Fusion Modulair is a leading indoor climate engineering firm and professional services company that designs, develops, manufactures, and installs an advanced purpose-built range of modular solutions for air conditioning large-volume spaces. With a history that spans 20 years, Fusion has pioneered the modular approach, assisting clients in achieving sustainability targets through dematerialization, optimized solution architecture, and leading performance. Its systems operate in almost any climate and are an integral part of projects seeking LEED, Green Star, or NABERS building ratings and certification. Fusion invests continuously in R&D and innovation, which has resulted in numerous patents, registered designs, and the development of the industry’s foremost solutions for high energy efficiency temperature control for large volume spaces. Engineering simulation is at the heart of innovation at Fusion.

The increasing manifestations of a changing climate are reshaping building designs and HVAC strategies. A pressing concern emerging from this shift is safeguarding occupants from extreme thermal impacts, chiefly the variations of heat and cold burden. These variations have profound implications for workplace health and safety. This comprehensive case study delves into the indispensability of simulation tools, such as computational fluid dynamics (CFD) simulations, using SimScale to evaluate and guarantee the thermal comfort of building occupants. Fusion Modulair utilizes these tools in designing their industry-leading climate control solutions that provide indoor thermal comfort in any climatic conditions.

It is not physically possible to do this type of testing and verification in real life, a building of this size cannot be physically tested to determine an optimized HVAC solution, hence typically in the HVAC industry rework and fixes are required after completion of the HVAC install in a project as the design has not been verified before the installation occurred. SimScale provides the opportunity to assess a design and gain a better understanding of the proposed solution before any onsite works occur, this aids in reduced onsite costs, reduced initial capital costs, reduced post-install rework, and addresses poor performance of HVAC systems.

Ken Thomson

Senior Engineer, Energy, HVAC and ESD Services at Fusion Modulair

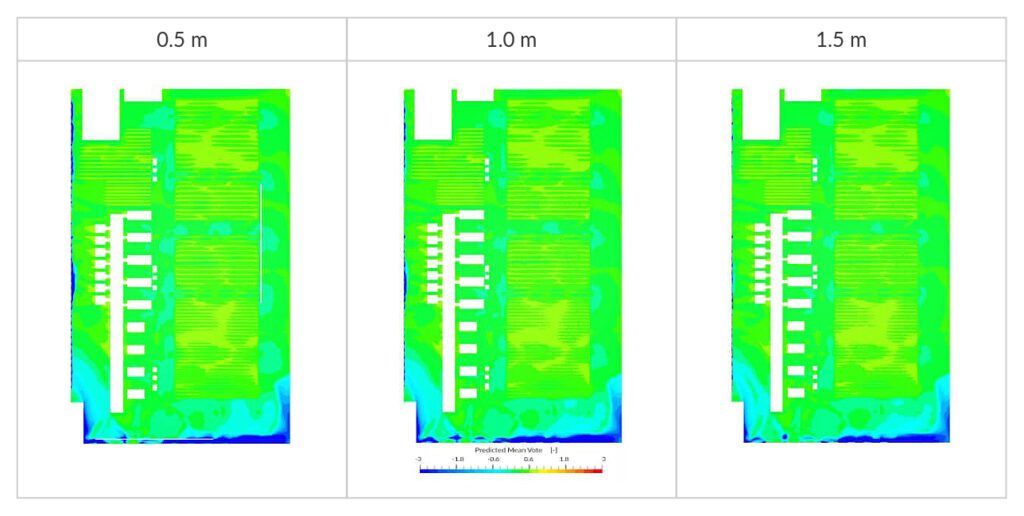

Working in extreme temperatures (hot or cold) can overwhelm the body’s internal temperature control system. When the body cannot warm or cool itself, heat or cold-related stress can result. Air quality and the internal thermal environment of a building directly impact occupants’ health, safety, and productivity. This is where quantifiable measures of thermal comfort, such as the Predicted Mean Vote (PMV) and Predicted Percentage of Dissatisfied (PPD), become instrumental. Balancing PMV and curtailing PPD is paramount to ensuring comfort. In the contemporary landscape, buildings devoid of air-conditioning systems, be they naturally ventilated or mechanically ventilated, face a heightened risk profile due to the unpredictable effects of climate. In such facilities, ensuring a thermally comfortable environment becomes not just challenging but also critical for maintaining workplace health and safety standards.

