Documentation

This standard documentation covers what is mesh quality and why it’s important. Before starting to read this document, we strongly recommend checking out the following articles:

As mentioned in the mesh article, a mesh is the discretization of geometry into individual elements. Since the mesh is an approximation of the actual geometry, the mesh density and quality have a significant influence on the accuracy and stability of a simulation.

The purpose of mesh quality metrics is to assess the suitability of a discrete computational domain (Mesh) for simulations. A mesh is usually considered to be of higher quality compared to another mesh if it improves at least one of the most important simulation properties; Time to convergence, stability or accuracy without affecting the others negatively.

We measure the mesh quality, using a set of quality metrics. The quality metrics determine how far we are from an ideal cell shape. Below, you will see some mesh quality metrics used in SimScale.

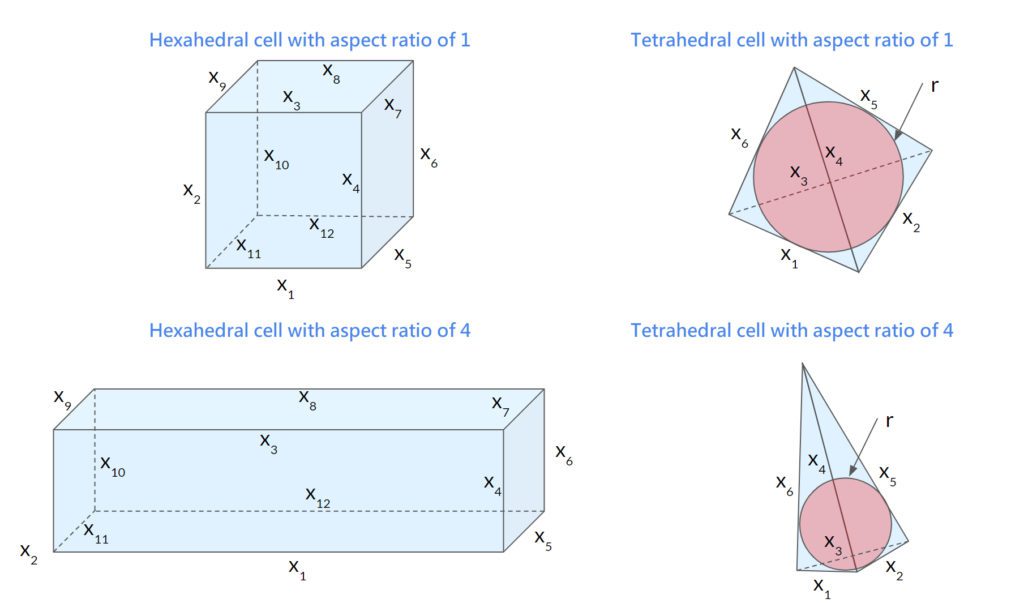

Briefly, the aspect ratio is the ratio of a cell’s longest length to the shortest length. The ideal aspect ratio is 1. The smaller it is, the higher the quality of an element is. The calculation method varies by the cell type as follows:

Hexahedral cell aspect ratio: Ratio of maximum edge length to the minimum edge length.

$$ AspectRatio = \frac{max(x_1, x_2, …, x_{12})}{min(x_1, x_2, …, x_{12})} $$

Tetrahedral cell aspect ratio: It’s correlated between the maximum edge length and radius of the cell’s internal sphere.

$$ AspectRatio = \frac{max(x_1, x_2, …, x_6)}{2 \cdot \sqrt 6 \cdot r} $$

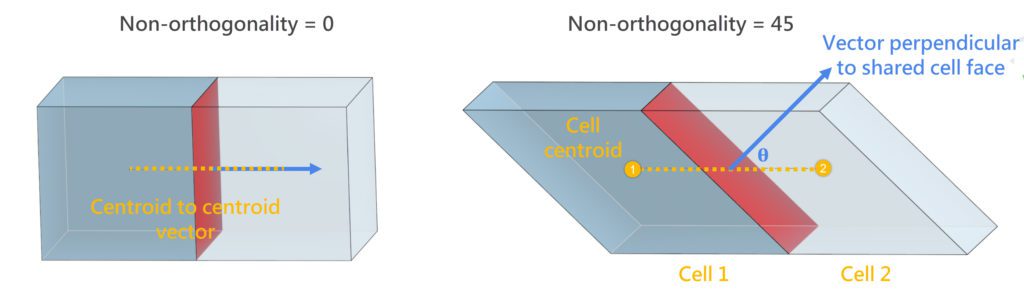

Non-orthogonality is the angle between the vector connecting two adjacent cell centers and the normal of the face shared by these cells. The range of non-orthogonality is between 0 (ideal) and 90 (worst). 0 indicates the mesh being orthogonal. Two perfect hexes aligned with each other have non-orthogonality equal to 0.

