Rimac Automobili was founded in 2009 from a vision to create high-performance cars for the electric era. Today, they are a 1100-people strong technology powerhouse focused on designing, engineering, and producing electric hypercars and high-performance EV components for the global automotive industry. Their engineering team creates core EV systems in-house, from power-dense drivetrain systems to a highly advanced autonomous-driving and unique user experience enabled through our infotainment technologies.

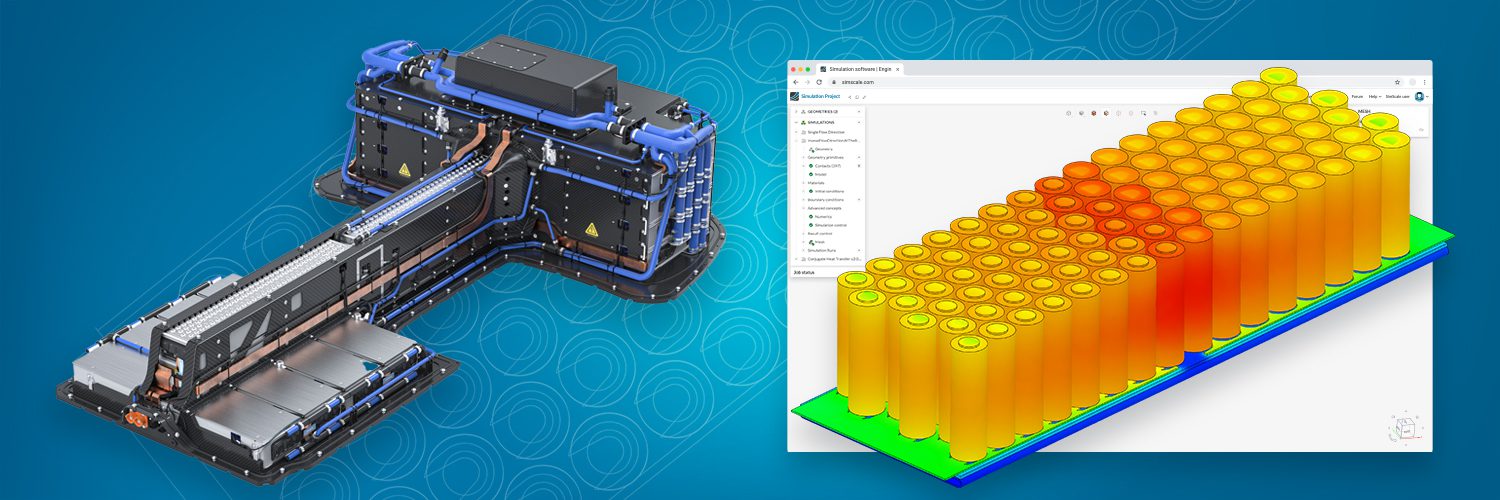

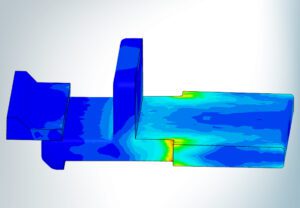

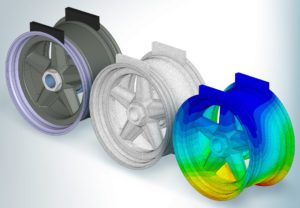

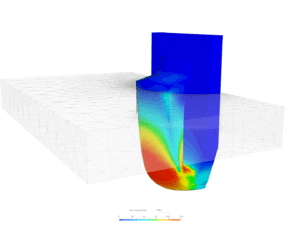

Thermal management is one of the greatest challenges in electric vehicle production. Rimac Automobili’s range of partly sunken, liquid- or air-cooled thermal management solutions ensures all the cells in their battery packs remain within optimal temperature ranges. This ensures the batteries meet required performance without sacrificing lifespan. In order for Rimac to stay at the top of their field, it is crucial for them to simulate a wide range of battery operating conditions, cooling concepts, and different environmental conditions for different projects. Not only is it time-intensive to manually set simulations for every different condition but the limitations of traditional CAE systems mean it can take days, sometimes months, to get results dramatically impacting the time-to-market transition for the next generation of hypercars. For Rimac Automobili, the adoption of digital prototyping means exploration of the full design space with the desired accuracy and a reduction in the trial-and-error that comes with physical prototyping, whether that includes thermal, structural, or fluid flow simulations. This case study explores a thermal simulation of a liquid-cooled battery pack using SimScale’s CHT (Conjugate Heat Transfer) module.

