Imagine a world where you are limited to food that is grown locally. Until the late 1800s—before the invention of the refrigerator truck—products couldn’t travel far before spoiling. Sophistication is an integral part of today’s transport refrigeration units, which are shipping over 36 million loads of refrigerated products annually, worldwide. To preserve perishable goods on the long haul, companies in the pharmaceutical, medical, and food industries are increasingly relying on the “cold chain”—a temperature-controlled logistical supply chain. To ensure that the cold chain is not interrupted, a reliable and secure insulated shipping box is indispensable.

Why You Should Care About Simulation

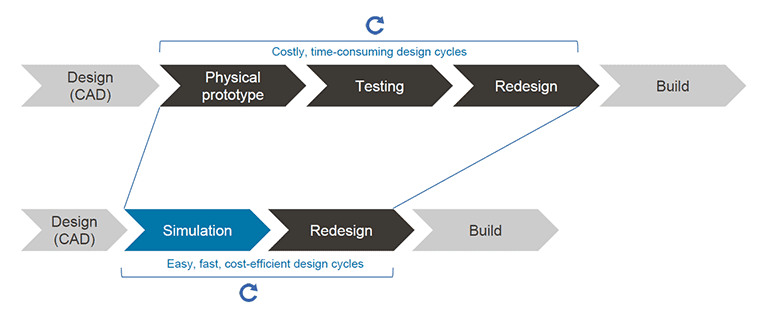

The design of any product is a highly complex process, and designing refrigeration units is a good example of that. In order to keep the cold chain uninterrupted, the insulated shipping box design needs to satisfy multiple objectives, requirements, and constraints. In the traditional design process, the only way to ensure the durability of such a product is to perform a high number of design iterations until all criteria are met. That means a high number of physical prototypes and a time-consuming and expensive physical testing process.

In addition to the number of design iterations, the stage at which design changes need to be implemented is equally important; the earlier in the overall process, the cheaper a design change can be realized. This drastically narrows down the scope of possible design changes, making only small, incremental design modifications possible at a later stage.

Of course, design iterations and physical testing cannot (and should not) be entirely eliminated from the product design process. However, with computer-aided engineering (CAE) the days, weeks or months of physical testing are replaced with hours or sometimes even minutes of a simulation run.

So how exactly would that apply to the engineering problem at hand? Here are a few compelling reasons to use simulation in the design of an insulated shipping box and predict its performance:

- Reduced development costs. Working with simulation software will help to significantly reduce the number of thermal tests that the packaging solution must undergo. This contributes to reducing the development costs by eliminating the need to manufacture a physical prototype while saving time and minimizing the environmental impact of laboratory testing, which consumes significant energy to simulate extreme hot and cold climatic conditions.

- Shorter time to market (TTM). Using a thermal simulation tool, engineers can reduce the number of design iterations and get the final packaging design to the market faster.

- Reduced risk. By simulating the efficiency of a packaging solution against logistic profiles not provided for initial qualification, designers can validate their design and increase its reliability.

Why SimScale?

The benefits listed above beg the question: Why aren’t all designers using simulation yet? Several barriers have been preventing a more widespread adoption of simulation tools by engineers and designers—and here’s how SimScale is aiming to challenge this status quo:

- Accessibility – Traditional software needs to be installed locally on a supercomputer, which just sits idly most of the time. With SimScale, all computations are done in the cloud—all you need is a standard web browser.

- Operating costs – Standard commercial tools are notoriously expensive. SimScale starts with a free Community Plan.

- Know-how – Most modern tools are designed for experts. To bridge the knowledge gap, SimScale offers a large public project library, free training, and live support chat.

