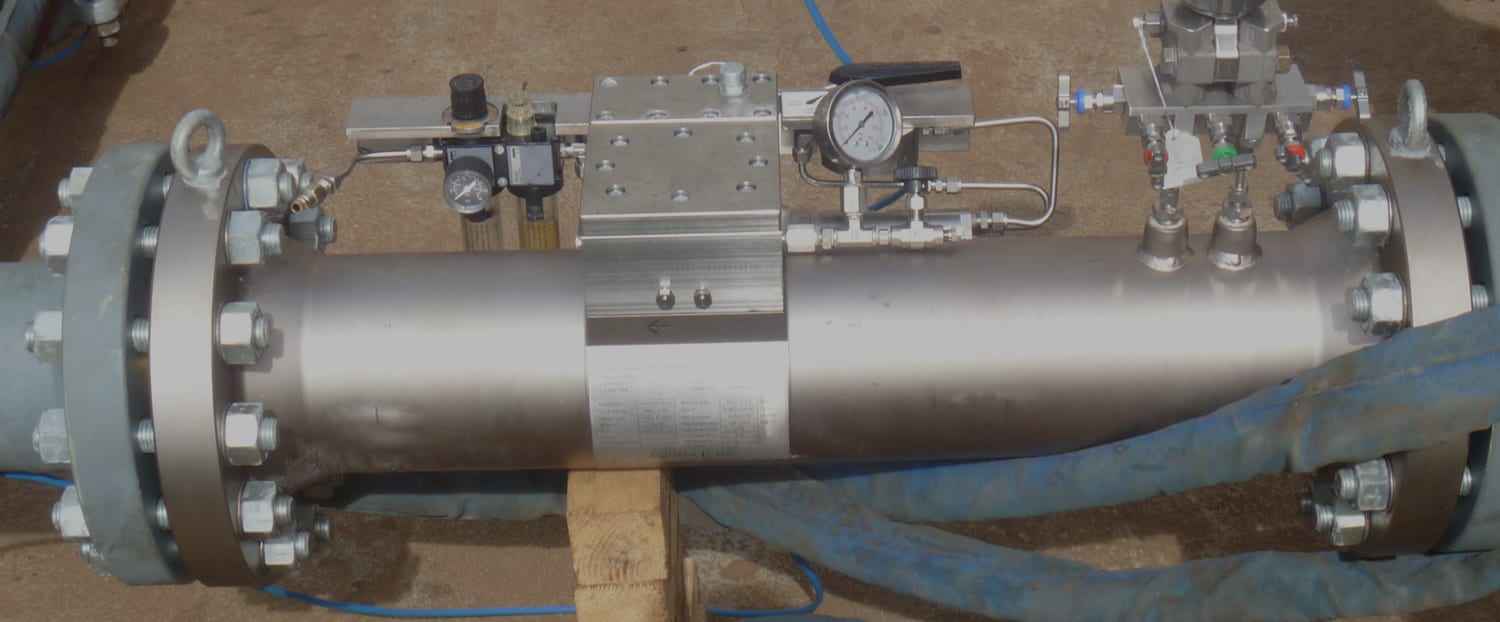

Within the oil and gas sector, there are many challenges to overcome before products are deemed safe for sale. For instance, flow measurement devices must be designed to withstand the pressures and flows generated by the production and extraction of hydrocarbons without failing.

At the same time, these devices must give optimal measurements that are reliable for production and control purposes. Simulation is then crucial to evaluate the performance of these devices.

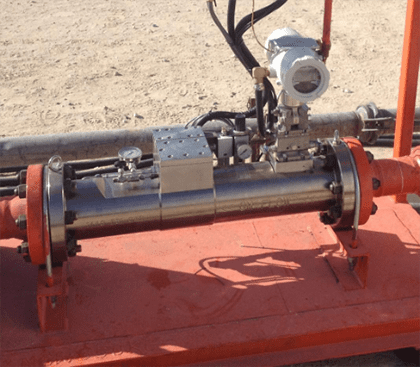

Being a small company, prototyping costs are important to GM Flow and can impact directly their results and growth. With this in mind, GM Flow’s team chose to use CFD simulation in the early phase of product development in order to reduce the number of devices to prototype and physically test.

SimScale support helped us understand and make the best and most efficient use of the simulation platform. It’s been a very good experience!

Gavin Munro

Managing Director at GM Flow Measurement Services Ltd

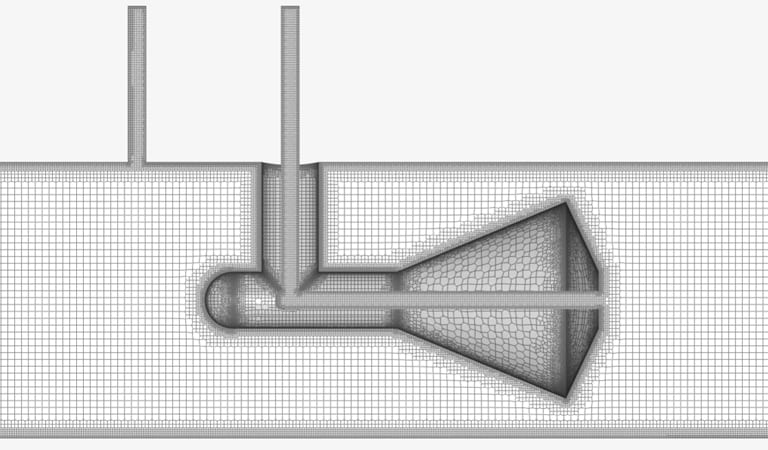

GM Flow wanted to assess the performance of three different design approaches for a new size of flow measurement device prior to physical validations. The geometries were then uploaded into SimScale for meshing. With the new end-to-end workflow environment, the GM Flow engineers could mesh, simulate, and post-process the results in one single place.