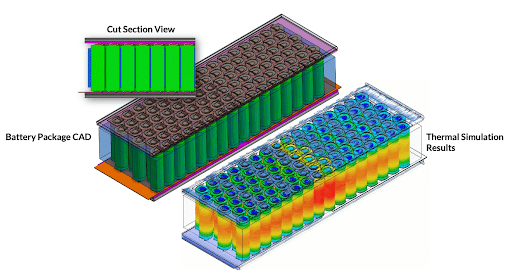

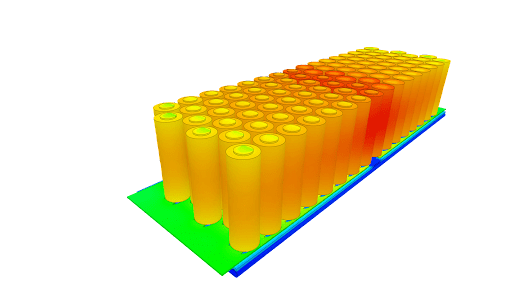

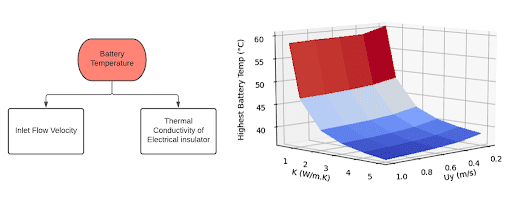

Rimac’s Battery System engineer Antonio must evaluate various parameters but is primarily concerned with the maximum temperature that can occur in the battery cells. As overheating affects passenger safety, staying within the temperature limits set for the battery cells is critical.

The second key parameter examined is the thermal gradient across the battery module. With a high thermal gradient, battery cells will behave differently as their performance depends heavily on temperature. Non-uniformity throughout the battery module reduces battery life and negatively impacts other relevant performance issues.

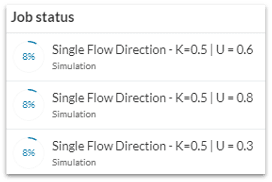

In this case study, Rimac used the conjugate heat transfer (CHT) analysis type to include all mechanisms of heat transfers, primarily conduction and convection, that play a role in investigating the parameters previously mentioned. The case was simulated using a steady-state approach and laminar flow, resulting in a total run time of 13 hours for 30 simulations. That would have represented around 300 hours if done in a serial fashion. In other words, 96% time-saving.

When performing physical testing, the limitation of the real geometry drastically limits the observable design space. Parameters such as the flow velocity or the inlet temperature can be influenced. However, it is rather difficult to vary parameters such as the thermal conductivity of materials or the thickness of various installation layers, which are easy to adapt in a simulation setup.

The initial parameters of interest for such studies usually are the temperature of the battery coolant and flow rate. For this study, Rimac limited the design space to the inlet flow velocity of the coolant and the thermal conductivity of the electrical insulator.

The parameter space can easily be increased as Antonio has shared that there are “many different key factors that you can account for, and you can obviously plot this in any way you’re really interested in.” Essential to this study is that the highest battery temperature can be ascertained based on the key parameters selected. It is possible to go for any number of parameters as long as it is economically feasible and, with SimScale these economic barriers are removed as it is possible to run hundreds of design iterations in parallel.

Using SimScale in the early R&D stages of the product, we were able to fully leverage simulation capabilities into our product design process. This allowed us to quickly set up different cooling scenarios for our battery cells using SimScale's CHT module to efficiently analyze the impact of design changes on battery module performance.

Antonio Radenić

Battery System Engineer at Rimac Automobili

Rimac incorporates SimScale as much as they can into their R&D cycle, especially for thermal management of their battery packs. Cloud-native simulation allows their designers and engineers to investigate the impact of various geometry changes of cooling plates and pipes, and also to determine what pressure drop values they can expect on different CAD geometries.

Keeping multiphysics simulation accessible and organized in a single SaaS platform rids Rimac of IT complexity while offering various analysis types to explore and expand the design space of their products. Their designers are empowered with a more robust understanding of the physical behavior of their products. And, with simulation templates and live customer support, they continue to build upon their simulation expertise.

Most importantly, Antonio shares that cloud-native simulation enables Rimac to accelerate and enhance their design and development process. Rapid prototyping and the flexibility to adapt designs to always include the latest EV technology are essential in their industry and critical to Rimac’s competitive edge.

Watch the related on-demand webinar with Rimac to see how they achieve faster product development for EVs with cloud-native engineering simulation.

Sign up for SimScale

and start simulating now