Using the SimScale platform, Optimized Safety Solutions (OSS) expected to obtain high quality, professional images and animations which could then be used to present and discuss results with safety professionals—many of them not familiar with CFD.

This project aimed to visualize the concentration and flow pattern of diesel exhaust fumes entering a warehouse from the outside environment. With a desire to present the results at the National Safety Conference, OSS had a tight deadline that it had to adhere to.

Already familiar with basic CFD simulations, OSS decided to jump into CAE software and incorporate it into the workflow to obtain improved visualization of results for air ventilation systems related to health concerns. OSS came to SimScale looking to visualize air and fume distribution and concentration in order to understand the flow behavior. This would allow the OSS team to test different ventilation designs based on varying factors such as combining different flux sources or changing fan speed.

Starting from the CAD model of the warehouse, OSS then needed to generate the inner fluid volume in the platform. This would allow them to simulate how the flume entered and was dispersed all over the room.

This case involved one steady simulation that took just 37 minutes to run, using 20 core hours. The analysis type chosen was a steady-state incompressible CFD simulation with a k-omega SST turbulence model and a passive scalar to model fume diffusion. The warehouse was modelled with a 10 m/s fume inlet condition and took into account natural ventilation from open windows. A hex-dominant mesh with automatic coarse fineness was used for this simulation. This included 1.7M cells, meshed in 17 min and 9.6 core hours.

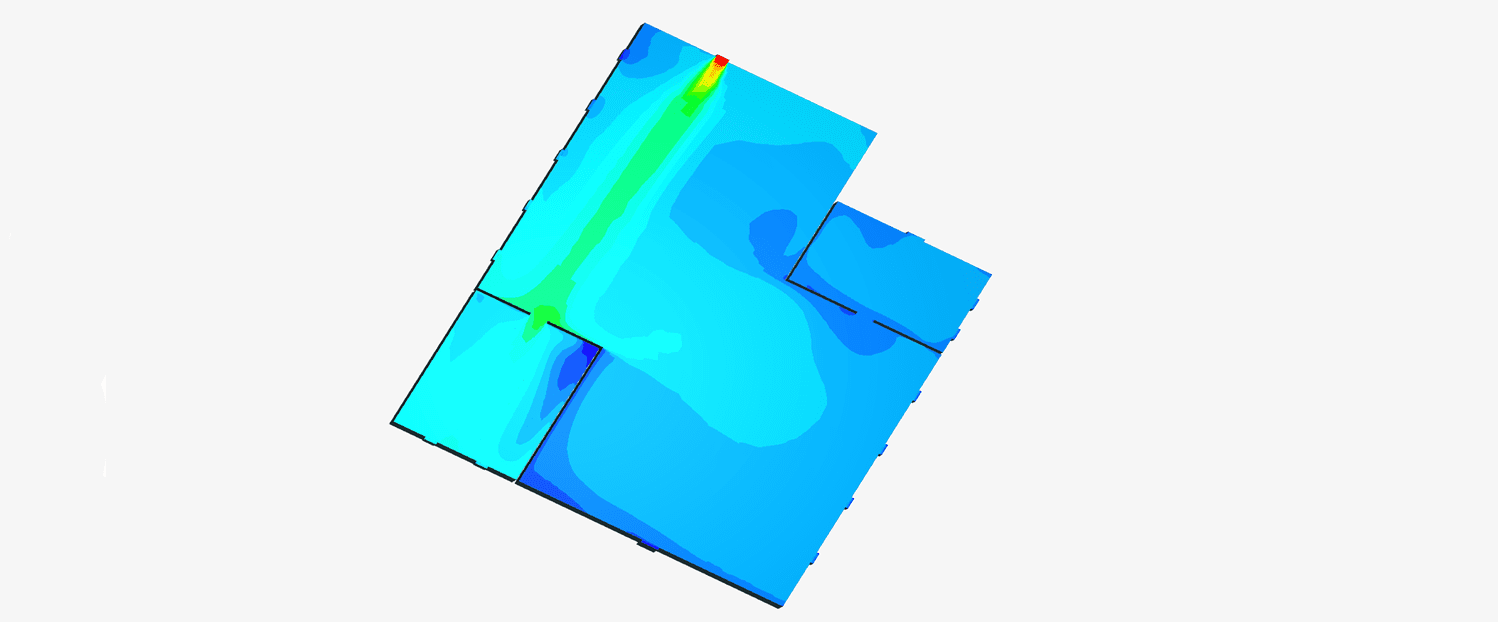

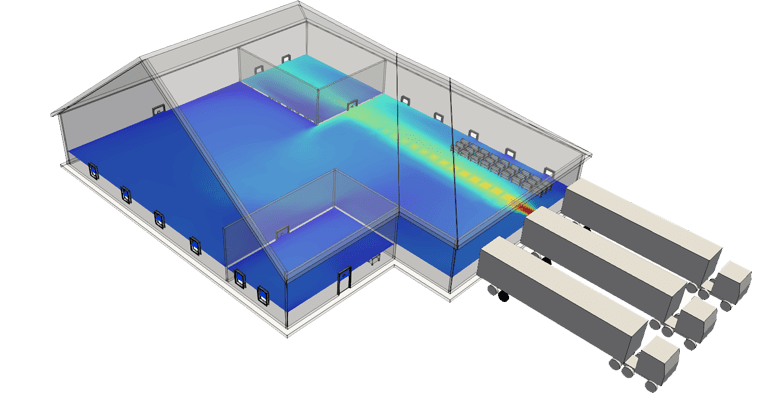

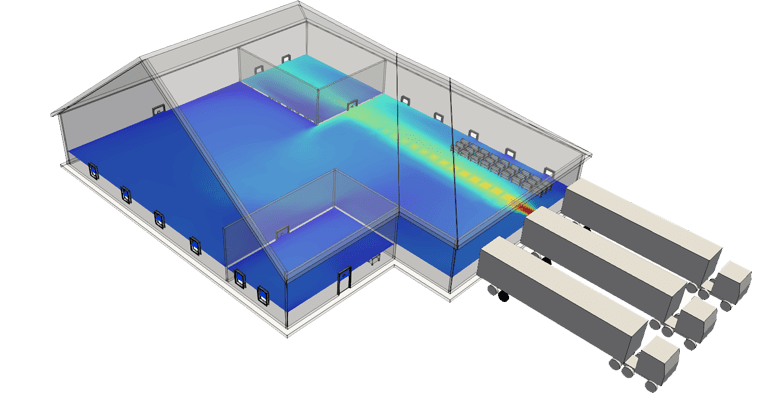

The results of the simulation showed the flow velocity at different sections and the contaminant spread through the warehouse. Using these, an animation was created, demonstrating the increasing contaminant concentration inside the warehouse with an isovolume.

“Thanks to the support of SimScale application engineers, steady results were obtained fast so more time could be spent on post-processing to make the most out of the simulation.”

Having simulated smoke distribution in the room with SimScale, OSS could then generate marketing-oriented post-processing images and animations. In this way, geometries that were not needed for the simulation (such as the trucks bringing smoke into the warehouse) could simply be added later and professional rendering could be performed.

Using SimScale allowed for simulations created with optimized speed and minimized cost outlay. As a result, multiple simulations with different inlet conditions or ventilation systems could be tested in parallel.

Thanks to the support of SimScale application engineers, steady results were obtained quickly which allowed for more time to be spent on post-processing to ensure the simulation could be used to its best advantage.

Sign up for SimScale

and start simulating now