EPRO ENGINEERING is a new Swiss engineering company in the field of building technology, which emerged from the established companies Energieatelier AG and Eproplan AG. The team, composed of around 50 employees, is located in Berne. Together, they devise high-quality solutions with a sharp sustainability focus.

In enclosed spaces such as parking garages, the fumes from the cars entering, exiting, and driving through the facility can potentially build up to toxic levels. When coupled with an inadequate ventilation system, these gases can cause harmful side-effects, even in low quantities, to people that utilize the space. In order to mitigate these effects, companies such as EPRO ENGINEERING step in.

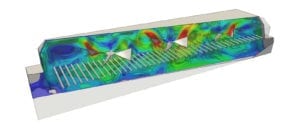

This project from EPRO ENGINEERING involved simulating a parking garage of a residential complex that had a total of 149 parking spaces. To avoid too high concentrations of pollutants (CO/NOx) which can otherwise be hazardous to humans, a parking lot must be sufficiently ventilated according to the Swiss guideline SWKI VA 103-01:2017. Using a fluid flow, or computational fluid dynamic (CFD) simulation is the only possibility to fully understand the airflow and CO distribution of the cars in the garage in order to optimize the overall design concept. Therefore, the team at EPRO ENGINEERING turned to SimScale’s online CFD platform.

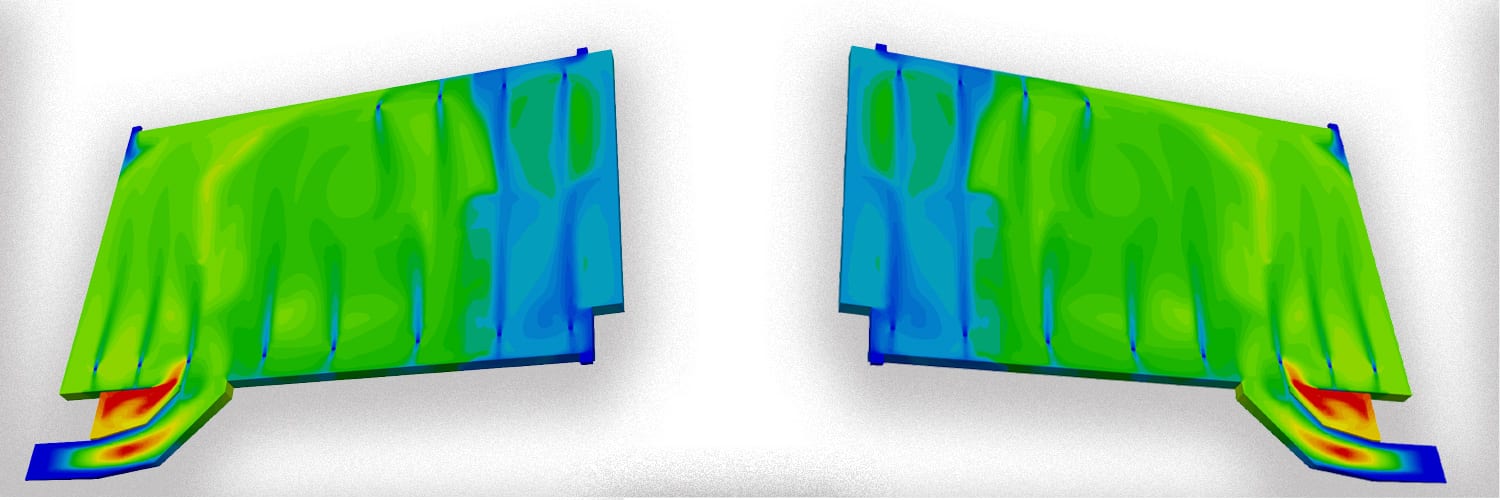

The garage was modeled using the BIM (building information modeling) software Revit and imported into SimScale with all the relevant details. The CO emissions from the cars were modelled on the lanes with cartesian boxes and equipped with a scalar transport property using the incompressible fluid flow module on SimScale. In order to test different options of the ventilation system and to select the best one, a total of ten variants were simulated. After finding the right level of detail in Revit and choosing the right mesh for the system which was a Hex-dominant mesh, the models were running smoothly and ready for evaluation.

The simulation took about 150 core hours, distributed over 16 to 32 cores, and resulted in a duration of about 5-10 hours in real-time. Mainly the flow velocity and the concentration of the scalar T1 (to represent CO) were evaluated to understand the system.

SimScale shortens the project processing time for flow simulations in architecture and building technology, enabling simulation as an integral part of the design. This allows meaningful solutions that save money, resources, energy, and space. In turn, this is how truly sustainable solutions are achieved.

Moritz Zwahlen

Team Lead of Building Climate Control & Digitalization

Using cloud-based CFD simulation with SimScale, Moritz and his team could show that the ventilation of the parking hall worked with natural air supply shafts – both with closed and open entrance gates.

This optimization reduced the investment costs of the ventilation infrastructure in the parking garage by about 40%, thus saving energy, resources, coordination effort, and space. This simplification was able to provide many advantages to all project participants.

Next Steps

The next steps in this project involve a simplified ventilation concept which will then be built accordingly. During building operation, the CO concentration will be measured and compared with the simulation results in order to achieve further planning reliability.

CFD simulations with SimScale bring the benefit of a deeper understanding of the architecture which easily enables detailed analyses and tailor-made concepts. SimScale provides the right tool to reach the goal as efficiently as possible. In the future, EPRO ENGINEERING will increasingly recommend and sell this service to their customers to increase the added value in the whole project phase.

Sign up for SimScale

and start simulating now