SimScale has maintained a consistent effort in ongoing upkeep of its platform while continually introducing novel simulation capabilities to enhance user simulations and accelerate innovation. In Q3 2023, SimScale unveiled eagerly awaited enhancements to its product, such as temperature-dependent material properties, humidity source modeling, non-Newtonian fluids, and modal-based harmonics, to name a few. SimScale also released its latest physics, electromagnetics, to complement its multiple physics suite of simulation capabilities, including fluid dynamics, structural analysis, and thermal analysis.

In this product update, let’s dive into the latest pivotal features introduced by SimScale in the third quarter of 2023.

- Temperature-dependent material properties for CHT v2.0 & IBM

- Humidity Sources Modeling

- Visualization/Computation of Local Mean Radiant Temperature (MRT) Without Solar Load

- Parametric Mesh Study on IBM Mesh Fineness

- Multiphase/Subsonic Features

- Rotating Machinery – Blade-to-blade Flow Visualization

- Automated Sweep Meshing for Structural Analyses

- Orthotropic linear mechanical material properties in the cartesian coordinate system

- Modal-Based Harmonics

- Yeoh Hyperelastic Model

- Ogden Hyperelastic Model

- Select Similar Shapes

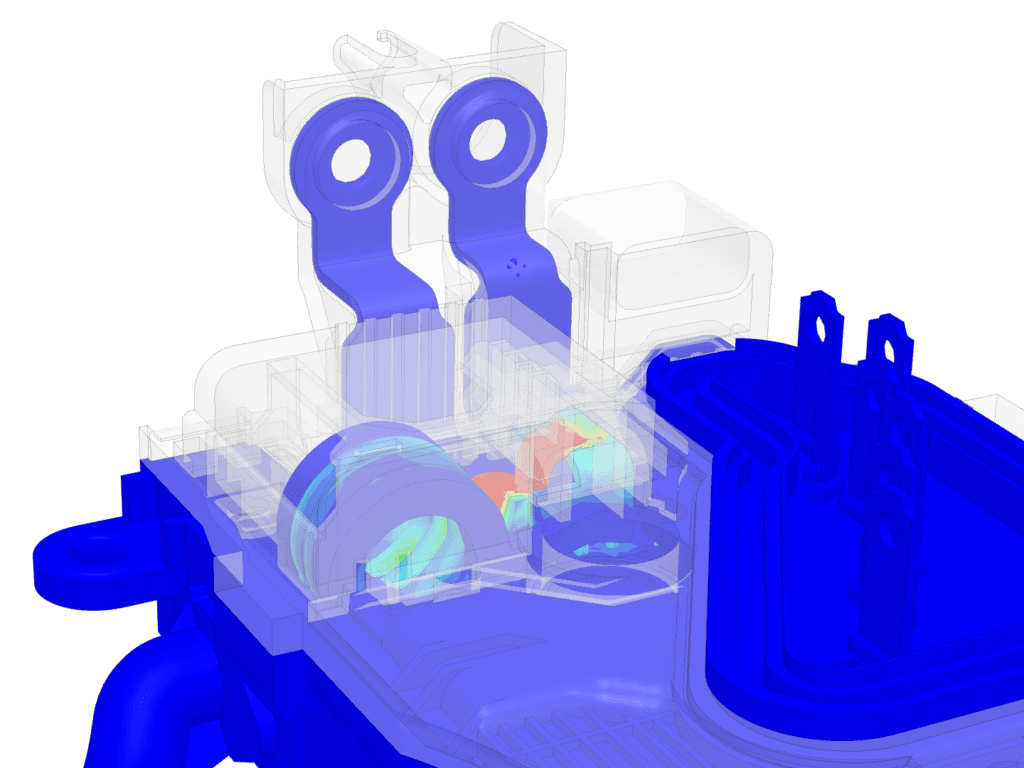

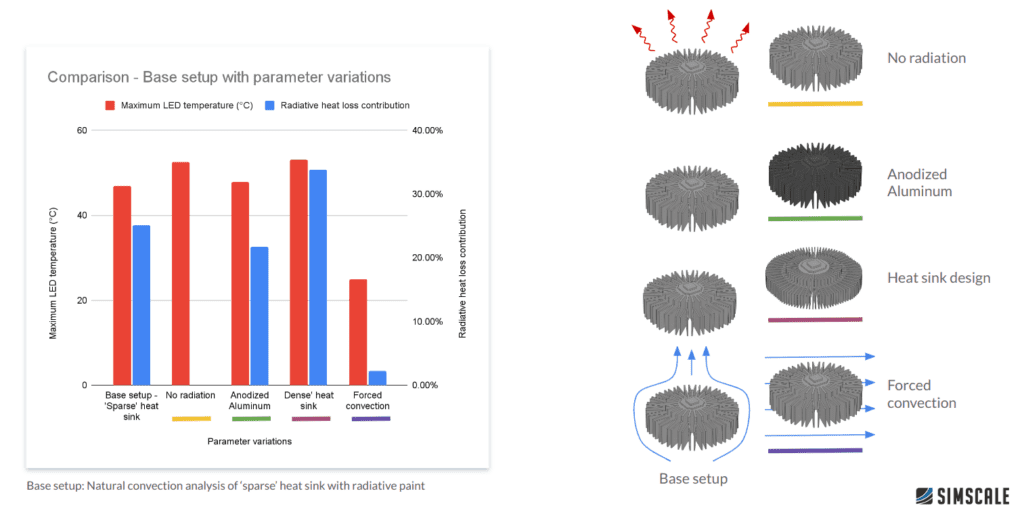

1. Temperature-dependent material properties for CHT v2.0 & IBM

CHTv2/IBM simulations now allow for the definition of more advanced fluid properties through temperature-dependent tables:

- Specific heat

- Dynamic viscosity

- Kinematic viscosity

- Prandtl number

- Density

This means that our users can more accurately model specific material properties.

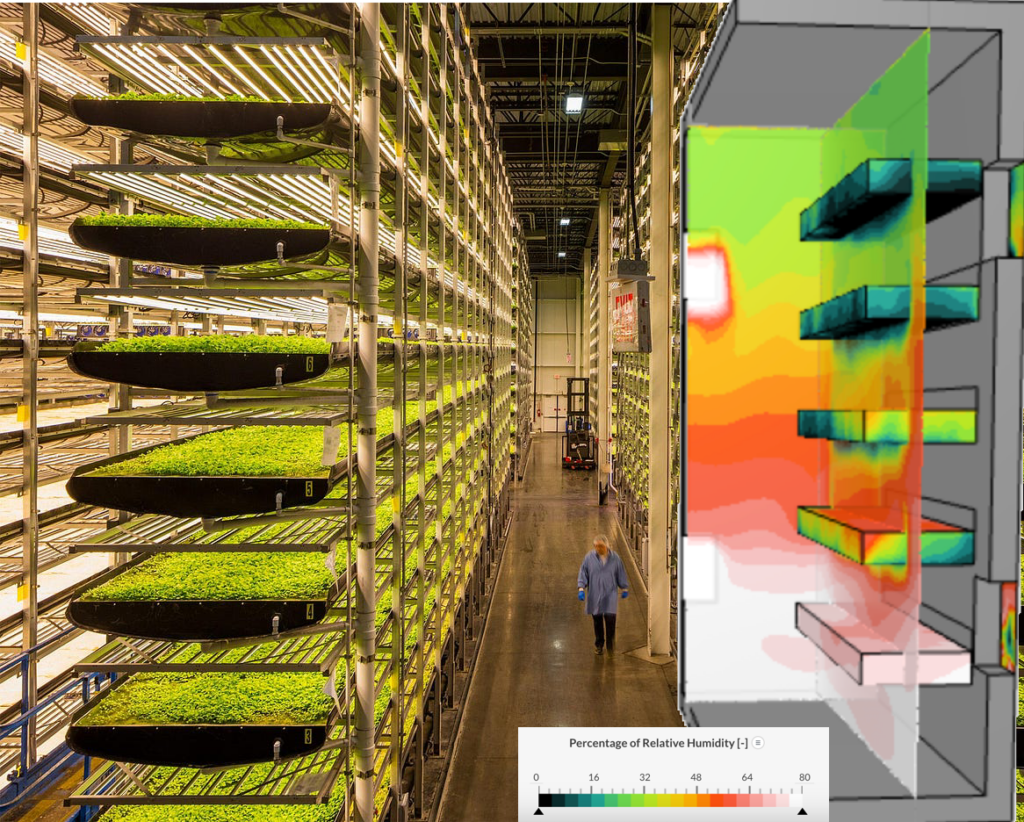

2. Humidity Sources Modeling

3D humidity sources are now available as a new advanced concept for humidity modeling. Attention has been paid to the robustness and stability of simulations in the presence of humidity sources. They can be used to model humidifiers.