The Engineering Problem: Insulated Shipping Box Design

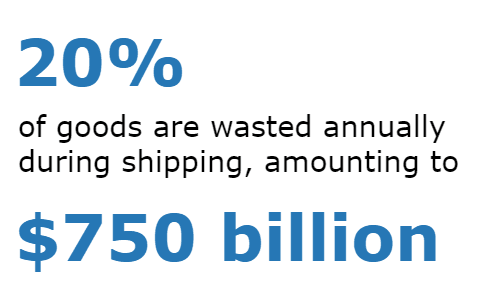

Cold chain systems are crucial to the growth of global trade in perishable products and the worldwide availability of food and health supplies. Global losses in the food industry due to poorly designed cold chain systems total more than $750 billion annually [3]. These losses primarily result from lack of proper facilities, improper food safety handling procedures, and insufficient training for that personnel working in the cold chain. The World Economic Forum lists food crises as fourth in its ranking of the top global risks for the next 10 years [1], and globally, billions of dollars are spent on improving agricultural processes to create higher food yields, but the fact that nearly half of all food never makes it to a consumer’s plate is largely ignored [2].

Let’s consider how simulation can help engineers tackle this problem by improving the insulated shipping box design for the cold chain.

Simulation Project

Project Overview

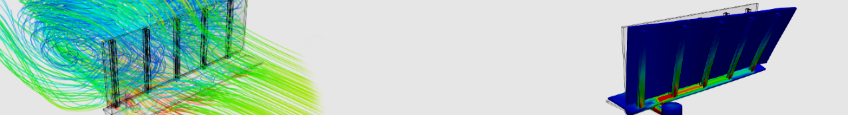

The purpose of this project is to perform an FEA (finite element analysis) thermal simulation on an insulated shipping box, with no conjugate heat transfer analysis necessary. We will also showcase the capabilities of SimScale with respect to heat transfer and thermal management.

The simulation project “Thermal Packaging for Cold Chain” is part of our Public Projects Library and is freely available to view, copy, and modify. A realistic insulated shipping box design is considered for the simulation, as shown in the figure below:

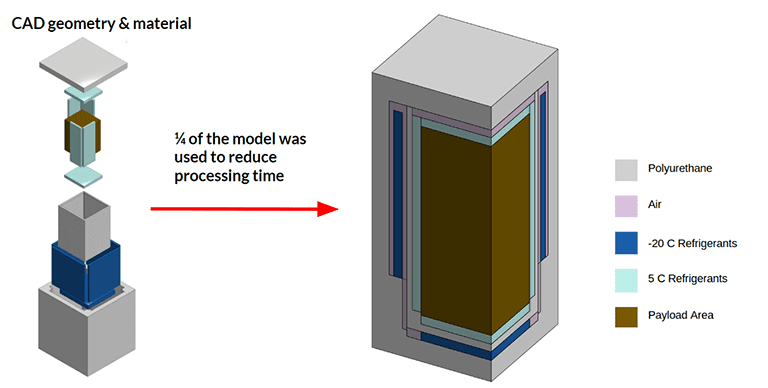

The CAD geometry was designed using the Onshape platform and consists of:

- Qty 1, molded PUR Base

- Qty 1, molded PUR Lid

- Qty 1, molded Inner Box

- Payload Area

- Qty 21, refrigerant bricks – 12 at 2 at 5°C and 9 at 8°C

In this insulated shipping box design, the temperature is passively controlled by pre-conditioned frozen (-20°C) and liquid (5°C) refrigerants in combination with an insulated polyurethane (PUR) foam container (with inner product box).

