Bühler is driven by its purpose of creating innovations for a better world, balancing the needs of economy, humanity, and nature. As a relevant solution partner for the food and mobility industries, Bühler has developed a pathway to achieve a 60% reduction of greenhouse gas emissions in its operations by 2030, meaning Greenhouse Gas Protocol Scopes 1 & 2, against a 2019 baseline. It has committed to having solutions ready to multiply by 2025 that reduce energy, waste, and water by 50% in the value chains of its customers. Billions of people come into contact with Bühler technologies as they cover their basic needs for food and mobility every day. Two billion people each day enjoy foods produced on Bühler equipment, and one billion people travel in vehicles manufactured using parts produced with Bühler technology. Countless people wear eyeglasses, use smartphones, and read newspapers and magazines – all of which depend on Bühler process technologies and solutions. Having this global relevance, Bühler is in a unique position to turn today’s global challenges into sustainable business. Bühler contributes to safely feeding the world and is doing its part to protect the climate, producing solutions that make cars, buildings, and machinery more energy efficient.

Bühler spends up to 5% of turnover on research and development annually. In 2022, some 12,700 employees generated a turnover of CHF 3.0 billion. As a Swiss family-owned company, Bühler is active in 140 countries around the world and operates a global network of 105 service stations, 30 manufacturing sites, and Application & Training Centers in 23 countries.

Engineering teams need to leverage cloud-native CAE (Computer Aided Engineering) tools to obtain faster insights into their product development to rapidly develop competitive products. Designers are demanding access to robust end-to-end design, simulation, and optimization tools in a web browser, leading to the advent of the all-cloud engineering software stack. This makes it easy to provide global teams with access to simulation tools early in the product life cycle and disrupts traditional R&D workflows.

Bühler showed how a large group of engineers distributed globally adopted and deployed simulation tools to collaborate on research and development. Their engineering teams have benefitted from access to simulation via a simple login, with moderated simulation management provided by enterprise-level administration, and collaboration features. These are critical to unlocking deployment at scale by aligning with organizational information and systems policies and also serve to moderate computational resources and cost. All users can access the types of engineering simulations they need, including computational fluid dynamics (CFD) and finite element analysis (FEA).

What Did Bühler Want to Achieve and Why?

Richard Vonlanthen, Simulation Team Manager in Corporate Technology at Bühler, has been pivotal in defining the SimScale rollout at Bühler. The desired impact and preferred outcome defined by Richard and his team was to enable more engineers to simulate earlier and make informed design decisions, whilst controlling overheads and managing quality. This was in the context of:

Simulation with SimScale has helped us to improve the conversations with potential customers, highlighting our innovation capacities, increasing speed of response and savings. In general, we can say that by using simulation during the design process, we can speed up mechanical and process development by weeks or months, reducing the number of necessary physical trials. Moreover, we can avoid expensive warranty cases, depending on the size of the facility or the number of machines at risk. For us, simulation is very much about ‘getting it right the first time’. The deployment was made very easy for us, due to three key factors: (i) no local installation or hardware required, (ii) easy and secure access with single-sign-on, and (iii) fist-class support of the Customer Success and the Support team at SimScale. They proactively engage in onboarding new users, and help promoting SimScale internally.

Richard Vonlanthen

Simulation Team Manager in Corporate Technology at Bühler

Bühler chose cloud-native simulation to offer global access to all engineers while staying in central control of usage and quality. The initial roll-out was to 80+ engineers, growing to 15% of all mechanical and process engineers to have adopted cloud-native simulation. The roll-out is supported by internal experts who provide guidance, support, and simulation templates, and the target is to scale up usage to more than 25% of mechanical and process engineers globally.

Previously, access to simulation software and hardware was restricted to a few specific locations and simulation analysts only. By opting for a cloud-native tool accessible on a web browser from anywhere at any time, Bühler had the opportunity to rapidly increase the number of engineers with access to advanced simulation technology. When COVID-19 hit and office capacities were limited, the browser-based solution provided the additional benefit of leveraging home and hybrid working. Bühler has some of the most competent engineers in its global offices in Brazil, India, Africa, and China. With a cloud-native tool, they could give access to advanced simulation capabilities in a fairer and merit-driven manner that was cost-effective on a per-seat basis.