The specification of the humidity type for fixed value boundary conditions has been added. The possibility of modeling a humidity source on a wall is also included.

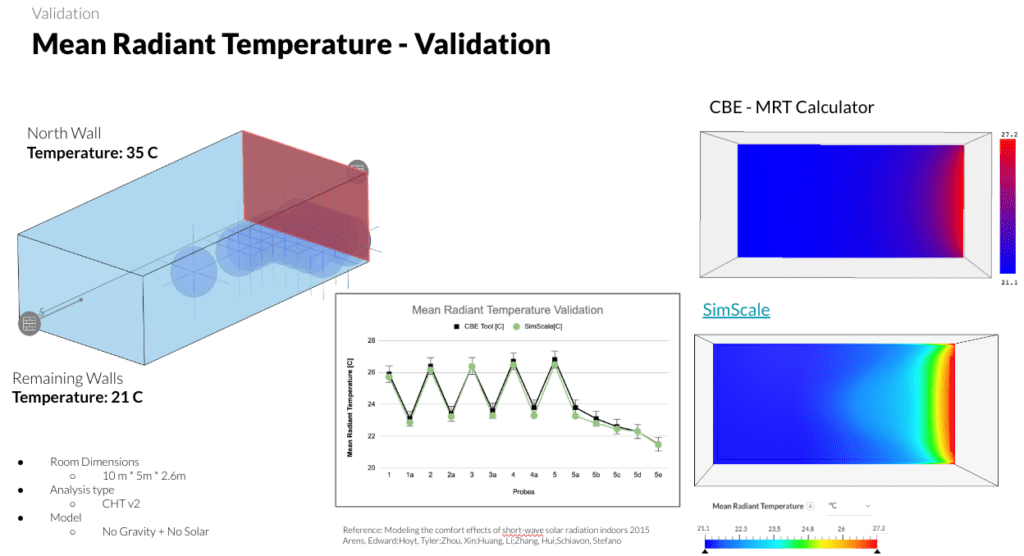

3. Visualization/Computation of Local Mean Radiant Temperature (MRT) Without Solar Load

CHTv2 simulations now allow the calculation of the Mean Radiant Temperature field on fluids. This field indicates the temperature due to radiation heat transfer at a given point and can help quantify the radiant heat exchange between a person and their surroundings.

4. Parametric Mesh Study on IBM Mesh Fineness

The automatic mesh fineness slider in IBM (Immersed Boundary Method) now supports parametric runs, allowing for parallelized mesh independence studies.