A high level of non-orthogonality should be avoided since it causes numerical instability. As a result, the simulations with higher non-orthogonality either take longer to converge, or even diverge.

It is recommended to keep the non-orthogonality below 70. Please consider improving the mesh if the non-orthogonality is above 80. Simulations with the meshes with maximum non-orthogonality above 85 likely diverge.

Volume ratio is the ratio of the volumes of the adjacent cells. Consider two adjacent cells with volumes of \(V_1\) and \(V_2\). The volume ratio is computed as follows:

$$ Volume\ ratio = \frac{max(V_1, V_2)}{min(V_1, V_2)} $$

In reality, a single cell is surrounded by multiple neighbor cells. Since there are multiple volume ratios, we consider the maximum volume ratio as the cell’s volume ratio.

$$ Volume\ ratio_i = max( Volume\ ratio_{j=1}, Volume\ ratio_{j=2},…, Volume\ ratio_{j=n}) $$

The ideal volume ratio is 1. The smaller it is, the higher the quality of an element is.

Tet edge ratio is the ratio between the longest and the shortest edges. This quality metric is only available for the tetrahedral cells. Considering the edge lengths of a cell represented by x, the tet edge ratio is then computed as follows:

$$ Tet edge ratio = \frac{max(x_1, x_2, … x_6)}{min(x_1, x_2, … x_6) } $$

Skewness is the deviation between the optimal cell size to the existing cell size. The range of skewness is between 0 (ideal) to 1 (worst). Highly skewed cells are not preferred due to the poor accuracy they cause within the interpolated regions. The calculation method varies by the cell type as follows:

Hexahedral cell skewness: It measures the deviation between the vertex angles of face pairs of a hexahedron and the ideal vertex angle of 90 degrees. Simply the maximum and minimum angles inside the hexahedron are found and assigned in the following equation:

$$ Skewness =max( \frac{\theta_{max}-90}{180-90}, \frac{\ 90- \theta_{min}}{90} ) $$

Tetrahedral cell skewness: Ratio of deviation between the ideal volume and the cell volume to the ideal volume. The ideal volume of a tetrahedral cell is calculated as follows:

$$ V_{ideal}= \frac{8 \cdot \sqrt 3 \cdot R^3}{27} $$

It’s correlated between the maximum edge length and radius of the cell’s external sphere.

$$ Skewness = \frac{V_{ideal}-V_{cell}}{V_{ideal}} $$

It is recommended to keep the maximum skewness below 0.5. Please consider improving the mesh if the average skewness is above 0.33 or maximum skewness is above 0.85.

Hexahedral cell quadMaxAngle is the maximum of the angles between neighboring cell edges. The normal range varies between 90 (ideal) to 180 (worst). The acceptable range is 90 to 135.

Tetrahedral cell triMaxAngle is the maximum of the angles between neighboring cell edges. The normal range varies between 60 (ideal) to 180 (worst).

Tetrahedral cell triMinAngle is the minimum of the angles between neighboring cell edges. The normal range varies between 0 (ideal) to 60 (worst).

