The miniaturization of electronics is creating new unique challenges in the thermal design of electronic components. How can you, as an engineer, ensure the thermal performance of your products and meet other design requirements? Fluid flow simulation and thermal analysis have emerged as vital tools in addressing thermal management and cooling problems, allowing engineers to accurately predict the temperature and heat flux distributions in and around an electronic system, guiding them towards smarter design decisions.

Download ‘Electronics Cooling: The Ultimate Guide’ to learn everything you need to know about modern electronics cooling.

With the aid of engineering simulation or CAE, electronics designers and engineers can:

Validate Material Decisions

Validate Material Decisions

The thermo-physical properties of the materials you choose can largely determine the thermal performance of the final design, making the material selection one of the primary design decisions. The thermal conductivity of materials such as copper or silicon can change over the expected range of operating temperatures. Thermal simulation software allows you to validate your material decisions and test their conductivity for a faster cooling process, keeping semiconductors cool enough to prevent failure.

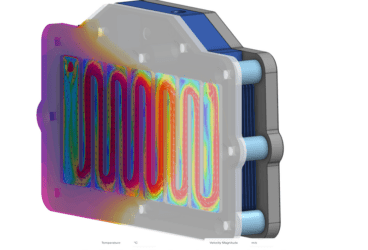

Find the Right Placement for Fans and Heat Sinks

Find the Right Placement for Fans and Heat Sinks

Fans and heat sinks are widely used in electronics for active and passive colling management, in order to keep the temperature within specified limits. It is important to optimize the flow path and ensure that the heat sinks are placed in such a way that they don’t impede it. Visualizing the airflow and temperature distribution around different components inside the electronics enclosure enables you to identify the best possible placement of fans and heat sinks for a more efficient cooling process.

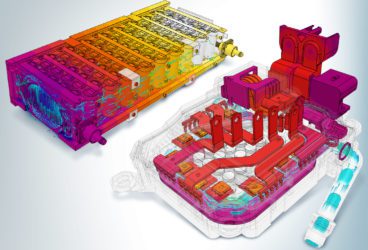

Test Enclosure Dimensions

Test Enclosure Dimensions

The physical size of the enclosure is the primary factor in determining its ability to dissipate heat, making it a fundamental factor in thermal design. Engineering simulation tools allow you to analyze the heat flow and decide on the best dimensions of an electronics enclosure and ensure the effectiveness of the cooling strategy for semiconductors.

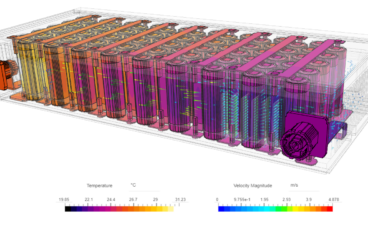

Compare Active & Passive Cooling

Compare Active & Passive Cooling

Modern thermal technologies present designers with a wide variety of strategies for electronics cooling. Should you use heat sinks or fans—or a combination of both? Would passive cooling be enough to prevent thermal damage to your product? Should you invest in an active thermal management solution despite its costs and noise concerns? Evaluate your options and choose the most appropriate cooling strategy for your product based on the simulation results.

Ensure Energy Efficiency

Ensure Energy Efficiency

The increasing energy costs and the need for reducing energy consumption are driving the demand for not only effective but also energy-efficient cooling solutions. Thermal simulation helps you virtually test different types, dimensions, and placements of heat sinks and fans to improve energy efficiency for cooling and eliminate excessive components.

If you want to learn about all of our thermal modeling software solutions, check out our thermal analysis hub.

To learn how you, as a designer or engineer, can benefit from virtual prototyping in thermal design, download this free infographic!