hampers competition and overtaking.

In addition to the vehicle shape and features, the ground clearance and underbody design elements (such as the diffuser) are also critical drivers of drafting performance. The low pressure suction produced by the underfloor is very sensitive to the airflow ingested and expelled. When a car is trailing another in the draft, the lead car effectively uses up the energy of the oncoming air and leaves much less to drive the underfloor performance of the trail car. Again, this can have detrimental effects on the handling balance and reduce the maximum grip the trailing car has available when cornering.

Simulation Analysis: Analyzing Aerodynamic Drafting Using CFD

To gain deeper insights into the intricate dynamics of drafting, engineers have turned to computational fluid dynamics (CFD) simulations, usually instead of wind tunnel experiments. This choice is often driven by the high costs of wind tunnels, but in this case, the overall physical size limitations of most wind tunnels prohibit multi-car testing.

CFD provides a platform to accurately predict and analyze how tandem cars will behave as they approach one another. A map of various relative positions can be explored to understand the handling effects, and steps can be taken to optimize drafting performance. Furthermore, engineers can understand why these changes are happening by visualizing the airflow, which would accelerate the cars’ development and inform design changes. This powerful tool empowers engineers and designers to foresee the performance of their designs under different conditions and optimize them before hitting the track.

Aerodynamic Drafting in SimScale

On the SimScale platform, there are two different CFD modules that could be employed to simulate external vehicle aerodynamics and assess drafting performance. The Incompressible module utilizes the computationally efficient and practical finite volume approach (FVM), using the Reynolds Averaged Navier-Stokes (RANS) k-w SST turbulence model, which is prevalent in industry. The other approach leverages the advanced Incompressible Lattice Boltzmann Method (LBM), which can quickly solve high-fidelity, transient turbulence utilizing the power of GPUs.

Generally, LBM is the better option with regard to accuracy (particularly in the rear wake), scalability, and geometry robustness. Nowadays, DES and IDDES turbulence modeling (as is deployed in the LBM solver) is considered state-of-the-practice for accurate external vehicle aerodynamics simulations. However, if a quick early screening is all that is required, a simplified model using the Incompressible RANS approach still has merit.

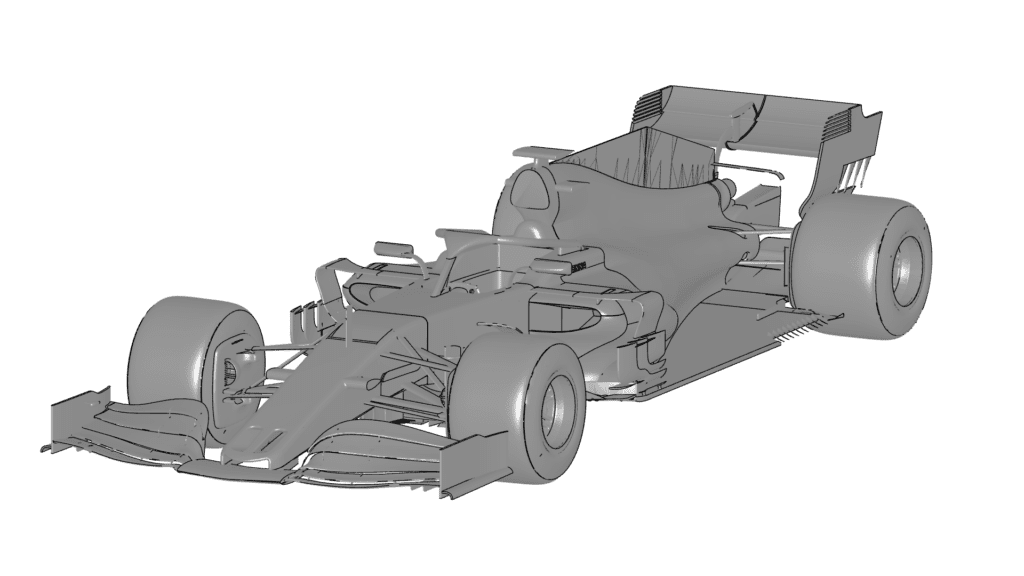

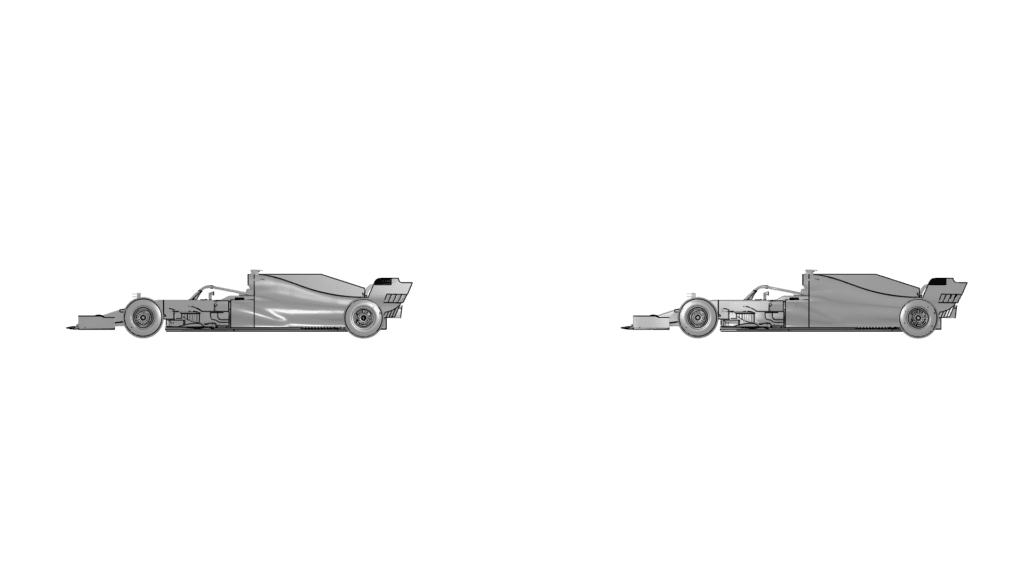

A drafting study was conducted in SimScale using the geometry from the 2019 Formula 1 regulations, as shown in Figure 5. This geometry was imported from a dirty .stl surface mesh directly into the platform. The poor quality of this starting geometry is not an issue for the LBM module, as it is able to handle non-manifold surface mesh geometries in this format.

A single-car simulation was first conducted to get baseline values for drag, lift (downforce), and lift balance coefficients and a corresponding surface pressure plot. This “virtual wind tunnel” CFD simulation was conducted at 180 mph (~ 290 km/h) and assumed a rolling road and spinning tires via a rotational wall velocity. Force coefficients are summarized in Table 1 below.

| Case | \(C_L\) | \(C_D\) | Front Balance | Rear Balance | \(\Delta C_L\) | \(\Delta C_D\) | \(\Delta Front\) |

|---|---|---|---|---|---|---|---|

| Single Car | -0.945 | 0.805 | 13.61% | 86.39% | — | — | — |

| Drafting Car 1 | -0.871 | 0.738 | 13.59% | 86.41% | 0.074 | -0.066 | -0.02% |

| Drafting Car 2 | -0.444 | 0.625 | 19.64% | 80.36% | 0.501 | -0.180 | 6.03% |

The vehicle was shown to have a relatively high drag coefficient (\(C_D\)) of 0.805, which is expected for a race vehicle. The downforce was much lower than would be expected for an F1 racer, with a \(C_L\) of only -0.945. Also, the aerodynamic balance is heavily biased towards the rear, with a 14 to 86% front/rear balance. These differences are mainly driven by inaccuracies in the CAD model, particularly around the aero devices, ride heights, and interior structures. This serves to highlight the sensitivity of aerodynamic design.