There are mainly two applications for this type of quality assessment:

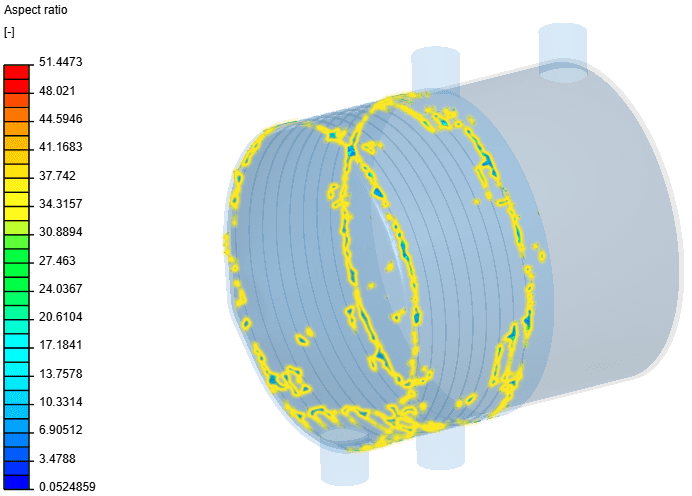

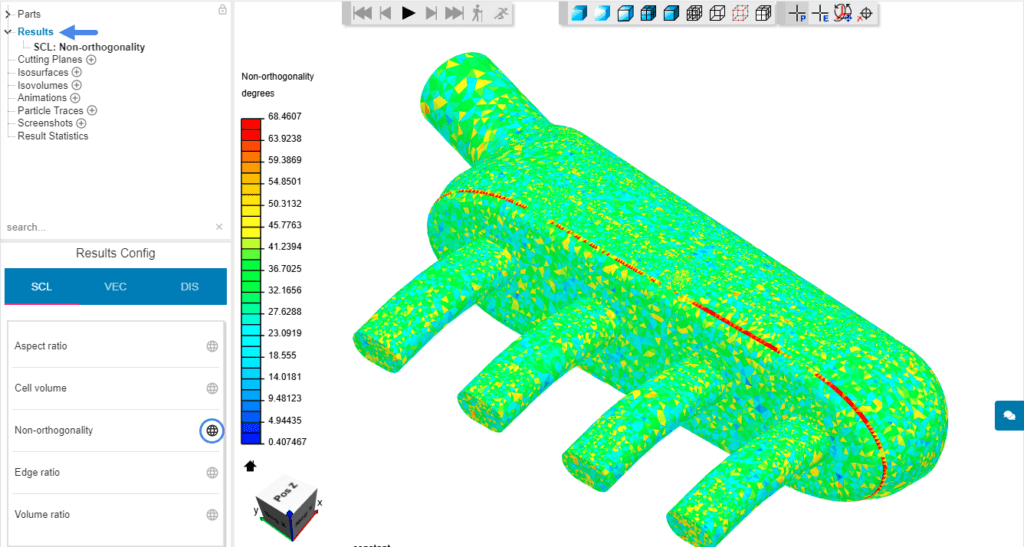

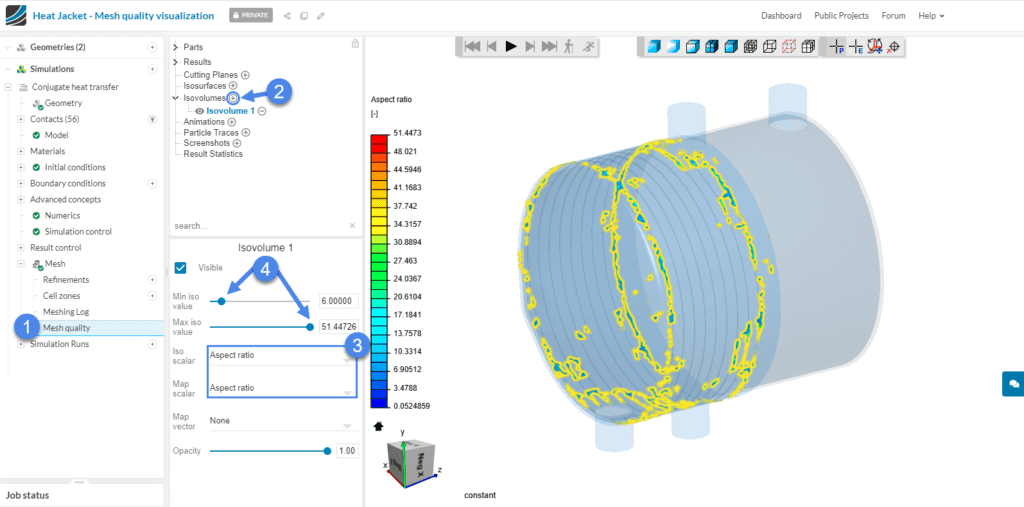

The following picture gives a preview of what the result of checking the mesh quality could look like:

The quality of a mesh can be assessed by different metrics that are usually based upon the geometrical properties of the mesh cells (e.g. Aspect ratio) or upon the relation between neighboring cells (e.g. non-orthogonality). As the suitability of a mesh for a simulation is also strongly influenced by the simulated physics, the simulation solver, and the geometrical domain, the quality metrics can only give an indication if a mesh is a good fit for a simulation setup. As an example, you can find that simple incompressible CFD simulations are usually much less sensitive towards poor quality cells than compressible flow with high-density changes.