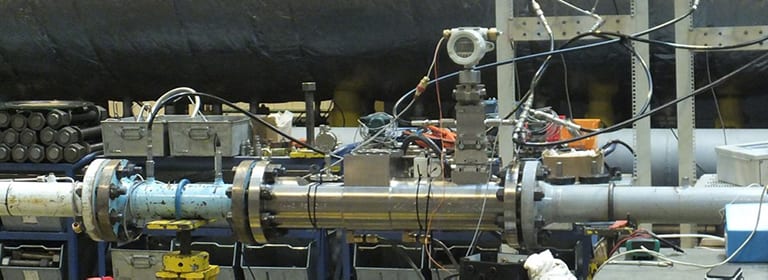

For meshing, the hex-dominant automatic mode was used to generate a 2-million cell mesh. The automatic mesher added refinements such as boundary layers, region, and feature refinements. The mesh operation took for each geometry around 15 minutes to complete using 32 cores.

As SimScale runs on the cloud, Gavin Munro and his team created all three meshes in parallel which then helped him to be able to start the three different simulations almost at the same time.

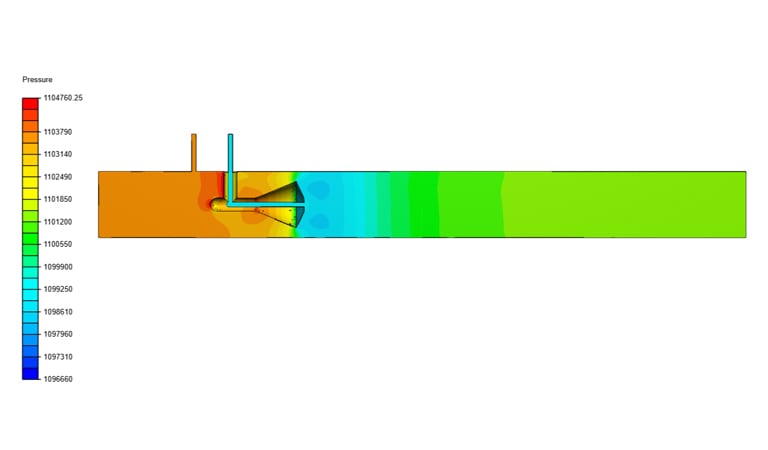

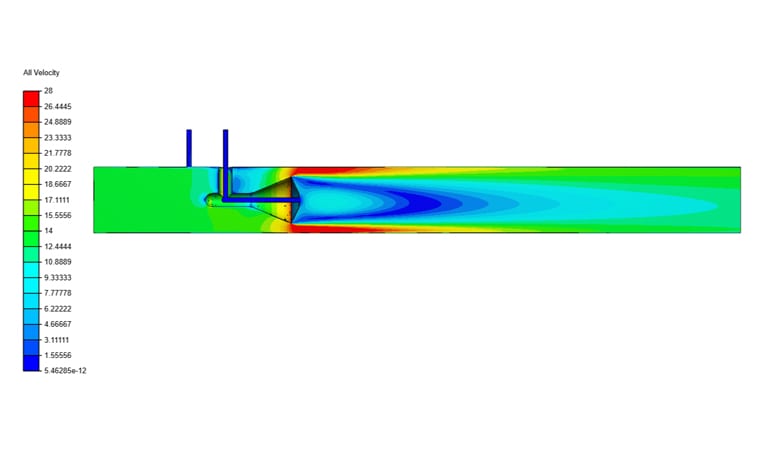

Compressible fluid flow simulations were then performed using 96 cores to run. A customer boundary condition was used for the inlet to control the mass flow as a function of the turbulent kinetic energy and specific dissipation rate. Other boundary conditions used were pressure outlet, symmetry and no-slip walls. These simulations took around 50 minutes each to finish.

The main goal of the compressible simulations was to calculate something called the “discharge coefficient”. This is a function of two specific surfaces within the device, calculated based on the values obtained from SimScale. When compared to the physical measurements, it matched the value by 95%.

This gave even more confidence to GM Flow to continue to use SimScale for CFD during the design phase.

Not only was the discharge coefficient measured, but also the velocity behaviour of the fluid. This would need to be within a specific range of velocities to guarantee safety, and to avoid vibrations on the line which could damage the device.

“We have never used computer-aided engineering (CAE), and SimScale made it simple to start with. The support team was fundamental to bring us up to speed. The fact that it is cloud-based is a great aspect of SimScale; as it made it possible for us do some small changes on the CAD and simulate all proposals in parallel to see what was changing.”

GM Flow continues to use SimScale to run CFD simulations in the cloud.

Sign up for SimScale

and start simulating now