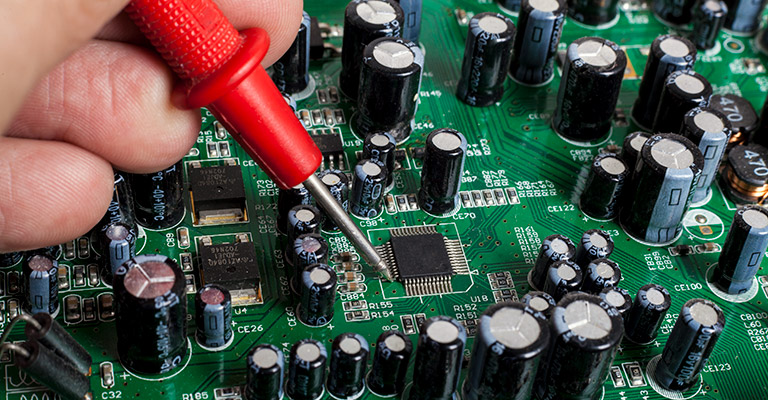

Many of the technological innovations on the market today can credit their success to the particular lighting, battery, and enclosure cooling strategy that was tried, tested, and ultimately employed early in the design process. Modern-day tech devices are becoming smaller and smaller. Therefore, their dependency on dissipating large amounts of heat from their increasingly compact internal systems is growing.

These products, including electronic devices, data centers, avionics, and even hybrid vehicle designs, to name a few, all encounter ‘high-flux’ heat dissipation, which can have disastrous results if the employed thermal management strategy is not thoroughly vetted. In order to prevent this, designs require rigorous evaluation over an iterative design process before moving on to the next stage of the production cycle.

Yet, as the marketplace becomes more and more saturated with competing products, companies, and innovations, engineers may struggle to keep pace if design testing is limited to later stages, often due to desktop-based simulation limitations when it comes to thermal management.

Luckily, SimScale’s cloud-based simulation platform is available to help engineers who need to speed up their design process, need to meet strict deadlines or who are looking to benefit from the advantages of having a non-premise-based and collaborative online simulation tool.

In this article, we will explore three electronics cooling cases, including battery cooling, lighting cooling, and enclosure cooling, and show how SimScale can help engineers working on thermal management applications be more effective and efficient.

Learn how iGas Technologies shortened their cooling system design time with SimScale; Thermal management in 5 minutes or less.

Thermal Management: Battery Cooling

One prime example where battery thermal management is needed is electric vehicles, from scooters to cars, as they require big batteries in order to operate and store energy. The energy source going into the battery pack as it is charged is measured by two variables; electrical current and voltage. The distinct flow path of the current causes heating in the battery cells, where the higher the current, the more the heating effect will be; meaning more potential for component overheating, and more need for thermal management.

In a recent post from Hunt et al from Imperial University it was found that not only the temperature but also the cooling method is critical to preserve the performance of the cells over their lifetime. Historically, the largest battery packs did not really need any specialized cooling strategy, as the physical size of the packs were sufficient in displacing the heat on their own in comparison to the flow of the current. Today, faster and faster battery charging rates are demanded, as the surge of electric vehicles continues to take to the streets across the globe, with parameters such as a recharge power of over 200kW to deliver times of 30 minutes or less.

While this example only speaks to the electric vehicle market, battery cooling is an essential strategy for electronics as a whole. Higher performance, consistency, and adequate durability in global markets has meant that specialized thermal management strategies for battery packs are the new normal. So how can you evaluate your cooling method quickly and efficiently? We are glad you asked.

Bold Battery Thermal Validation Through Cloud-Based Simulation

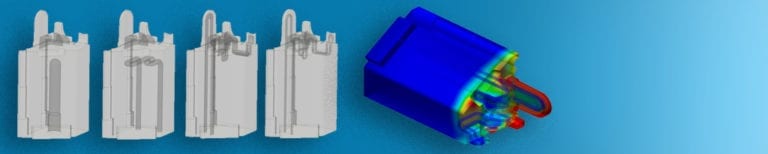

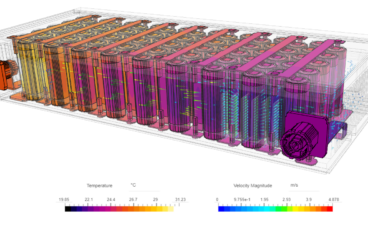

At SimScale, Bold Valuable Technology recently embarked on a new project that focused on creating a new battery design for an electric motorsport series. Integrating an effective and functional cooling system was an innately important part of the task.