5. Multiphase/Subsonic Features

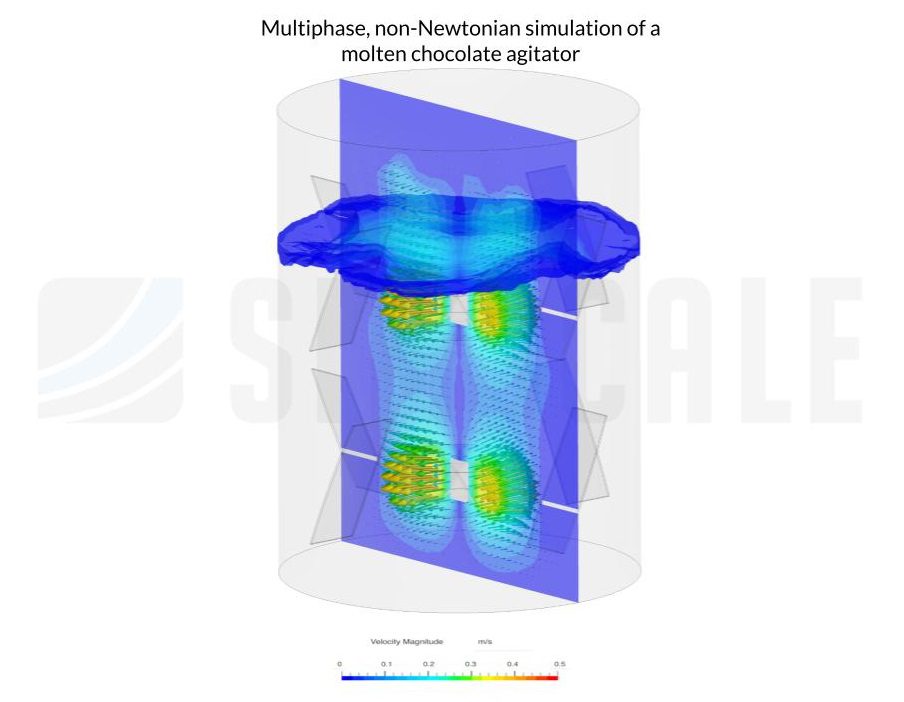

5.1. Non-Newtonian Fluids Available

Our users can now model non-Newtonian fluid behavior in the Subsonic solver using the Herschel-Bulkley model.

This captures the correct physics of highly viscous, non-Newtonian fluids like motor oil and blood, combined with advanced CFD capabilities like multiphase and cavitation.

5.2. Time-Dependent Boundary Conditions

Time-dependent boundary conditions for most variables are available for transient analyses in Subsonic. Users may specify Velocity, Flow rates, Pressure, and Temperature at inlets and some outlets as functions of time in the form of a table input.

5.3. Probe Points as Result Controls

Probe points for Subsonic analyses are now available under the Result Controls. The number of parameters written out will vary depending on the type of simulation chosen.

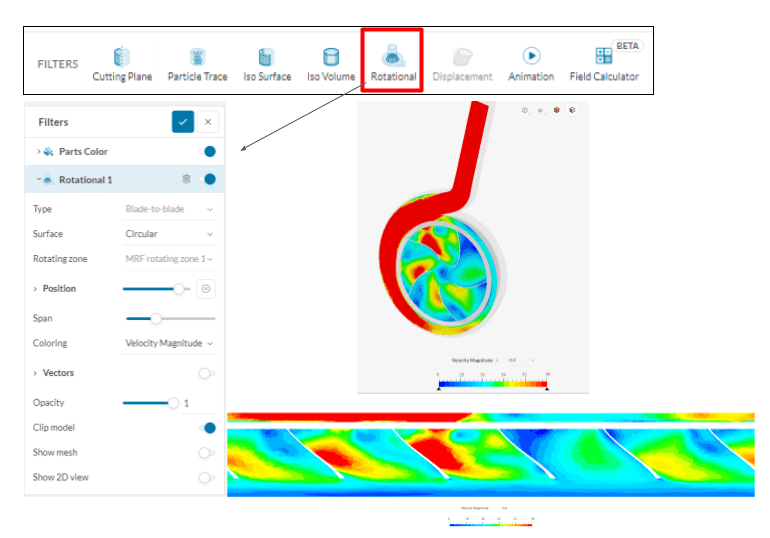

6. Rotating Machinery – Blade-to-blade Flow Visualization

The newly released feature is a post-processing filter called “Rotational” that allows users to analyze flow through a cascade of blades. Mesh, flow vectors, and contours can be visualized on a 2D unwrapped plane of the blades, and the images can be exported.

This feature is currently available for centrifugal-type turbomachines. We will soon be releasing cascade views for axial impellers as well as meridional cut plane visualization.

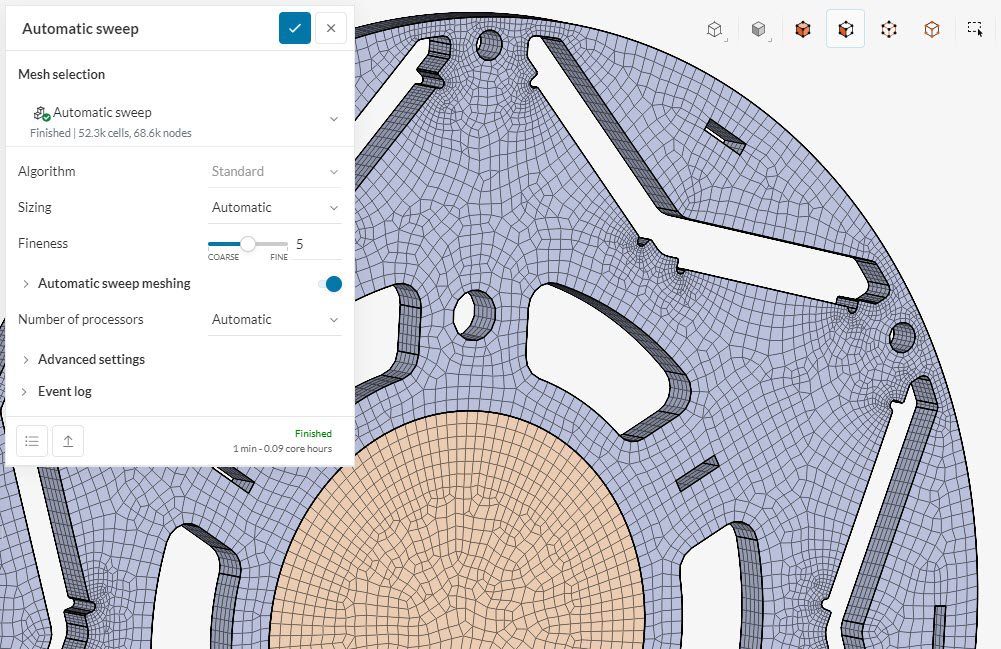

7. Automated Sweep Meshing for Structural Analyses

Enable the toggle to automatically mesh bodies with continuous cross-sections using prismatic elements.

Prismatic elements such as hexahedral and wedge elements outshine standard tetrahedral elements in terms of accuracy and performance. With this feature, users can automatically benefit from swept meshes without the need for manual refinement.

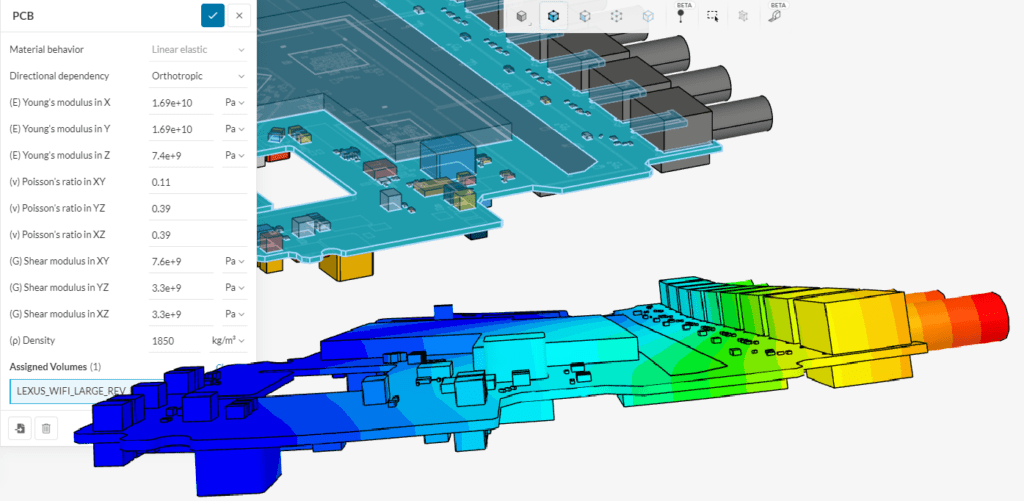

8. Orthotropic linear mechanical material properties in the cartesian coordinate system

Our users now have the ability to create solid materials with orthotropic linear elastic behavior in which Young’s modulus, Shear modulus, and Poisson’s ratio are defined independently for the three mutually perpendicular cartesian directions. This allows for simple modeling of PCBs and composite structures in which material orthotropy can significantly influence peak stresses and deformations.

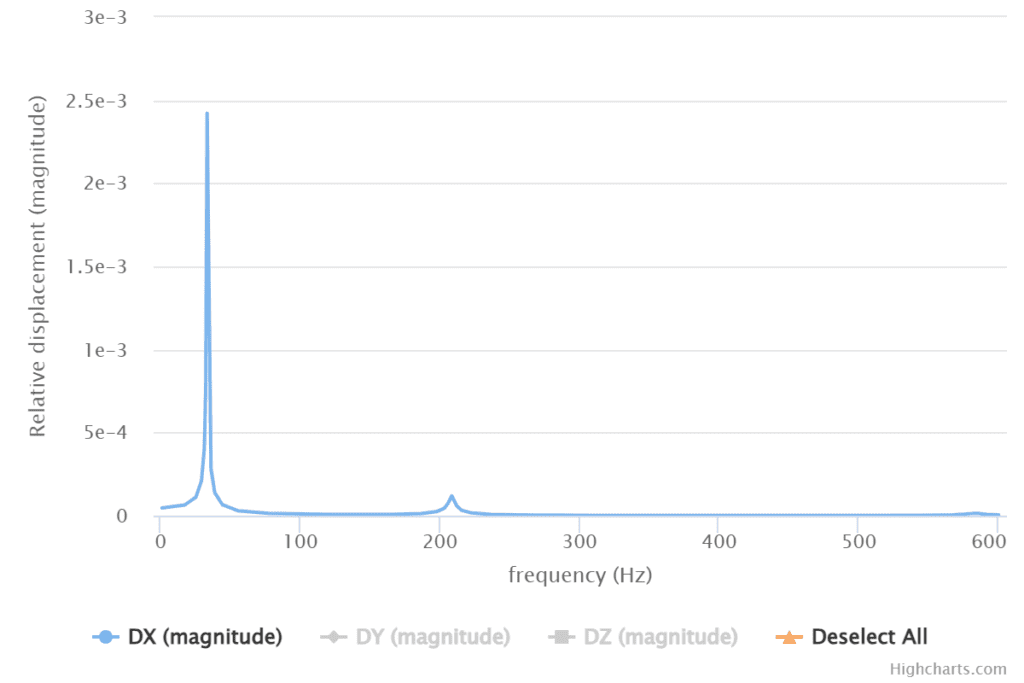

9. Modal-Based Harmonics

Supercharge your vibration analysis with Modal-based Harmonic analysis. This feature allows for efficient computation of many excitation frequencies, even for large mesh sizes! The new analysis method combines frequency and harmonic analysis into a single analysis, streamlining workflows and enabling users to automatically capture resonant behavior.

9.1. Automatically Capture Resonant Response in Modal-based Harmonic Analysis

Frequency responses of vibrating systems can now be resolved at high resolution using two new automation options for setting excitation frequencies in Modal-based Harmonic analysis:

- Cluster around modes: Harmonic loads are applied at frequencies clustered around eigenfrequencies.

- Cover spectrum: Harmonic loads are applied at frequencies clustered around and in between eigenfrequencies to fully capture the entire spectrum.

These options provide a super simple and automated process for capturing resonant behavior, accurately allowing users to confidently check peak values such as maximum deflection, acceleration, and stress.

