Technology is driving the industrial boom. Many of today’s success stories in digital transformation are Unicorns—a popular label for technology startups that reached their first $1 billion within the first three years [1]. Fortune counts more than 80 startups that have been valued at a minimum of $1 billion in the period of booming disruptive technologies period. [2]

Any successful business needs to start with a brilliant idea. In the tech industry, many leaders started in a garage with an old car, selling investment capital. A successful engineering startup entrepreneur needs management skills, winning commitment, and decision-making abilities to stand any chance in today’s competitive landscape.

Anyone who is interested in starting a new business does not concentrate on the risk of failure. According to Small Business Administration (SBA) statistics [3], half of all new companies survive at least five years and only a third survive ten years or more. Bloomberg analysis is more dramatic: 8 out of 10 entrepreneurs who start businesses fail within the first 18 months. A whopping 80% crash and burn. [4]

The Secrets of A Successful Engineering Startup

Before becoming Unicorns, startup entrepreneurs should think about and plan how they are going to survive and grow. First of all, there is a need for managerial skills, but not all good engineers are also good managers. Many of them have a vision but not the practical skills to open and manage a small business.

Startup managers often start small businesses focused on a product or service they know and has had good results, but they often lack a realistic business plan. The ability to think creatively and have enthusiasm are prerequisites, but so is a practical plan.

A business plan helps entrepreneurs understand the market, evaluate their positioning, clarify the relationships between operating expenses, prices and profits. The fact is, 80% of small businesses fail simply because owners don’t develop an effective business plan.

Things every successful startup entrepreneur should know:

- How to grow the business area of a product to become competitive

- How to develop the team’s performance based on individual experience and professional skills.

- Time is more critical in reaching profitability; use agility as one of the main advantages.

SimScale: A Computer-Aided Engineering Startup for Startups

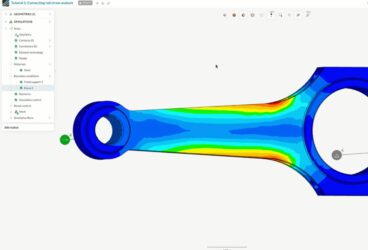

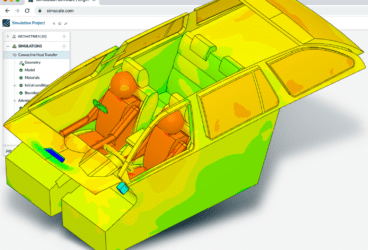

SimScale is a successful model of startup developed as consequence of digital transformation. Founded in 2012 in Munich, Germany, SimScale is comprised of a talented team of engineers, computer scientists, and mathematicians who are dedicated to making simulation technology accessible to everyone. SimScale’s vision is to remove the barriers of traditional CAE software and make engineering simulation a standard tool for every engineer and designer, regardless of their company size, know-how, or resources.

SimScale is a successful model of startup developed as consequence of digital transformation. Founded in 2012 in Munich, Germany, SimScale is comprised of a talented team of engineers, computer scientists, and mathematicians who are dedicated to making simulation technology accessible to everyone. SimScale’s vision is to remove the barriers of traditional CAE software and make engineering simulation a standard tool for every engineer and designer, regardless of their company size, know-how, or resources.

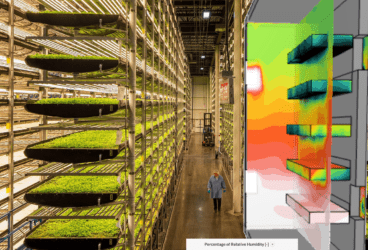

Startups now have the ability to use 3D simulation to bring their designs to reality much more quickly than ever before. Using SimScale, they can develop their products better, faster and cheaper than with traditional, license-based CAE software.

10 Reasons Why Startups Should Simulate with SimScale

1. Cost-effective subscription plan – most common startup failures have financial roots. Investing in perpetual CAE software licenses without profit warranty can be prohibitive. As an alternative to six-figure prices per seat with traditional CAE software, SimScale provides a cost-effective pricing, with zero investment in special hardware necessary.

2. Forget the supplementary investments – usually, an engineering consulting firm that provides creative engineering services like research, feasibility studies, concept generation or prototyping simulations should invest in supplementary computing resources for projects requiring powerful graphic stations, high-quality monitors, supplementary storage resources and big networking bandwidth. With the SimScale platform provided as SaaS, subscribers don’t need any additional hardware or software resources. They only need a web browser, a standard laptop or PC, and a stable Internet connection.