Engineers using simulation are developing products with the added benefit of advanced simulation to quantify, visualize, and optimize design performance. Using a unique pricing model, Bühler engineers can use simulation when needed on a daily, weekly, or monthly basis without any capacity limitations of scaling usage when needed. At present, 15% of all mechanical and process engineers are using the cloud simulation platform spread across 25 departments in 10 business units on four continents. Engineers have access to all analysis types with the most commonly used being CFD and structural FEA. The roll-out strategy envisages further increasing the user base significantly, to a 10x scale-up compared to the traditional fixed license simulation software Bühler was using. Many teams will have their own preferred CAD packages, meaning that a wide range of geometry formats need accepting and meshing with automation tools facilitating many tedious aspects of simulation setup. An enterprise dashboard is used to track and manage usage globally which allows power users (admins) to offer simulation templates for common analysis types and projects and limit computational cost and deploy training modules.

A fully cloud-native approach to simulation is taking shape at Bühler. Managers are realizing they can now deploy analysis tools company-wide to stay at the forefront of research and development. Cloud-native simulation addresses all the issues discussed above for the first time all at once. Instead of simply providing a physics/simulation tool, it integrates all the above aspects required to make company-wide deployment possible by offering a vertically integrated single tool for:

Simulation experts at Bühler work within an expert team of highly skilled engineers that offer support and guidance to engineering colleagues globally. This core team has been instrumental in deploying simulation using a carefully crafted roll-out strategy that includes software trials, customized training workshops, and accelerated technical support. Their role includes onboarding engineers from diverse teams such as R&D to anyone working in product development from any department of Bühler, often engineers with limited simulation experience. Additionally, the core team provides advanced analysis capabilities as power users of simulation for more challenging analysis projects.

Across the organization, SimScale is deployed on a diverse problem set, from evaluating the structural integrity of large-scale farming equipment to making food processing machinery more energy efficient. Clément Zémerli, a Senior Simulation Engineer in Corporate Technology, works within a highly specialized team of simulation engineers offering advice to other teams and has been involved in the following projects that demonstrate quick wins from deploying SimScale.

Integrating simulation early in the product development process allows to better understand the physics and gain confidence in design choices. With SimScale every design engineer has access to simulation.

Clément Zémerli

Senior Simulation Engineer in Corporate Technology at Bühler

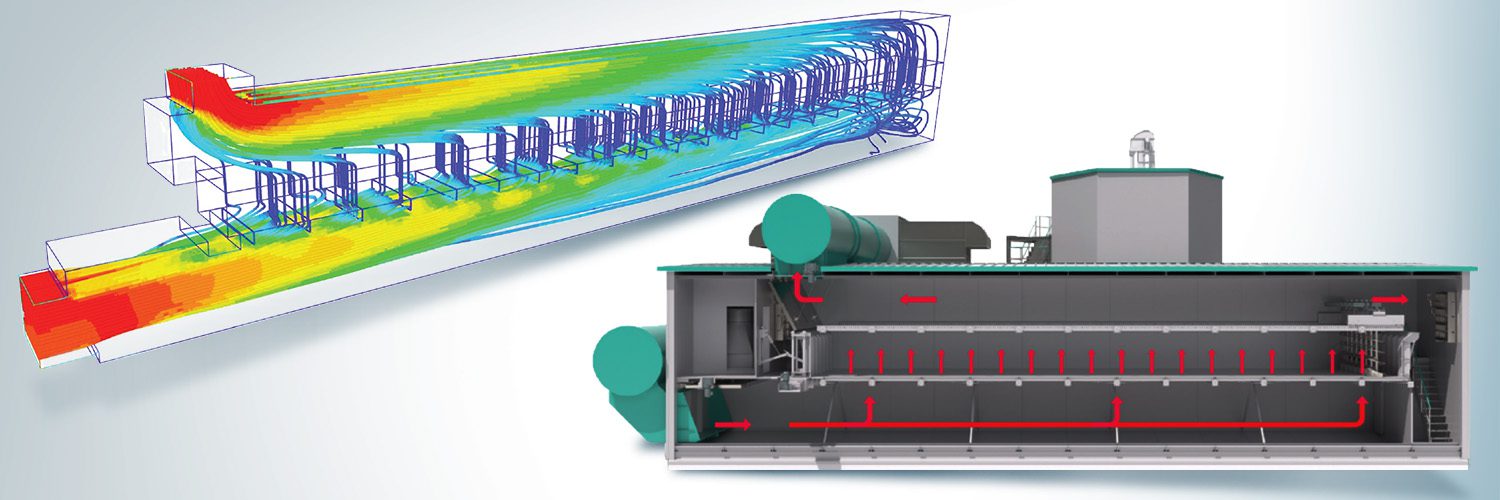

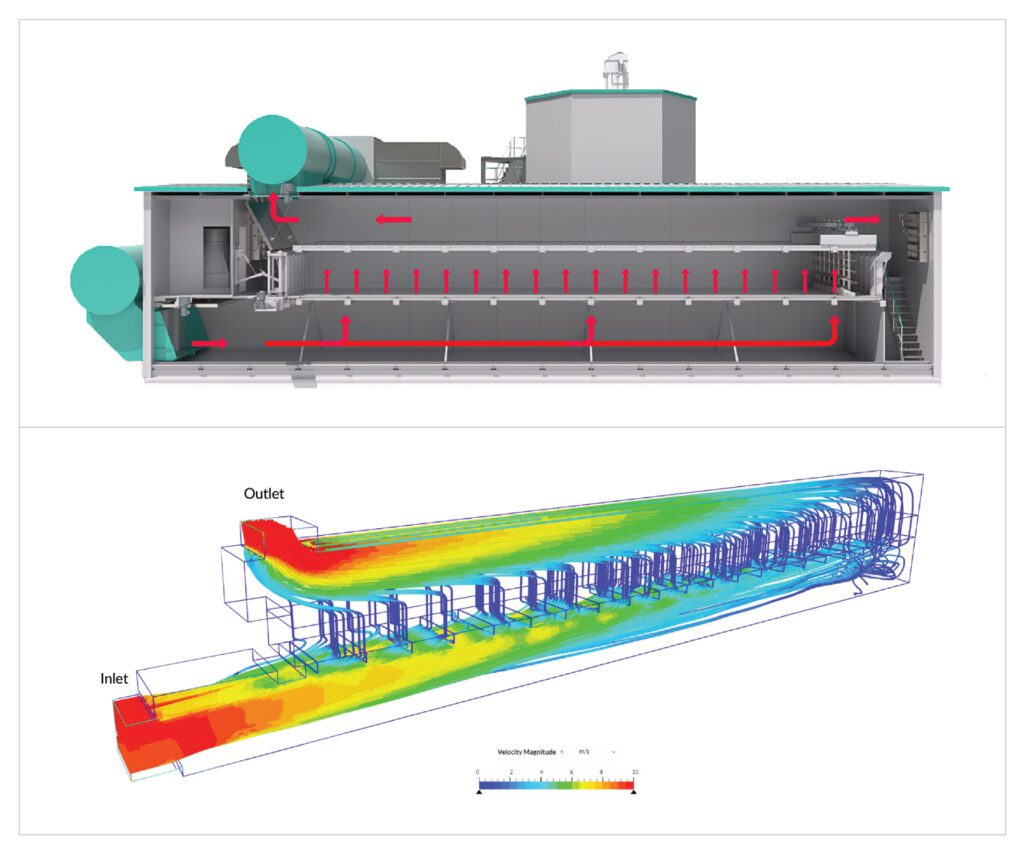

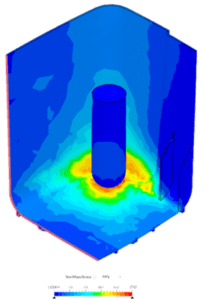

Flow simulations are performed on an industrial-scale malting facility. CFD flow simulation through a standardized modular malting plant with annual throughput of between 1,000 tons and 17,000 tons of malt is shown in the image below. CFD is used to model the fluid flow and optimize flow speeds and pressure losses throughout the process. Simulation allowed them to scale the malting plant without costly and time-consuming pilot plants of different sizes being built and tested.

SimScale is easy-to-use with great support, such that a simulation newbie was able to study 60 different design variants in only 2 weeks, which eventually allowed to gain confidence for the scale-up.

Folke Schmidt

R&D Team Manager in Grain Quality at Bühler

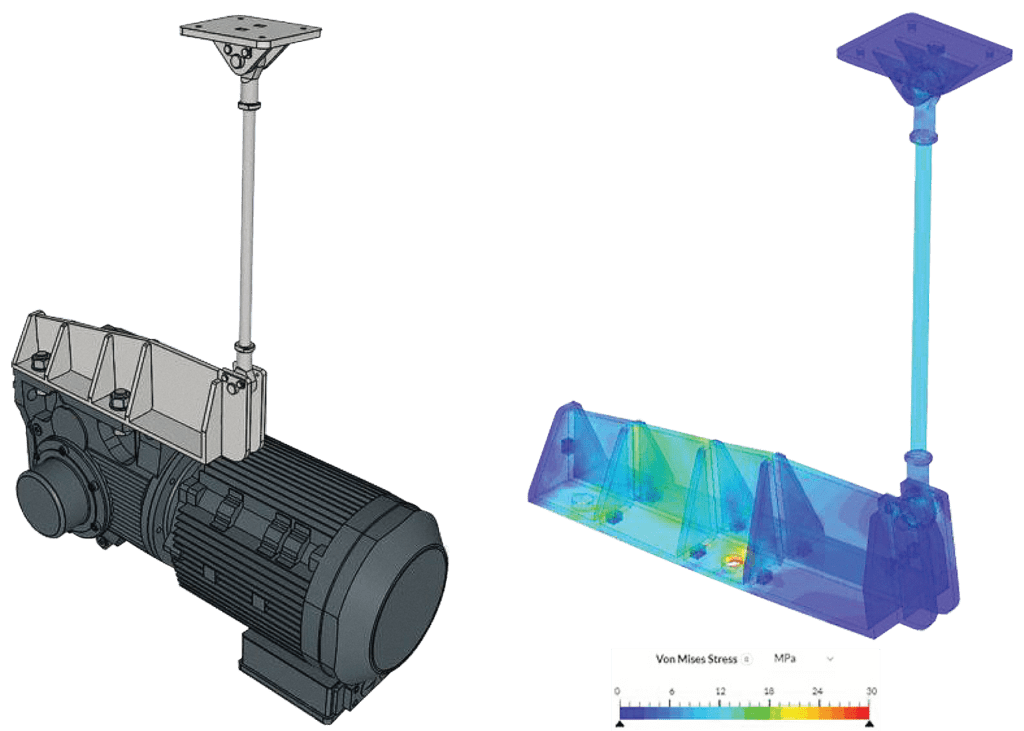

Another example of where decentralized simulation use allows verification of small customizations quickly is the simple structural analysis now available to all engineers. Customer adaptations can be checked by the design engineer directly, as in this case where structural FEA analysis of a motor plate is used to illustrate Von Mises stresses. The impact of vibration is also simulated to check for any safety issues from vibration.

With SimScale we can now verify customized parts and assemblies on our own without detouring to (external) simulation analysts.

Markus Huber

Mechanical Development Engineer in Grain Quality at Bühler

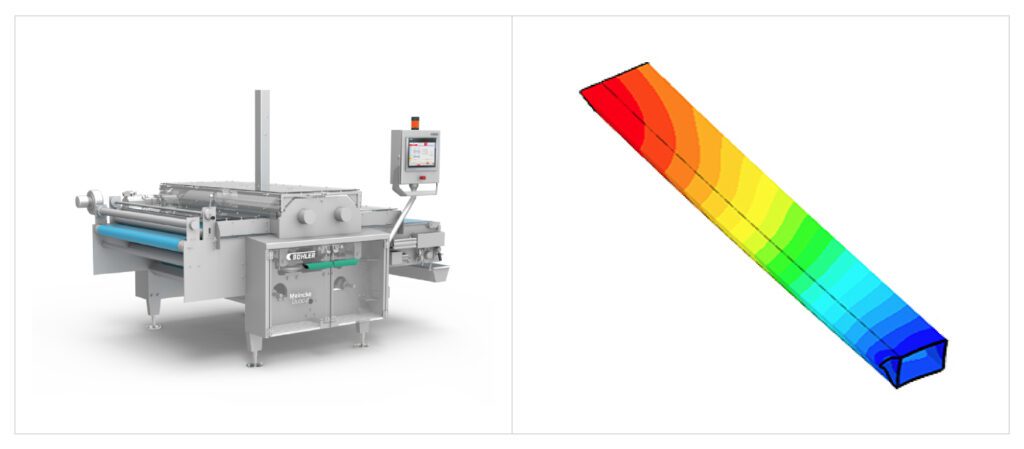

A roller cutting machine shown in the image below is optimized for hygienic and efficient performance. The cutting knife is simulated to reduce its weight, improve hygiene, and maintain strength using structural FEA to evaluate deformation and stresses under various loads and operating conditions.

SimScale made it possible to test 19 possible design improvements (quickly) and choose the best options. In addition, it is easy to copy, edit, and share models.

Anton Auszerlechner

Deputy Manager Feed and Forming Cracker in Consumer Foods at Bühler

For Bühler, deploying advanced analysis capabilities at an enterprise level at scale has become straightforward. Engineers can use simulation in a web browser, on-demand, on a daily, weekly, or monthly basis without any capacity limitations. This ability also enables them to scale usage when needed. Observations from working with other similar-sized engineering firms show a clear benefit of using simulation across the business. Quantifying the business benefits of a robust and embedded simulation strategy shows several important outcomes:

SimScale allowed us to virtually test and compare tens of different design ideas and, hence, understand the key influencing factors.

Patrick Rohrer

Mechanical Development Engineer in Value Nutrition at Bühler

Sign up for SimScale

and start simulating now