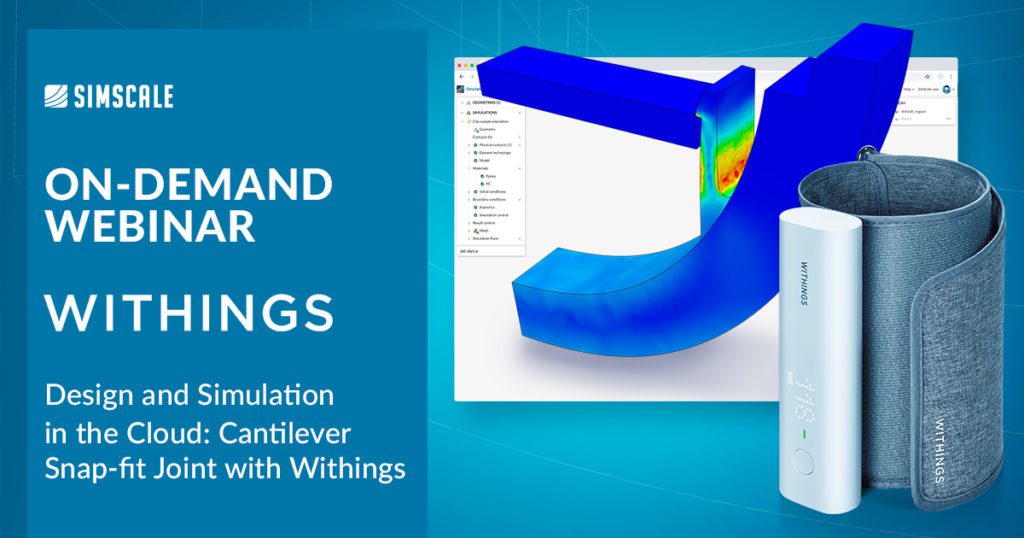

Withings® is a French medical device company that designs and manufactures clinically validated smart health devices and associated apps. An example of Withings’ product is the BPM Connect® – a compact blood pressure measuring device for home use.

To assemble, the BPM Connect uses snap-fit joints just like many compact devices from the medical and electronic industry. Snap-fit joints are a commonly used design for connecting plastic parts. They are a good replacement for fasteners such as screws or rivets, as they weigh less and are easier to assemble. Moreover, they are easy to deploy as they can be directly assembled after injection molding without any post-processing. However, designing the right snap-fit joint can be very difficult and expensive. Validating the correct function of snap-fit joints can be prototype-intensive. Additionally, mock-ups don’t represent the actual assembly well because they have different material properties due to the different manufacturing processes (CNC-modeling vs injection molding).

Enter SimScale! Simulation can help reduce the number of prototypes leading to shorter design rounds. Using SimScale, an engineer can calculate insertion/extraction forces and can visualize section stresses to recognize problematic zones inside the snap-fit material. This is important to allow a design-for-assembly approach.

In this article, we demonstrate the structural analysis of the snap-fit joint shown in the image below, which is similar to the ones used in the BPM connect. We will discuss how a company like Withings is able to reduce their design-to-prototype cycles from weeks to days by leveraging the power of the cloud for simulation.

Case Study: Structural Analysis of a Snap-Fit Joint

This case study deals with a static structural setup. However, it is also a nonlinear analysis due to the large deflection of the beam and the nature of the physical contact between the catch and the mating part. The insertion and extraction of the snap-fit are imposed by defining the displacement or movement of the plastic casing in dependence of time. The goal of this design study is to visualize and calculate the maximum stresses, deformations, and mating forces for different tolerances of the same design. We will be considering three different cases:

- A nominal case

- Minimum tolerance values and the smallest gap between catch and mating part

- Maximum tolerance values and the largest gap between catch and mating part

Simulation set-up

The first step is to import the CAD geometry either by uploading a file (drag & drop) or by importing directly from your preferred CAD tool. SimScale supports the import of most common CAD file formats, and also provides CAD Associativity for OnShape, Solidworks, and Fusion 360 meaning that you can switch CAD geometry and the simulation assignments of loads and boundary conditions and materials are automatically applied to the new geometry. This is useful in this project as we do not need to redo any assignments when changing between the tolerance cases. Simscale also allows for the setup of templates that can be used by engineers with less experience in simulation.