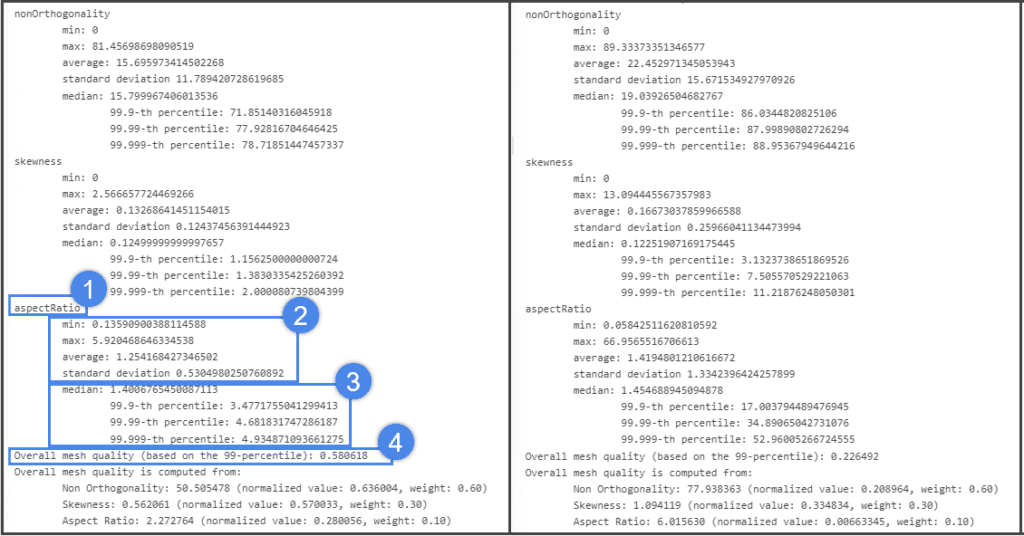

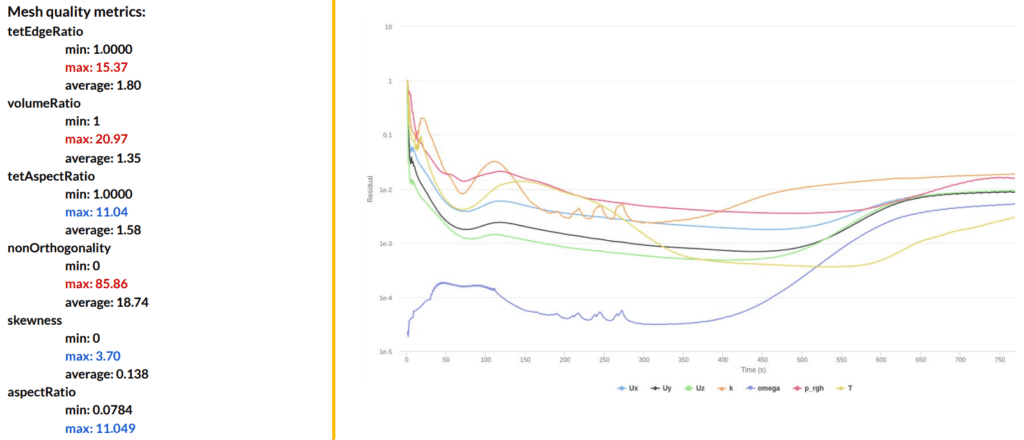

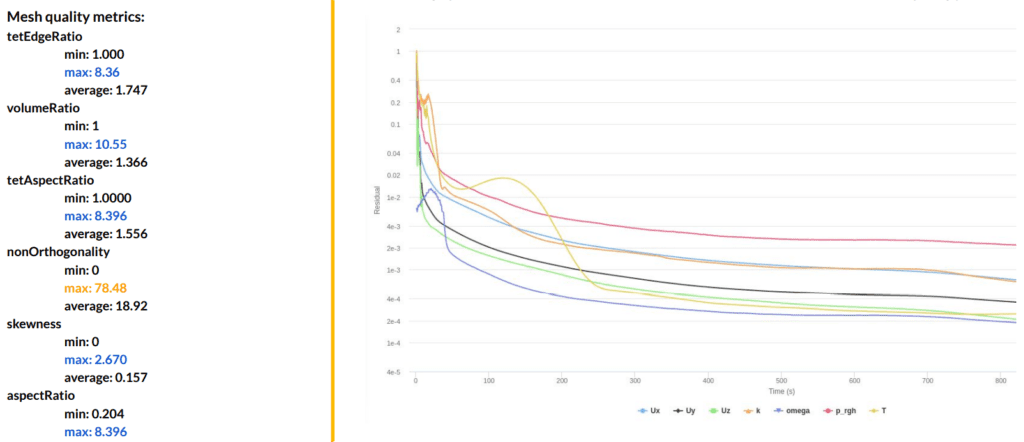

Figure 6 shows the meshing logs of a good and bad quality mesh. The marked points indicate:

The following table shows convenient ranges for some mesh quality metrics based on our best practices. The “maximum” means that the maximum quality metric that allows the simulation to run, most likely without the mesh quality-related solver divergence. The “recommended” means the maximum recommended range for ensuring a good quality mesh. CFD and FEA indicate the quality metrics for CFD and FEA solvers.

It is important to mention that the following numbers are not a must, but a recommendation. As an example, if the non-orthogonality is above 85, 80% of the time, the CFD simulations fail. This does not mean that a simulation with a mesh non-orthogonality above 86 will definitely fail or non-orthogonality above 84 will definitely succeed. However, low-quality meshes will most likely cause numerical errors and either fail the simulations or cause unreliable results.

| Mesh Quality Metric | Maximum, CFD | Recommended, CFD | Maximum, FEA | Recommended, FEA |

| aspectRatio | 20 | 10 | 80 | 4 |

| nonOrthogonality | 85 | 60 | 90 | 60 |

| tetEdgeRatio | 100 | 10 | 100 | 10 |

| volumeRatio | 80 | 10 | 100 | 30 |

| skewness | 0.85 | 0.25 | 0.85 | 0.25 |

Note

Volume ratio and non-orthogonality are defined on each face of the mesh. SimScale displays the maximum value for all faces which belong to a cell.

In the following examples, you will see the influence of low-quality mesh and high-quality mesh on simulation stability.

The picture above presents the meshing log and convergence plot of a simulation with low-quality mesh. Low-quality mesh metrics are marked with red color. The convergence plot indicates that simulation diverged approximately after 400 iterations. The results from this simulation will be unreliable. For more information about convergence, please check the How to Check Convergence of a CFD Simulation? article.

Above, you see the meshing log and convergence plot from a successful simulation. High-quality mesh metrics are marked with blue color. The residual plot shows that the simulation is stable. This example shows that improving the mesh quality metrics created a significant impact on the simulation stability.

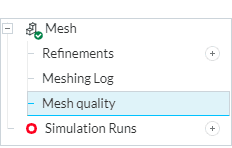

Mesh quality metrics can be accessed in the navigation tree under ‘Mesh’ after the meshing is finished.

The post-processing viewer loads the mesh and computes the mesh quality on the fly. It might, therefore, take up to a few minutes for big meshes (> 10 Million cells). You can display the different mesh quality metrics the same way result fields are displayed for simulation results.