Simulation Setup

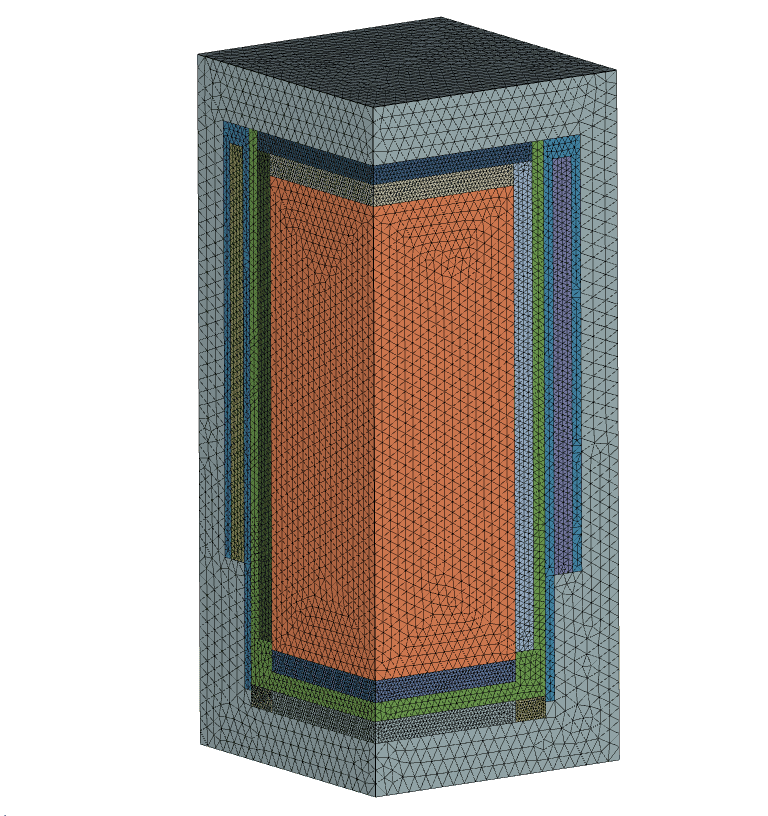

For the simulation setup, a nonlinear transient heat transfer analysis type is selected to compute the temperature distribution on the entire body. The detailed procedure for the setup is as follows:

- A tet-dominated meshing algorithm is used to mesh the entire geometry. An automatic operation was performed with a moderate mesh fineness.

- All the contacts were set as bonded contacts. For the actual model, we needed six pairs of contacts containing several faces, which were then grouped in topological entity sets.

- The material properties pertaining to the following components are shown in the table below with their corresponding density, specific heat, and conductivity.

| Component | Material | Density kg/m3 | Specific heat [J/(kg K)] | Conductivity [W/(m K)] |

| Base, lid and inner Bbx | PUR | 55.97 (adjusted) | 1500 | 0.025 |

| Refrigerant bricks at 5°C | Water | 941.14 | CSV file | CSV file |

| Refrigerant bricks at -20°C | Water | 619.41 | CSV file | CSV file |

| Payload | adjusted | 93.13 | 4200 | 0.0533 |

| Air | Air | 1.225 | 1005 | 0.0243 |

- The boundary condition is then set up with a convective heat flux applied to the outer surfaces of the insulated shipping box. The heat flux follows a temperature vs. time CSV file which corresponds to a 96-hour summer temperature profile.

Simulation Results

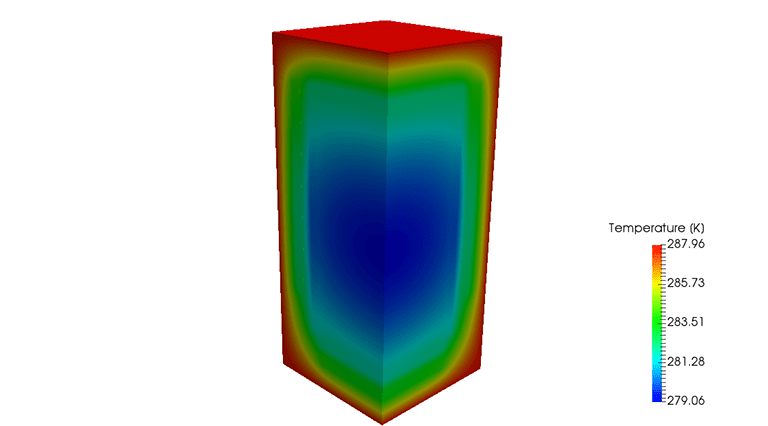

The simulation results are visualized below:

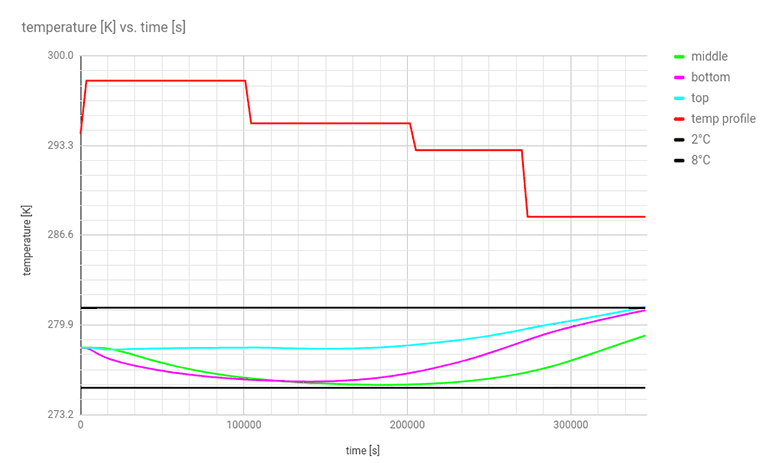

The change in temperature for three internal payload points:

From the simulation results, we can see that the temperature monitored inside the payload area remained between 2°C and 8°C, which was the main goal of this analysis.

If we analyze the final temperatures at each point, we see that they are really close, especially the top and bottom ones. This is due to the design. We have a -20°C refrigerant brick between the inner box and the base on the bottom. As the side -20°C refrigerants don’t reach the bottom of the inner box, it is important to have this -20°C brick as a barrier for the rising temperature from the bottom. We don’t need it on the top as the -20°C refrigerants surround the top side of the inner box.

The minimum and final values of the temperature are shown in the table below.

| Point Data | Min. temperature [K] | Temperature at the end [K] |

| Top | 278.02 | 281.19 |

| Middle | 275.37 | 279.06 |

| Bottom | 275.62 | 280.96 |

This shows that this insulated shipping box design holds the temperature inside the payload area between 2°C to 8°C for the entire time profile of 96 hs. A new analysis can be done for a winter temperature profile simply by uploading a new temperature curve.

Conclusion

The simulation has shown that, with the given 96 hours profile, the temperature profile of an insulated shipping box can be accurately simulated using a conduction approach. This case study illustrated how simulation can be useful for a quick evaluation of the initial design concepts, as well as subsequent design optimization. Predictive modeling can save both time and money on insulated shipping box design and development, and deliver the final product to the market more quickly.

In this case, we investigated making use of FEA to design thermal packaging for cold chain systems—but this is just one example of how designers and engineers can apply simulation tools in the product development process. The SimScale Public Projects Library has a wide selection of templates simulating various applications of FEA and thermal analysis across many industries, including automotive and transportation, manufacturing, and industrial equipment.

Explore it by creating a free Community account.

SimScale’s CEO David Heiny tests the capabilities of the platform to solve a real-life engineering problem. Fill in the form and watch this free webinar to learn more!

References

- World Economic Forum, Global Risks Report 2016, https://www3.weforum.org/docs/GRR/WEF_GRR16.pdf

- World Economic Forum 2013, Outlook on the Logistics and Supply Chain Industry 2013

- Food and Agriculture Organization of the United Nations, Food wastage footprint: Impacts on Natural Resources, https://www.fao.org/docrep/018/i3347e.pdf

- Pharmaceutical Commerce 2015, The Cold Chain Directory 2015: The 2015 Biopharma Cold Chain Landscape, https://pharmaceuticalcommerce.com/lib/sitefiles/pdf/Cold_Chain_Dir_2015.pdf