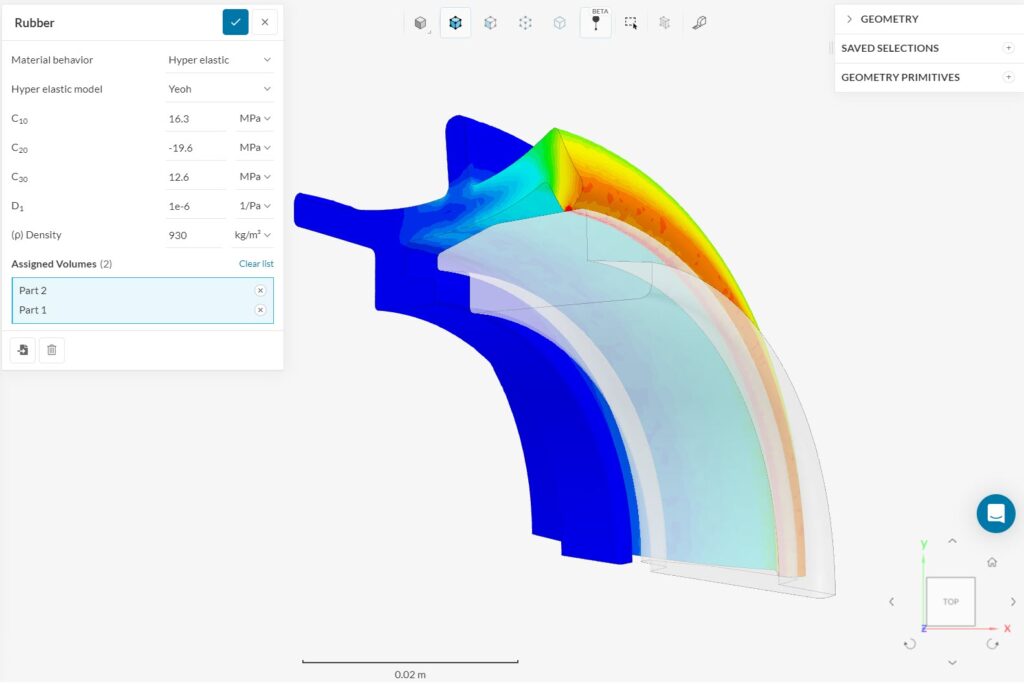

10. Yeoh Hyperelastic Model

A powerful and user-friendly Hyperelastic model, Yeoh has great stability and requires only uniaxial experimental data for adequate fitting. This versatile model can capture up to 700% strains in elastomers.

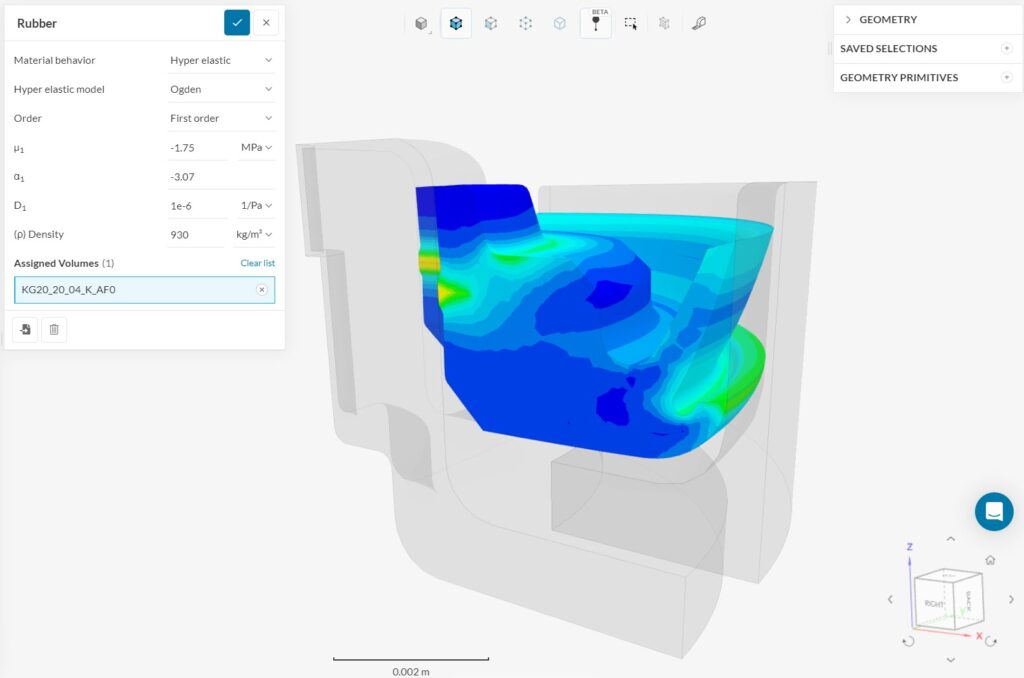

11. Ogden Hyperelastic Model

This sophisticated hyperelastic model enables accurate modeling of rubbers and biological material at very high strains.

Here’s what you should know about it:

- Accuracy: The Ogden model boasts accuracy, outshining other hyperelastic models in predicting material deformation.

- Complexity: We’ve added options for model complexity – 1st, 2nd, or 3rd order. Allowing some flexibility when fitting the model to stress-strain relations with various levels of complexity.

- Data fitting: To get the best results, you’ll need extensive experimental data, covering all three deformation modes (Uniaxial, Pure shear, Biaxial).

12. Select Similar Shapes

Our users can now Expand face selection by “Tangent faces”, “Same area” or “Same filet radius”. You will find this in the ‘right-click’ menu.

Note: The selection of similar bodies and selection of similar edges will be added at a later date.

Take These New Features for a Spin Yourself

All of these new features are now live and in production on SimScale. They are really just one browser window away from you!

If you wish to try out these new features for yourself and don’t already have a SimScale account, then you can easily sign up here for a trial. Please stay tuned for our next quarterly product update webinar and blog.