While all display filters are available for mesh fields, the Isovolume filter is especially handy. This filter allows you to isolate bad quality cells by adjusting the minimum or maximum threshold value to the recommended limits. The following picture shows how to create an Isovolume:

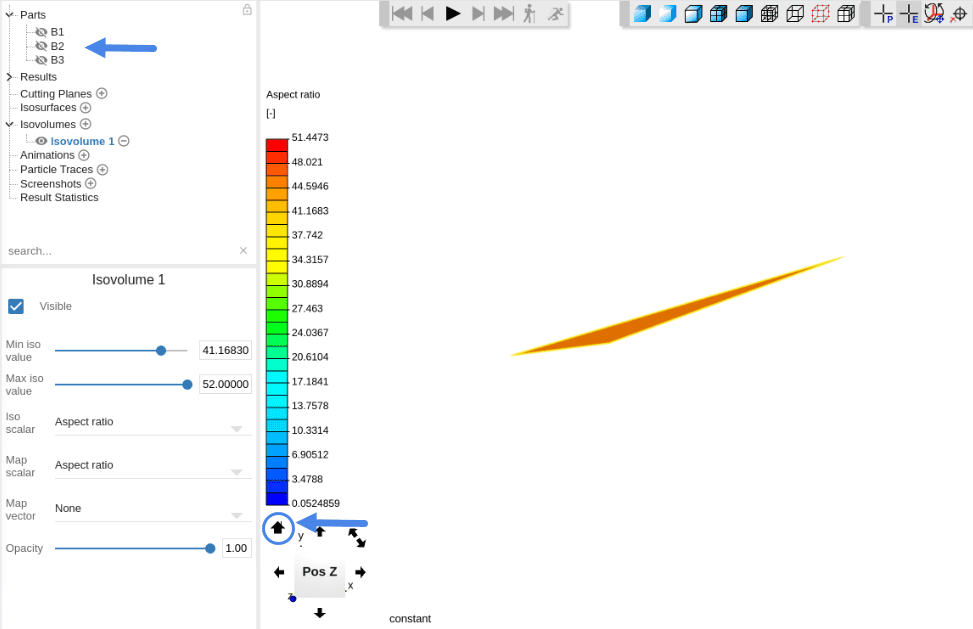

Sometimes the worst elements in the mesh will be very small, and when you try to isolate them, they will be hard or near enough impossible to spot. In such a case, it is helpful to hide the Parts completely and use the home button next to the orientation cube to zoom into the current extents of the visualization. In case there are tiny bad elements in several parts of the model, you may find yourself needing to restrict the Isovolume thresholds further. Once you have zoomed into the bad elements, you can then enable the Part visualization again to locate the cells within the model.

If you are wondering how to create good meshes, check out the meshing tutorial for the standard mesher.

Low mesh quality most likely causes numerical errors and cause divergence (simulation failure). In some cases, simulations do not fail but end up with unreliable results. Therefore, if you observe any of those problems, check the meshing log first. Compare the quality metrics with our best practices. If the metrics show that the mesh quality is insufficient, visualize the mesh, using the mesh quality tool. A complete mesh quality check and how to improve a mesh guide can be found in the How to check and improve mesh quality? article. In this article, you will find some practical measures to improve the mesh quality. This includes updating the CAD model and adjusting the mesh settings.

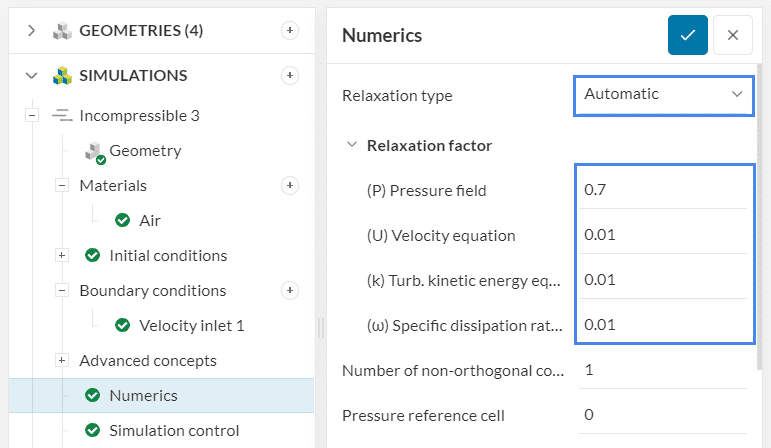

Our OpenFOAM solvers allow adjusting of the numerics. If the mesh quality is questionable, as a last resort, you may also adjust the numerics to overcome the mesh quality-related numerical errors.

You may adjust the relaxation factors to ‘Automatic’. For more information about the relaxation factors, check out the CFD Numerics: Relaxation factors page.