3. CapEx relaxation – a common mistake for many small businesses is having insufficient operating funds. Startup managers underestimate how much money is needed in different development stages due to an unrealistic expectation of incoming revenues. With the SaaS model offered by SimScale, any subscription plan could be related to operational expenses because it is easier to manage and to change according to the business development needs. Flexibility saves users money.

4. No hidden costs – often, users of on-premises CAD and CAE software complain about an unreasonable subscription policy. Some providers run sales campaigns offering free upgrades to the next level software version. The problems start when clients have to pay a more expensive maintenance subscription. A client with a five or six-year-old version who wants to upgrade has to pay 25-30% more for a new license. With SimScale’s subscription model, startups could make easier OPEX plans, they could start with simulation for free and scale the capacity as needed. There are no other fixed expenses, no maintenance fees, and no long-term commitment.

5. Easy to use and learn – engineering software is not used for simple applications. Complexity and the specialization level make simulation a technology that is difficult to learn and use, even for product design specialists. Training requires more money, time and resources. SimScale offers easy access via a web browser, user-friendly interface, and a lot of training facilities for less experienced users: e-mail and online assistance, tutorials and documentation, workshops and webinars, forum and professional training services.

6. Fast products on the market – traditional engineering workflows depend on the setup processes assigned to each product development and manufacturing phase. Looking only to prototypes testing, redesigning and retesting activities, there are operations that require a lot of time and supplementary costs. Virtual prototyping and interactive collaboration between CAD and CAE teams based on the same digital model contribute to a dramatic reduction in process time and the costs associated with physical prototyping and testing.

7. Processes simplification – delivering projects more quickly to clients is an added advantage that allows design engineers the opportunity to increase their revenue from additional new business projects. More products or a larger product variety opens doors for large markets and more potential clients. This could be a very competitive advantage for a startup entering the global market—compared to old traditional companies that didn’t adopt innovation so fast or didn’t have a technology adoption strategy.

8. Freedom to work anywhere – copyright licensing limitation and user permission associated with a specific computer are the current issues for on-premises software. Often clients have to change or to reconfigure their computers and lose their installation permission due to licensing limitations. SimScale accounts are associated with individual users and are not tied to specific computers. Users can run CFD or FEA simulations anytime, on any desktop computer or laptop. There are no problems with licensing.

9. Real-time collaboration – many products and process failures are related to a weakness in project management. Industry literature is full of worst-practice stories related to lack of collaboration between different engineering and design teams. The bridge with half parts never to meet, balcony for non-existent windows, or different level tunnels are very popular. But any mistake or malfunction is generating losses. Often, this is an expensive and unpredictable loss. Working in the cloud on the same digital model, engineering teams can collaborate and work simultaneously on the same CAE project. Moreover, designers and engineers can instantly see other contributor’s changes in real-time. No more wasted time with delays or security risks generated by sharing files by email or Dropbox.

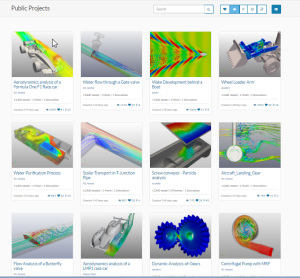

10. Open and collaborative know-how sharing – many classic CAE solutions are very hard to use and learn due to incoherent training programs provided by the vendors or the channel partners. On the other hand, very high costs associated with simulation software and computing power restrict access to professional training, which is often limited to a small number of specialists. By making engineering simulation methods accessible to everyone, SimScale enables the international know-how transfer between engineers and designers through the SimScale Public Projects Library. It’s a win-win knowledge strategy. Here, experienced engineers can have free access to simulation software and less experienced users can learn from more thousands of public simulation set ups in the Projects Library, using them as templates for their own engineering development projects.

Many startups are already working with the SimScale simulation software platform. SimScale now has more than 65,000 users that are simulating online. Join them!

Create your free community account with SimScale, no payment data is required.

References

- Aileen Lee, “Welcome To the Unicorn Club: Learning From Billion-Dollar Startups”, TechCrunch, 2013

- Erin Griffith, Dan Primack, „The Age of Unicorns”, Fortune.com, 2015

- Patricia Schaefer, “The Seven Pitfalls of Business Failure and How to Avoid Them”, Business Know-How

- Eric Wagner, “Five Reasons 8 Out Of 10 Businesses Fail”, Forbes, 2013