The Alaska Native Tribal Health Consortium (ANTHC) is a non-profit tribal health organization designed to meet the unique health needs of Alaska Native and American Indian people living in Alaska. ANTHC provides the highest quality health services for Alaska Native people at the Alaska Native Medical Center and across Alaska through training, health education, disease prevention, and rural water and sewer construction. ANTHC’s statewide work spans many sectors and services to advance its vision that Alaska Native people are the healthiest people in the world. ANTHC is the largest, most comprehensive tribal health organization in the United States and Alaska’s second-largest health employer with more than 3,000 employees offering an array of health services to people around the nation’s largest state. They are also responsible for environmental and sanitation engineering, providing access to water and sanitation services in rural areas, and maintaining water and air quality.

The Division of Environmental Health and Engineering (DEHE) is the prevention arm of ANTHC. Decades of public health studies available show the close link between the absence of clean water and the increase in respiratory and skin infections. DEHE’s primary role is to address this link to improve the health of rural Alaskans. It is their job to provide clean water and sanitation services to Alaska Natives in rural areas to decrease infectious diseases. Additionally, DEHE regularly invests in research and development with the goal of improving and protecting public health by addressing access to clean water, improving access to healthcare, proper disposal of sewage, improving indoor air quality in arctic homes, energy efficiency, climate change impacts, and sustainable operations.

DEHE has 5 primary core operation areas:

William Fraser (Will), Lead Mechanical Engineer, has been at ANTHC for twenty years. He has 34 years of engineering experience and holds a BA in Physics and BS & MS degrees in Mechanical Engineering. Will also holds the rank of Commander in the US public health service. Over the years, Will has managed the Health Facilities support program, sanitation engineering department, and was one of the founding members of the energy group. He works on many health infrastructure-related water and sewage projects at DEHE with a growing team of 45 engineers.

Will is currently part of the sanitation group that builds water treatment and sewage facilities, and his role includes supporting architects and developers in designing HVAC, energy, and water projects. William is the de-facto Sanitation group R&D team and is continuously looking to improve DEHE’s skills, software tools, and capability.

I found the learning curve for SimScale to be short and within a weekend of use had achieved meaningful results. I especially like the post-processing and visualization tools in SimScale and the technical support is terrific for critical projects whenever I need it. I’m an experienced engineer but I don’t have to be a CFD expert to use SimScale. We are looking more towards thermal and structural analysis in the future and to try out the new multiphase solvers to evaluate critical infrastructure events such as dam failures.

William Fraser

Lead Mechanical Engineer at ANTHC

The DEHE team has a critical role to play, not least because people’s health and lives depend on their work. Engineering simulation tools are used at DEHE, including for HVAC, civil engineering, and water treatment. Common use cases include the design and sizing of water and sewage piping networks in urban and rural communities, sizing water storage tanks, designing water treatment plants, plume flow modeling of sewage effluent into the ocean, and microgrid optimization for the use of recovered heat, solar and wind power. SimScale is applied specifically to fluid flow and thermal analysis problems including:

The water treatment industry often uses water storage tanks as chlorine contact reactors. When this is done, storage level, water temperature, and the contact time for chlorine disinfection must be carefully managed to stay within limits set by state and federal health regulations. Too little chlorine and the water is not sufficiently disinfected, allowing pathogens to grow in the water system. Too much chlorine leads to the creation of chlorinated byproducts in the water that are toxic and carcinogenic.

Water storage tank contact reactor designs are typically based on isothermic CFD modeling performed by the University of Colorado in the early 2000s, which predicts mixing efficiency (baffling factor) based on the tank geometry. Regulatory agencies typically will accept the University of Colorado baffling factors and sometimes will require a tracer study (conducted by adding chloride salt to change the salinity gradient over time) after the system is constructed to ensure performance meets the design intent.

It has been noted for years by DEHE engineers that the tracer studies frequently do not agree with anticipated design results, and the tracer study results can vary dramatically by season and operating temperature. William and his team hypothesized that temperature-induced density gradients within the tank create unanticipated water movement that does not exist in isothermal conditions and set out to qualitatively and quantitatively develop improved models for designing safe and effective chlorine contact reactors.

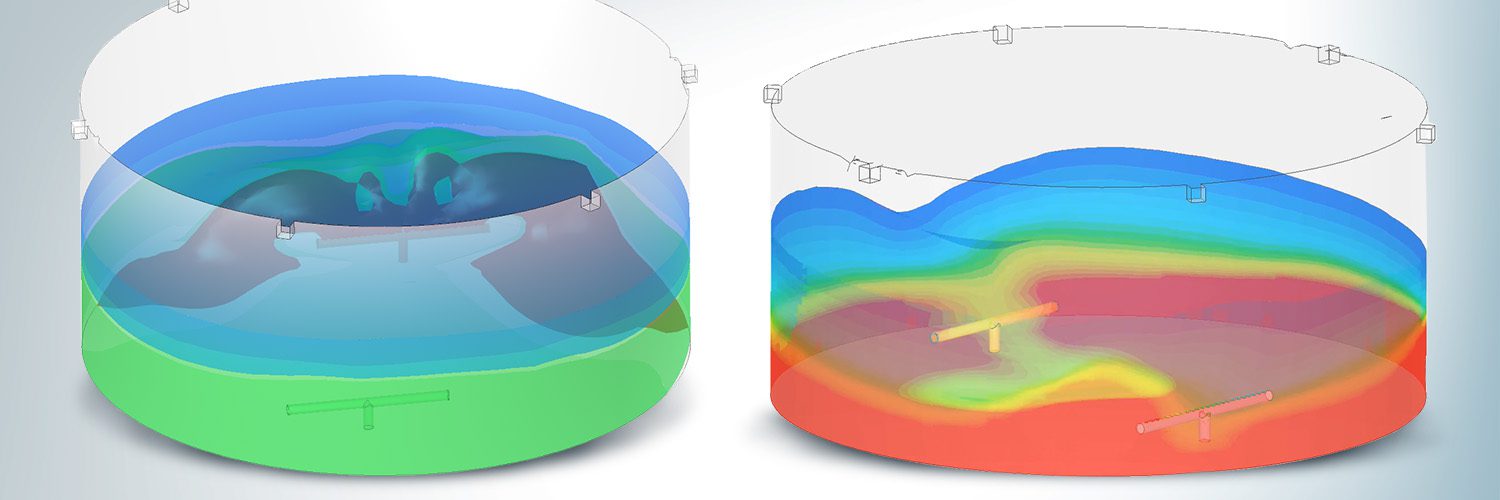

DEHE set out to demonstrate the validity and cost-effectiveness of non-isothermic computational fluid dynamics (CFD) as a tool for improving the design and performance of water storage tanks by first modeling heat loss from water storage tanks to gain an understanding of what the temperature profile inside the tank looked like in cold weather conditions and to refine modeling for heat loss in order to reduce energy consumption. After that work was finished, the team wanted to see if they could improve the baffling factor to be more consistent and reduce temperature dependence to achieve better chlorine-water contact time (CT) performance.

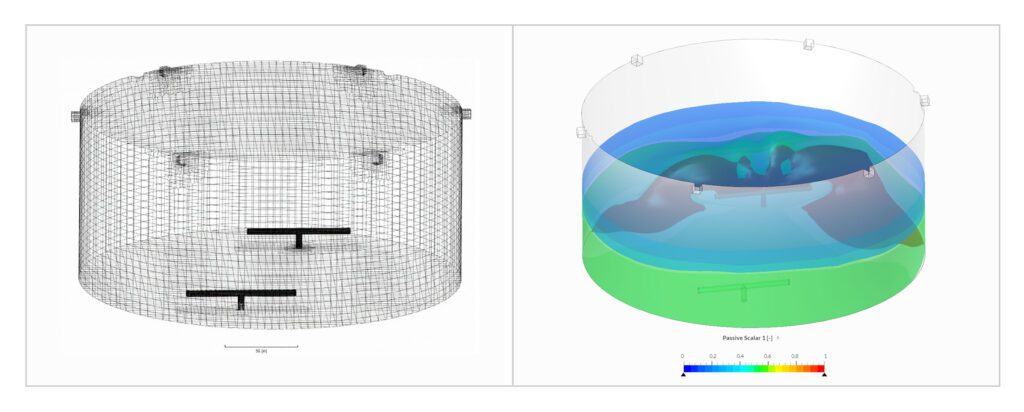

In order to evaluate the quality of the CFD results, the team selected as a case study the Igiugig community water storage tank — a tank that previously had two tracer studies performed at different times of the year and with different inlet piping configurations. The CFD modeling used conditions matching the tracer study conditions so the results could be compared. The team then tried several variations of inlet piping to improve baffling factor performance. The conclusions & recommendations of the tracer studies and CFD modeling demonstrated the significant impact temperature plays in contact time in water storage tanks and the results were presented to water system designers, operators, and regulators at the American Water Works Association (Alaska Branch) annual meeting in May of 2023.

Igiugig is a native community located in southwest Alaska. It is a stunningly beautiful world-class fishing location and in the summer hosts trophy-hunting fishermen from around the world. It is also extremely remote, accessible primarily by small, single-engine airplanes. Construction projects in Igiugig are logistically challenging and extremely expensive, making getting it right the first time essential.

In 2015, a new bolted commercially manufactured water storage tank was constructed in Igiugig. It was permitted for construction with the requirement that a tracer study be performed to confirm performance. That study, performed in February 2016, failed to demonstrate adequate performance of the tank. In 2016, the tank inlet was modified and a second tracer study was performed in June 2016, which met the contact time requirements of the tank. The cost to modify the tank and perform a second tracer study exceeded $150K.

The water storage tank in Igiugig, Alaska has a 50,000-gallon capacity and has an inlet and outlet on opposite sides. The initial tracer study was conducted at a water level of 10 feet and an anticipated baffling factor of 0.1. The measured baffling factor was 0.042 and did not meet regulatory requirements. The design engineer for the project then used a hose and a large bucket of water to try alternative designs to develop the revised design, which was then implemented and passed the 2nd tracer study evaluation.

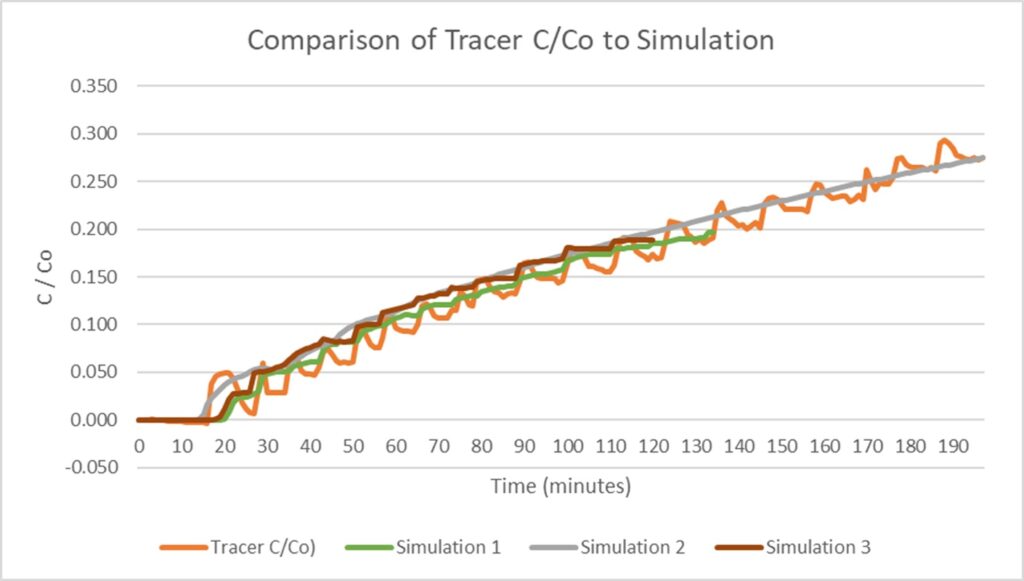

The SimScale model of the original water storage tank had three boundary conditions applied to test the model setup and calculate the baffling factor. The field tracer study results matched closely to those predicted using SimScale:

