Ductwork plays a crucial role when it comes to controlling the delivery and removal of air in both residential and industrial buildings.

In the past, simplified analytical models were used to predict the flow profile of a complete duct system. In contrast, nowadays fluid flow simulation (CFD) technology delivers three-dimensional insights into the whole flow field and takes into account all physical effects, as well as the full geometry of the object.

For this project, the engineers at Glanzner Dynamics used CFD simulation with SimScale to design a new exhaust pipe for a ventilation system. Their client thought that with the standard design, the airflow might produce high levels of noise due to flow vortices and turbulent fluctations. Therefore, a modified airflow pathway that reduced noise was needed. Glanzner Dynamics improved the design that would redirect the flow and slow it down as much as possible.

Sebastian Glanzner, the engineer responsible to perform the duct system optimization using SimScale CFD, designed the inner geometry of the HVAC duct with Onshape and simply imported it into SimScale. The automatic hex-dominant algorithm available in SimScale was then used to generate a mesh of 1 million volumes.

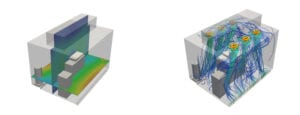

The inlet and outlet conditions were then defined and the simulation started. When Sebastian inspected the first result, especially the flow lines, he could directly see that the flow wasn’t optimal. Several vortices and an increase in flow velocity were identified.

Glanzner then proposed different design changes and ran multiple simulations in parallel with SimScale to assess which one would deliver the best airflow behaviour, with the most important parameter to not generate noise when the duct is working.

The CFD results showed that the best way to solve the problem was by inserting pipe segments in order to create a curve in the duct. This would then need to have an optimal shape as to refrain from accelerating the flow too much, as well as to avoid any kind of recirculation or vortice.

Finally, an air guide plate was also added to further prevent the creation of any vortice, and other simulations were carried out in parallel to find out the optimal angle for construction.

With SimScale we achieved results very quickly and were able to improve the design of the pipe in less than a working day! Running multiple simulations simultaneously helped us speed up the process, and we had more time to complete the CAD drawings.

Sebastian Glanzner

Founder and Engineer

Glanzner’s client was impressed by the results, and the improvement in the design delivered by Sebastian.

The simulations allowed further improvement of the design by increasing the diameter of the vertical pipe to slow down the flow even more.

“By visualizing the streamlines, we immediately had new ideas on how to optimize the design. Together with our customer, we were able to quickly improve the design and always make sure it was easy to manufacture. Without SimScale we probably wouldn’t have achieved the optimal design,” said Sebastian Glanzner.

Glanzner Dynamics will continue to use SimScale as its CAE provider and to take advantage of simulating on the cloud.

Sign up for SimScale

and start simulating now