Increasingly, indoor thermal comfort-based risk assessments are required with a corresponding set of procedures and practices for safely working in temperature extremes. Both heat and cold stress can cause multiple occupant health and productivity issues.

Common heat-related effects, for example, include:

End clients require the prediction of PMV and PPD and the draft risk associated with heat burden assessments. Compliance with various standards including ASHRAE 62 and 55 standards must also be demonstrated.

One of the practical solutions for combating heat stress inside buildings is using appropriate engineering controls. For employees working indoors, the best way to prevent heat-related illness is to make the work environment cooler. Where and if possible, use air conditioning to cool the work area. Alternatively, increase the general ventilation as much as possible by opening windows or doors if the outside temperature permits. When available, use fans to aid in increasing air movement. Although this sounds simple, it needs a precise set of equipment, controls, sizing, and design intent to make it a reality.

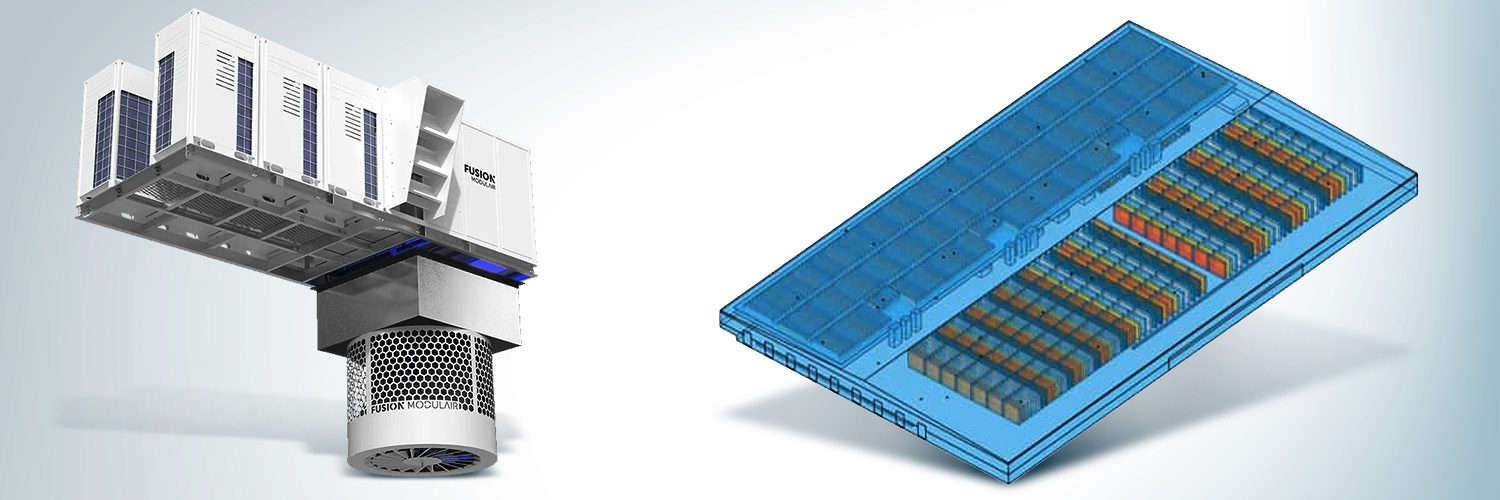

Fusion Modulair’s patented hardware is purpose-built in a factory as a complete and modular HVAC product and redefines thermal comfort. One of the system’s standout feature is its capacity to cater to vast spaces, all from a singular diffuser module. The overarching goal is uniform temperatures, ensuring a holistic, draft-free, and comfortable environment for the occupants. A hallmark of the system is its integration with high-induction, variable volume, and variable direction motorized swirl diffusion modules, exclusively manufactured for Fusion Modulair by world-renowned air diffusion solution company, Smartemp. These modules are meticulously engineered to provide temperature uniformity in a three-dimensional space, irrespective of external climatic variations.

Using traditional simulation software has presented some challenges in this complex setup, especially when trying to model air velocity boundary conditions at multiple locations using a CSV input file to represent the X/Y/Z position and velocity of a complex diffuser. The combination of SimScale and ParaView has allowed this process to occur and gives a much greater level of confidence and accuracy to the simulation results than using approximated boundary conditions that are typical of other CFD simulations.

Ken Thomson

Senior Engineer, Energy, HVAC and ESD Services at Fusion Modulair

Developing the correct boundary conditions to represent the air diffusion requires detailed knowledge and real-world test results. Typically, due to a lack of available data, some consultant-derived CFD simulations use approximations to represent the boundary conditions, and hence obtain final results that do not reflect the real performance of the air diffusion. This can result in the predictive simulations being inaccurate, and hence consultant advice being based on the data from these simulations.

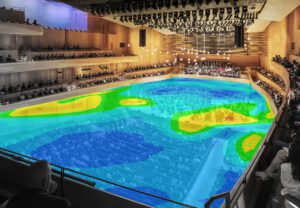

To validate and showcase the effectiveness of Fusion Modulair’s systems, CFD simulations, powered by SimScale, were deployed for the assessment of multiple design options with regards to the ‘heat burden effects’ of the proposed climate control or HVAC design scenarios for this building. These simulations are adept at rendering a visual and analytical representation of airflow patterns, temperature gradients, and other vital metrics within a building’s design. The simulation process was as follows:

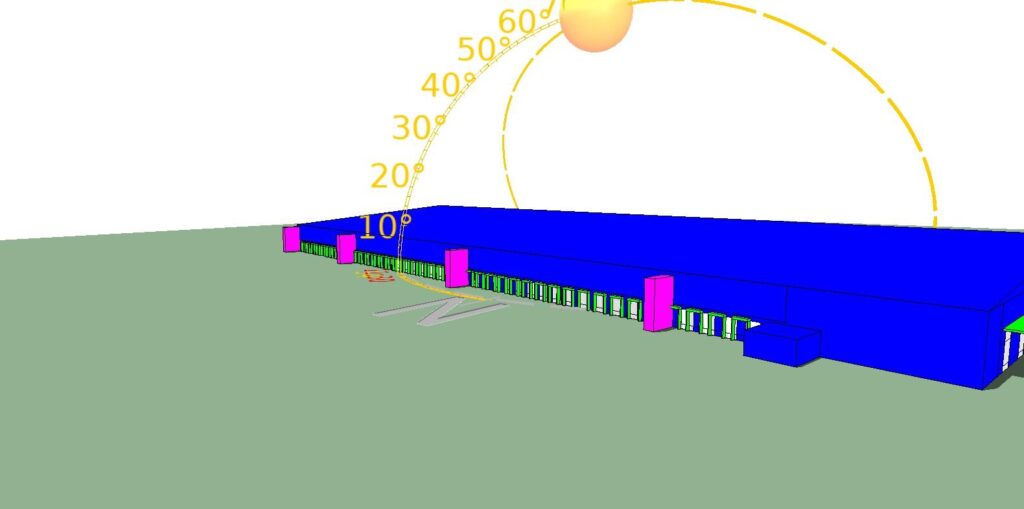

Using a comparative methodology approach, various building design scenarios were developed for a 55,000 m2 warehouse building in Australia (Climate Zone 6, BCA Classification 7). Each one is briefly described below:

The scenarios spanned three building types with four differing HVAC solutions and for each scenario, ambient winter (16℃ and 20℃) and summer (24℃, 26℃, and 29℃) conditions were simulated.

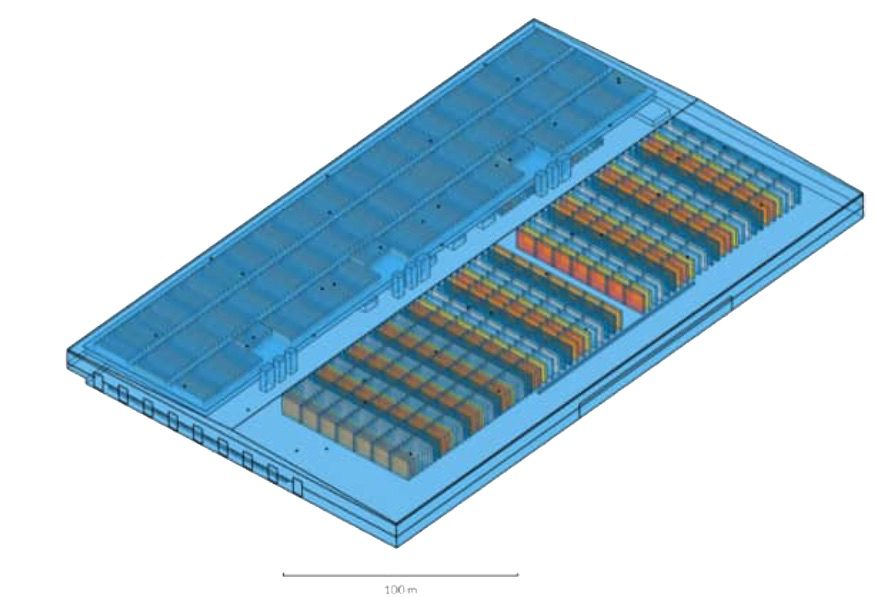

The building contains significant shelving and racking used to store stock and material. A porous media boundary condition is used to represent the racking system, as this will allow for the simulation to approximate the airflow into and around the racking. The simulation needs to use the porous media approximation to reduce the CAD and mesh complexity, which saves computational time and expense.

A combination of Fusion systems and high-volume low-speed fans (HVLS) are proposed to support airflow and achieve the required thermal comfort conditions inside the building. The Fusion solution as in scenario 1 included a VAV system composed of:

To simulate the yearly data needed for inputs to the CFD simulations, thermal modeling was employed using the IES-Virtual Environment (VE) software tool. This provides data on the internal surface temperatures and estimates of the internal air temperatures. The model assumes a completely uniform and homogenous air distribution throughout the entire occupied space. The data obtained from the IES-VE models provides for the following analysis:

Thermal modeling software is generally limited to a maximum airflow for PMV and PPD assessment of 1 m/s. Based on the CFD studies of the mechanical ventilation solution, which show maximum airflow eddies occurring in some locations at 6.7 m/s, the PMV and PPD results from these other software tools cannot be relied upon when considering a natural or mechanically ventilated warehouse, the use of CFD becomes critical in these instances.

The simulation outcomes across multiple scenarios clearly illustrated the benefits of a well-designed and sized HVAC system, including:

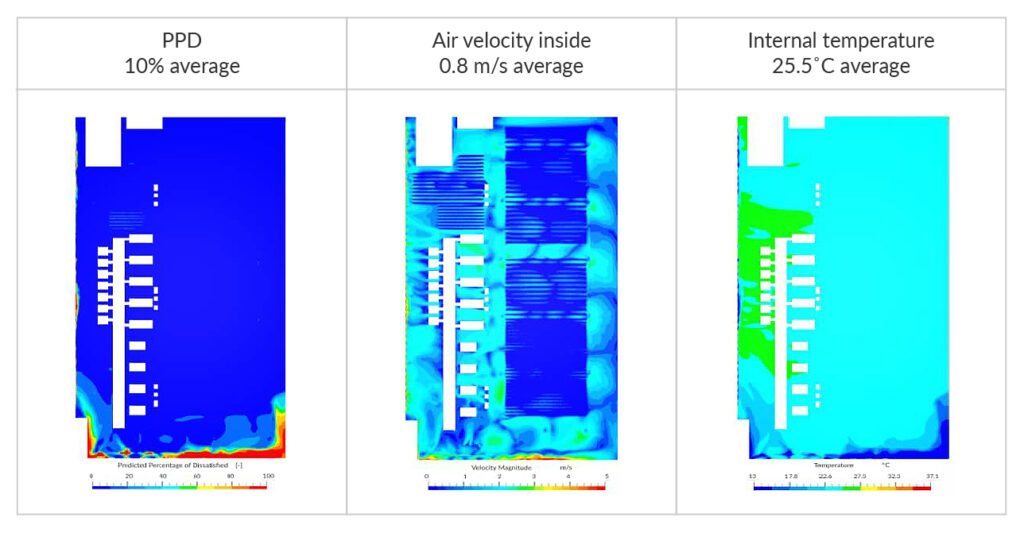

A summary of Scenario 1 is shown below. This is the scenario with a full Fusion Modulair solution and HVLS fans for improved thermal comfort and improved energy efficiency. In summer conditions, the Fusion system provides 210,000 L/s of airflow assuming all rapid doors are closed and with half internal loads active with a 0.25 ACH infiltration rate. At the summer design simulation of an overall ambient condition at 37°C, and humidity of 32.2.% RH at the peak time of day, Fusion’s system maintains good thermal comfort internally showing an average PMV of -0.1, an average PPD of 10%, and an internal average temperature of 25.5°C.

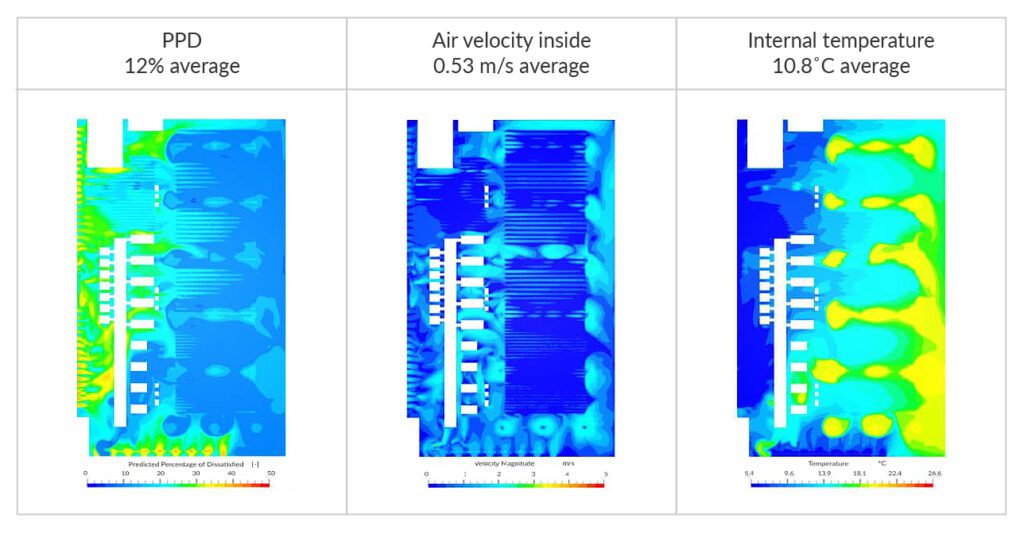

Considering a different scenario when the Fusion system is not using its reverse cycle heat pump capability but is using the economy mode or outside air ventilation application, which is comparable to a mechanical ventilation system, at an airflow supply rate or mechanical exhaust flow rate of 100,000 L/s with winter ambient conditions of 5.4°C and humidity at 73% RH, the modeled thermal comfort for this economy mode or mechanical ventilation is a bit below the required internal temperatures the client would expect. However, the benefit of the Fusion solution is that it can resolve this poor thermal comfort performance of a mechanical ventilation system. Fusion systems can provide free cooling, full outside air with trim heating, or full heating capacity via the Fusion systems reverse cycle heat pump capability pushing warm air down to floor level, even though the diffuser is located at 12m above the floor level. This will provide warm air to the occupied spaces and result in internal air temperatures of 16°C to 19°C or higher when required. Fusion Modulair has used live testing, CFD, and onsite measurements to verify this heating performance. of having the Fusion HVAC units.

The technical capabilities and serious grunt of the SimScale software solution allowed Fusion Modulair to complete over 22,000 core hours of computational processing time, in a 3-week window on this building with 55,000 m2 floor area and 765,000 m3 volume. The meshing capacities of the SimScale software allowed us to build a model using 47 million cells and obtain results within 10 hours, including representing the internal racking systems using a porous mesh, and simulating other internal objects in and around where people are located.

Ken Thomson

Senior Engineer, Energy, HVAC and ESD Services at Fusion Modulair

While buildings without air-conditioning grapple with the oscillations of climate change, Fusion Modulair’s systems are a good example of how technology can be harnessed to counter these challenges whilst meeting comfort and energy efficiency requirements. The result is a promising pathway to architecting buildings that are resilient, environmentally attuned, and occupant-centric.

Ken Thomson has been in the building industry for over 30 years and has built up skills within HVAC&R, energy efficiency, building physics, energy monitoring, facilities management, asset management systems, and use of energy and CFD software for understanding HVAC system impacts in detail. Ken is highly proficient in the use of the IES-VE energy modeling software packages, SimScale CFD software, and the development of energy efficiency savings projects. Ken has experience across all building sectors including industrial, warehousing, commercial, retail, defense, and healthcare.

Sign up for SimScale

and start simulating now