| Test | Contact Time | Baffling Factor |

|---|---|---|

| Original Model Tracer Study | 52 minutes | 0.042 |

| Simulation 1 | 57.5 minutes | 0.047 |

| Simulation 2 | 50.5 minutes | 0.041 |

| Simulation 3 | 53 minutes | 0.043 |

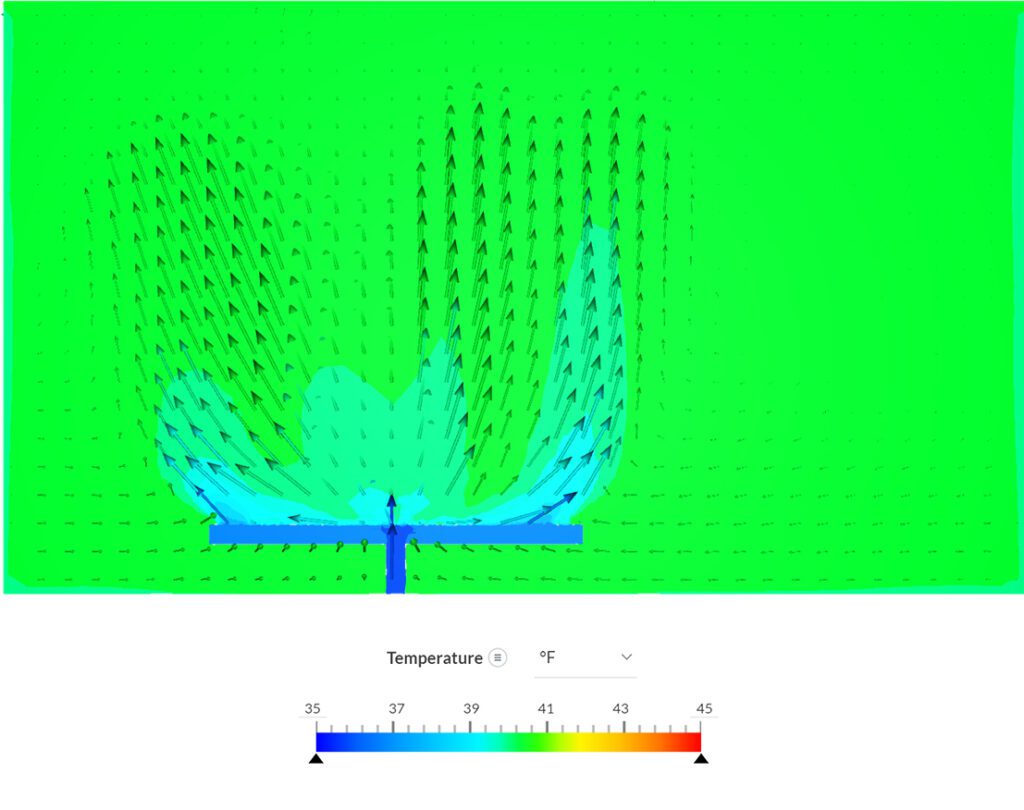

CFD was used to compare the inlet tank conditions for isothermal and non-isothermal conditions. The results show a significant difference in internal conditions that would then propagate and impact water-chlorine contact time.

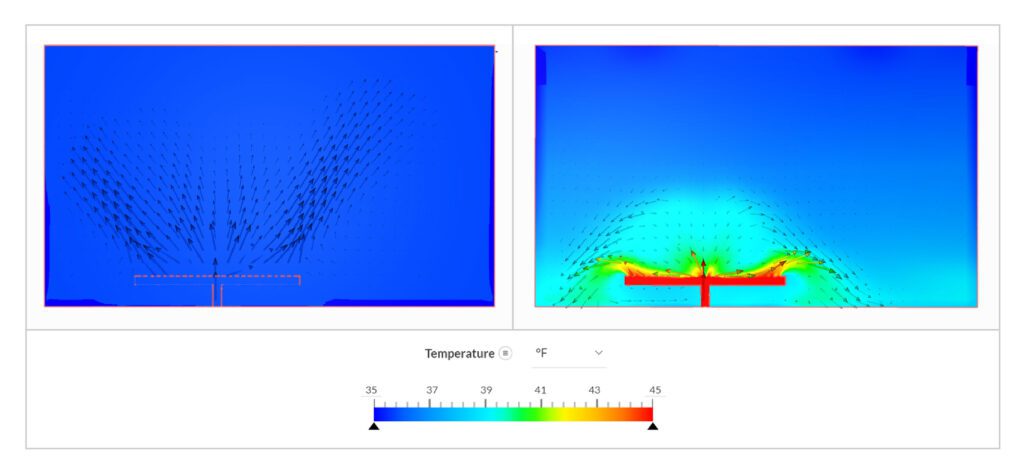

The team then ran another set of simulations where the tank was warmer than the inlet water temperature (non-isothermal) as this condition can exist naturally or when the stored water is preheated. Natural water supply sources in Alaska can be near freezing much of the year whereas the water stored in the tank is somewhat isolated and also stores thermal energy.

The results showed that standard isothermal condition assumptions are not valid and that the disparity between tracer results and isothermal assumptions is too large to ignore. This meant the tank described in this case study was not correctly designed for optimal performance. The initial tracer study was conducted on-site at great cost as engineers with test equipment had to fly to remote areas for testing.

The tank was subsequently modified and a second tracer test was run. The major changes to tank design revolved around the water inlet configuration this time being a 1-inch nozzle placed 10 feet above the tank base height inside the tank.

This tank configuration led to improved tank performance as the jet entrainment led to improved thermal mixing within the tank (no plug flow) and yielded a baffling factor = 0.10 – 0.11. Some initial conclusions and recommendations have been made based on this set of simulations:

CFD has brought a higher level of confidence to the team and they are expanding the use of SimScale moving forward to evaluate other phenomena such as dam failure and wastewater flow.

Incoming water quality can vary by time of year and weather, therefore the amount of chlorine required to achieve disinfection can also vary. We want to minimize the amount of chlorine added in the water storage tank but still achieve a safe chlorine concentration. We use SimScale to design the water storage tanks to have as consistent reaction time as possible and make sure we hit the minimum value of chlorine required.

William Fraser

Lead Mechanical Engineer at ANTHC

The state of Alaska typically requires a tracer test when storage tanks are used as Chlorine contact reactors, which typically costs around $30,000 USD. If the test fails, the tank must be modified, and the test performed again, with costs that can easily exceed $100,000 USD. Now we can use CFD first at the design stage to validate performance and make the tank model work for the first time. Because of our work, it’s now standard practice at DEHE to use CFD on these types of projects. Typically, we can perform the analysis with SimScale in four to eight hours with a high degree of confidence in the results.

William Fraser

Lead Mechanical Engineer at ANTHC

Sign up for SimScale

and start simulating now