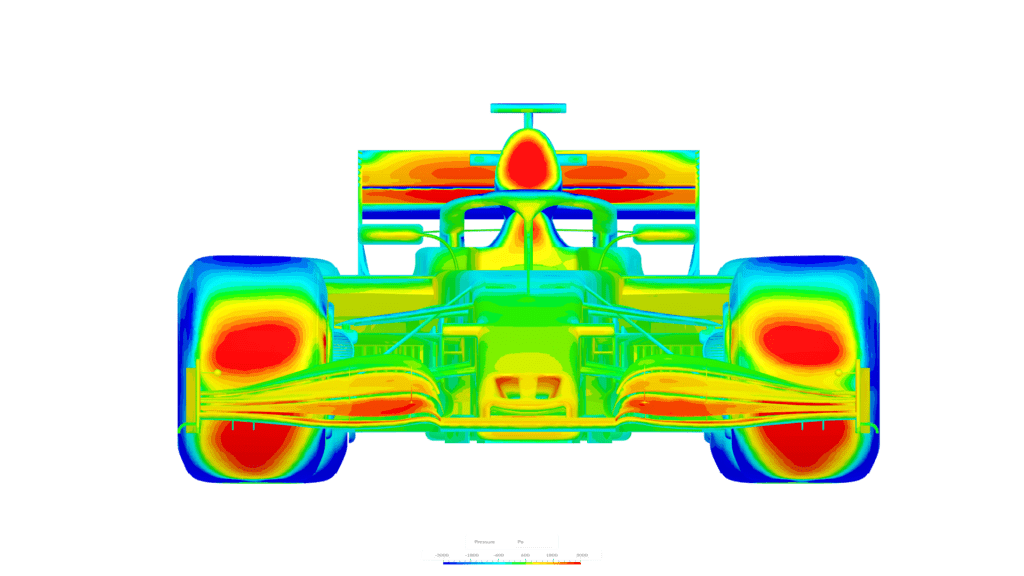

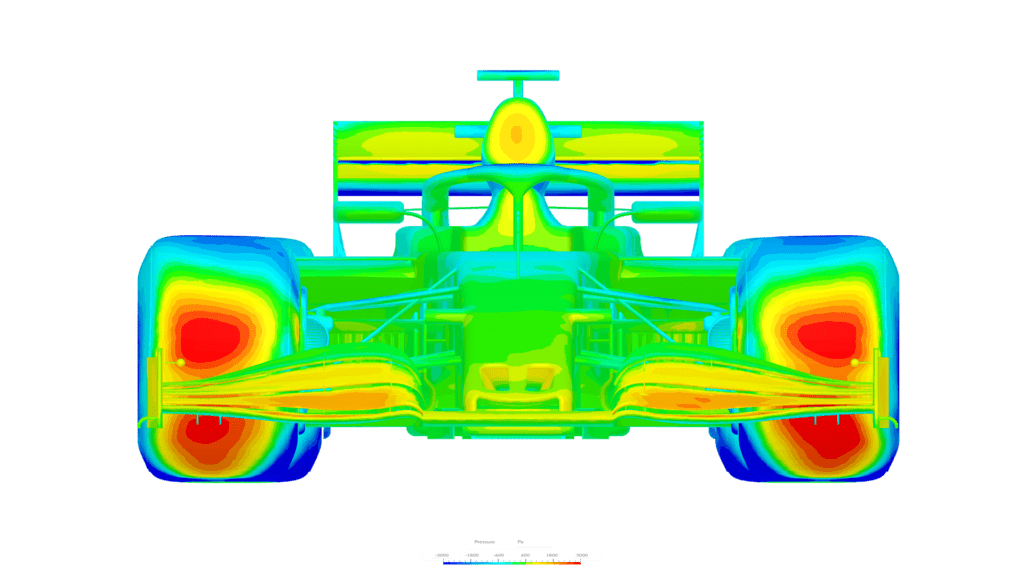

For this study, it is more interesting to explore the aero differences once an identical second car is introduced into the draft, at a trailing distance of 1 wheelbase (~ 3.5 m). This is shown in Figure 6. The tandem pair is still traveling at 180 mph (~ 290 km/h), so this would be akin to slipstreaming down a straightaway just prior to deciding to overtake under braking.

Here, we can assess the aerodynamic force and moment changes due to the drafting effect. In this scenario, the lead and trail cars see a -0.066 and -0.180 reduction in \(C_D\), respectively. This is a drastic drag reduction of more than 22% for the following car, compared to when traveling alone! When viewing the frontal surface pressure, it becomes apparent that the trail car will exhibit much less drag, as it sees much less overall static pressure to act against the forward motion. This is very evident on the wings, engine, duct inlets, and even the tires.

As a consequence of less activation of the aerodynamic devices (particularly the front and rear wings and the rear diffuser), the tandem cars experience an overall reduction in downforce. This is especially true for the trailing car, which sees its downforce cut down by more than half! It would be imperative for this driver to slip past the lead car and get into some fresh air under braking into the corner.

There is so much more that could be explored in this drafting CFD study, including the reduction in duct inlet flow, the effect of drafting distance, and the effects of stepping slightly out of the draft (just to name a few). You may try that for yourself and explore these effects by accessing, copying, and running this “F1 2019 Drafting Study” project in SimScale.

With its online CFD toolset, SimScale enables engineers and designers to easily simulate aerodynamic cases like this one early in the design process directly in their web browser without the hassle of hefty hardware and expensive prototyping. The scalable high-performance computing platform in SimScale enables automotive and motorsports aerodynamicists to quickly and easily conduct vehicle drafting CFD studies. Try it for yourself by clicking the “Start Simulating” button below.