Non-orthogonal correctors intend to correct the fluxes in the flow direction by repeating the pressure iterations. As a result, they increase the computational requirement. The increase in the Number of non-orthogonal correctors should be with respect to the maximum non-orthogonality metric:

If the max nonOrthogonality is above 85, better improve the mesh quality. In this case, it is no longer feasible to increase the number of non-orthogonal correctors.

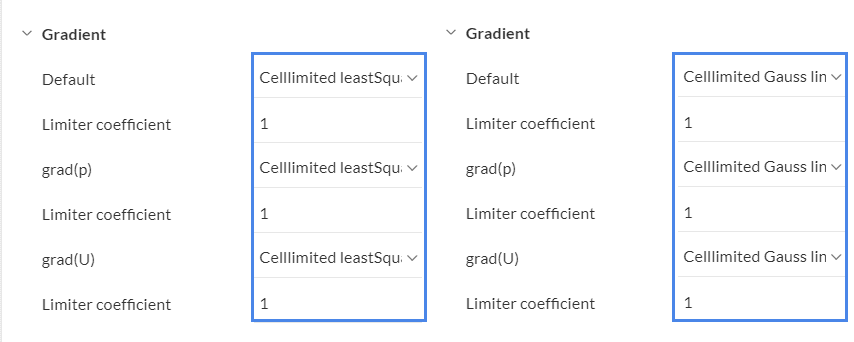

The cellLimited scheme limits the gradient such that when cell values are extrapolated to faces using the calculated gradient, the face values do not fall outside the bounds of values in surrounding cells.

A limiting coefficient is specified after the underlying scheme for which 1 guarantees boundedness and 0 applies no limiting. Practically speaking, use 0 for accuracy and 1 for improving stability.

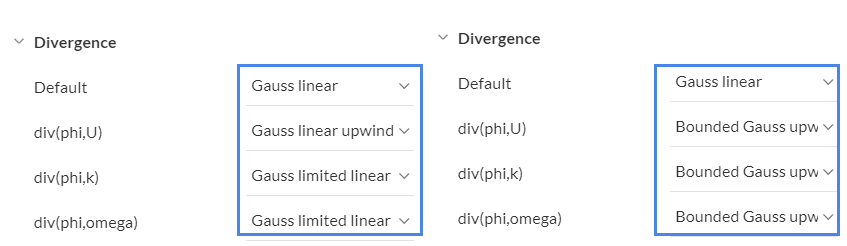

The divergence schemes are convective discretization schemes. Briefly, first-order schemes are easier to converge and second-order schemes are more accurate.

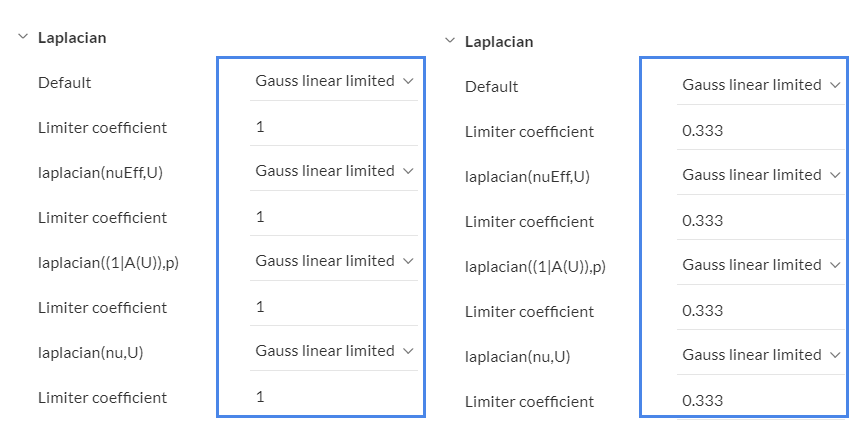

Laplacian is a differential operator given by the divergence of the gradient of a scalar function. A typical Laplacian term is the diffusion term in the momentum equations. The limiter coefficient varies between 0 and 1.

You may use the following best practices in selecting the Laplacian schemes:

Similarly to the Laplacian terms, use the following best practices for the Surface normal gradients:

Note

If you have questions or suggestions, please reach out either via the forum or contact us directly.

Last updated: September 12th, 2022

We appreciate and value your feedback.

Sign up for SimScale

and start simulating now