The next steps in the simulation setup are defining the physical contact between the catch and the mating part, setting the materials, and defining the boundary conditions. The beam is defined to move into the mating part and out of it again.

Snap-Fit Tolerance Study

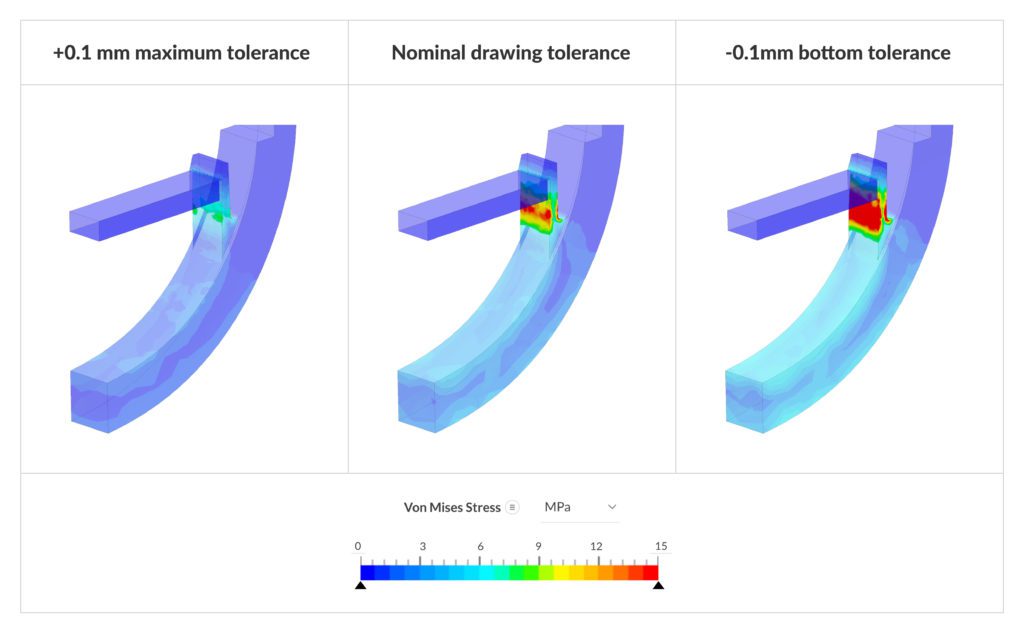

The image above juxtaposes stresses in the three different tolerance cases. These three simulations ran in parallel to each other. In SimScale a new virtual machine is started in the cloud with every simulation run. This means that if one simulation takes one hour, ten simulations will also take one hour. This parallelization allows for iterative simulations in early-stage design.

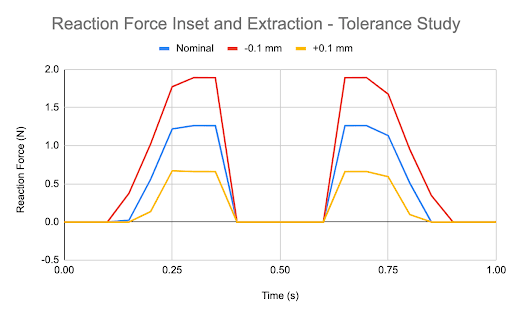

We can clearly see how on the right the stresses are highest due to the fact that the gap between both parts is small. In the next plot, we can see the required forces to insert and extract the snap-fit. As expected, the tolerance with the smallest gap requires a significantly higher force than the other two cases. An engineer can judge if the mating force, in this case, is too high for ergonomic assembly and disassembly of the snap-fit. Conversely, in the case with the largest gap, the extraction force might be too small such that there is a risk that the snap-fit can loosen or break apart. SimScale provides a powerful tool to assess these design concerns.

Benefits of Nonlinear Simulation

This case study shows how nonlinear static analysis in early-stage design allows engineers to optimize the design for an efficient assembly and also for correct functionality. With SimScale, Withings is able to validate the correct function of snap-fit joints, like those used in their at-home and wearable medical devices. The accessibility of cloud-native engineering simulation enables designers and engineering teams to leverage parallel computation capabilities and achieve faster design cycles and more robust design insights.

To learn even more about this nonlinear mechanical optimization study, watch our on-demand webinar with Withings. Simulation experts from Withings and SimScale showcase how to accelerate the design-to-prototype cycle of medical devices: