Documentation

The aim of this test case is to validate the following parameters of incompressible steady-state laminar fluid flow through a pipe:

The simulation results of SimScale were compared to the analytical results obtained using the Hagen-Poiseuille equations\(^1\). The mesh was created with the Hex-dominant Automatic algorithm on the SimScale platform.

A straight cylindrical pipe was chosen as the flow domain (see Figure 1). Faces A, B, and C represent the inlet, wall, and outlet respectively.

| Dimension | Length | Diameter |

|---|---|---|

| Value \([m]\) | 1 | 0.01 |

Tool Type: OpenFOAM®

Analysis Type: Incompressible steady-state analysis.

Turbulence Model: Laminar flow

Mesh and Element Types:

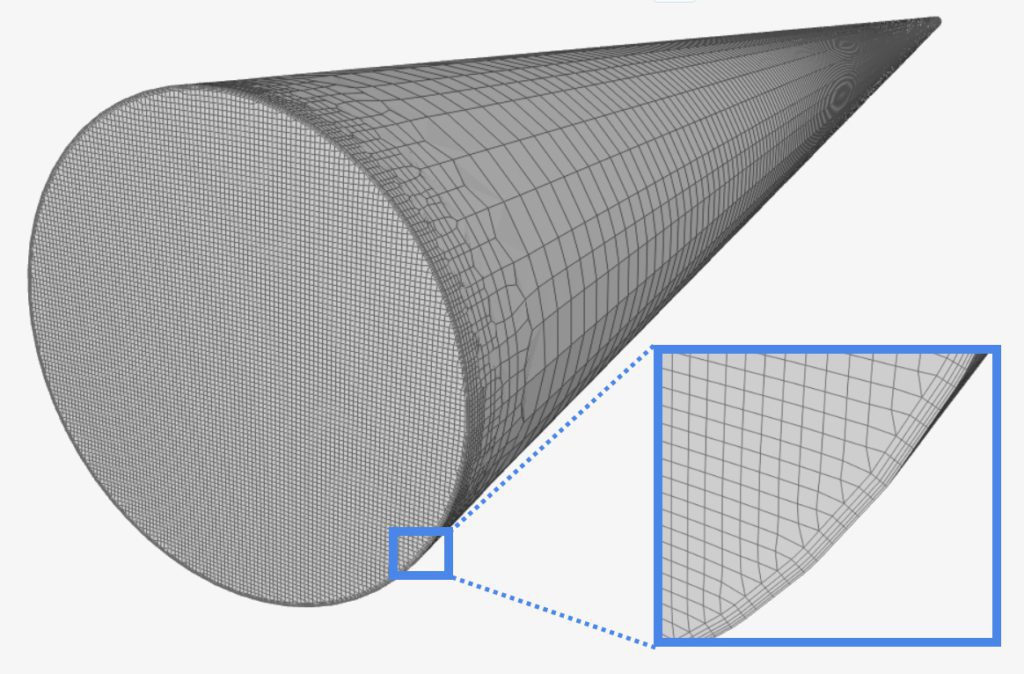

Three structured hexahedral meshes are generated on the SimScale platform using the Hex-dominant Automatic algorithm (see Figure 2). The meshes are gradually refined with a growth rate of 1.25. Later, these meshes are used to verify the mesh independence of the results.

Cell size at the inlet face is smaller than in the other regions. The purpose of this extra measure is to capture the parabolic velocity assignment at the inlet. This topic will be explained in more detail in the next section.

The global cell size and refinement sizes are defined as follows:

| Mesh Name | Global Cell Size \([m]\) | Surface Refinement – Cylindrical Surface \([m]\) | Surface Refinement – Inlet Surface \([m]\) | Number of cells [M] |

|---|---|---|---|---|

| Coarse Mesh | 0.0016 | 8.00E-04 | 1.00E-04 | 0.435 |

| Moderate Mesh | 1.12E-03 | 5.60E-04 | 7.00E-05 | 0.837 |

| Fine Mesh | 7.84E-04 | 3.92E-04 | 4.90E-05 | 1.700 |

Fluid:

Boundary Conditions:

One of the parameters of interest, which is the topic of this validation case, is the pressure drop through the pipe. Above all, the Hagen–Poiseuille equation considers the flow at the inlet to be fully developed. There are two common CFD methods to generate a fully developed flow:

The first method is impractical since it will require a significantly higher mesh count and so the computation resources. Therefore, the parabolic velocity input option is preferred in this project.

The parabolic velocity profile through a circular pipe in a laminar flow is approximated as follows:

$$ u_z = u_{z\ max} (1-{r^2 \over R^2}) $$

$$ u_ {z\ max} = 2 \ u_{z\ avg} $$

where \( u_z \) is the z-component of the velocity along the axis, \(u_{z\ avg}\) is the average inlet velocity, \(u_{z\ max}\) is the maximum velocity that occurs at the centerline, \(r\) is the radial distance from the centerline, and \(R\) is the radius of the circular pipe\(^2\). For instance, a parabolic velocity profile in a circular pipe is illustrated in Figure 3.

The following boundary conditions are applied to the corresponding pipe surfaces:

| Face | Boundary type | Value |

| Inlet (A) | Velocity inlet | Fixed value of \(2 \times 0.1 \times (1-(((x)^2+(z)^2)^{0.5/0.005})^2)\) \(m/s\) in the y-direction |

| Outlet (C) | Pressure outlet | Fixed value of 0 \(Pa\) |

| Wall (B) | Wall | No-slip |

Pressure drop results per mesh are summarized in Table 4:

| Mesh Name | Number of cells [M] | Pressure Drop \([Pa]\) |

|---|---|---|

| Coarse Mesh | 0.435 | 32.192 |

| Moderate Mesh | 0.837 | 32.156 |

| Fine Mesh | 1.700 | 31.993 |

Pressure results change less than 1% between the meshes. Although the coarse mesh result seems reasonable, fine mesh results must be more accurate. Therefore, the results of the fine mesh are presented in this study.

The analytical solution gives us the following equations for maximum axial velocity, pressure drop and developed radial velocity profile:

$$u_{z \ max} = 2u_{z \ avg}$$

$$\Delta P = \frac{128}{\pi} \frac{\mu L}{D^4} Q $$

$$u_z = -\frac{1}{4\mu} \frac{\partial p}{\partial z}(R^2 – r^2)$$

where,

A comparison of the velocity and pressure drop obtained with SimScale with analytical results is given in Figures 4A, 4B, and 4C. Figure 4A shows the developed radial velocity profile at the inlet and the outlet.

The variation of the axial velocity along the center-line:

The pressure drop along the pipe:

References

Last updated: September 24th, 2021

We appreciate and value your feedback.

Sign up for SimScale

and start simulating now