“The difficulties in accurately predicting the thermal behavior and pumping losses in the cooling system were only possible to tackle using CFD tools. The main advantage we find in simulation is the speed at which we can try different ideas and design parameters. The post-processing tools allow us to understand the behavior of the system so our engineers can come up with improvements or discover issues before building prototypes.” Bernat Carreras, Director at Bold Valuable Technology

After obtaining desired results and a successful simulation experience, Bold Valuable Technology plans to expand on their use of online simulation with more detailed models to better predict the thermal behavior of their cooling systems. Read more about their battery cooling evaluation experience here.

However, it’s not only electronics cooling experts that can benefit from SimScale. Beginners can start simulating their electronics cooling designs even without a finalized design by simply copying one of our existing thermal management projects, like the one below.

How to Get Started With Thermal Management Using SimScale

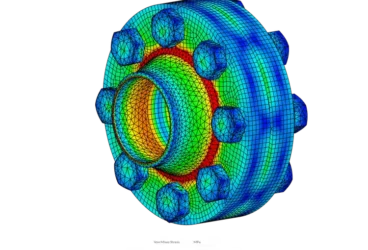

This public project demonstrates how engineers can take their CAD model (in this case, a powertrain or internal combustion engine cooling system), set up a simulation, and get fast results to facilitate an iterative design process.

Thermal Management: LED Lighting Design Considerations

For engineers, lighting doesn’t just happen with the flick of a switch. In addition to understanding how to cool the internal components within a lighting system, you first need a basic understanding of how a lighting system works and affects a building’s overall energy use, its impact on the overall cooling and heating loads, and how and when to consider alternative solutions.

Employing the right electronics cooling strategy for a lighting solution is essential. A few years ago, the U.S. EPA Energy Star Building Upgrade Manual stated that lighting was typically the largest source of waste heat, consuming around 35% of the net electricity for commercial buildings.

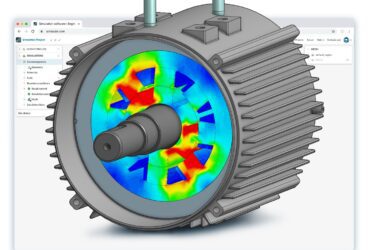

Engineers must select, design, and iteratively redesign lighting systems, so that they not only complement the intended use case or HVAC system, but also manage thermal conditions. Yet, LED optical performance and lifespan can both decrease drastically with rising temperatures. LED lighting cooling is a perfect use case where CFD can be used for optimizing a lighting system design to predict LED chip temperatures and ensure high optical performance and product longevity.

Lighting System Cooling Project: LED Spotlight

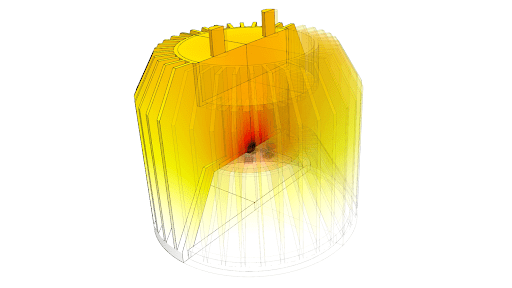

In this recent article, we dive into an LED spotlight electronics cooling project, where conjugate heat transfer (CHT) is used within SimScale to evaluate the design, focusing on heat sink optimization. The piece addresses the main issues arising from thermal management, different types of electronic cooling solutions, and gives recent examples of how these have been wrongly utilized by companies.

In this thermal management public project that can be copied and used by any SimScale user, we walk you through how to set up this type of simulation, including material assignments and boundary conditions, and provide results confirming numerical convergence and showing through post-processing visualizations how and where the heat is transferred from the heating element to the rest of the geometry.

The thermal management results, obtained in a matter of hours from SimScale’s cloud-based platform, also indicate how the design could be improved upon for further iterations. To read the whole article, find it here.

QRC Technologies prevented thermal damage in its electronics design with SimScale. Over 5 iterations tested, 6 weeks saved, and $40K average savings on hardware.

Thermal Management: Enclosure Cooling

Electronic enclosure cooling systems are employed to effectively dissipate heat from sealed electrical and electronic enclosures operating in indoor, outdoor, and other types of environments. These systems are used for applications ranging across a vast array of industries, including but not limited to industrial automation, chemical, wastewater treatment, telecommunications, petrochemical, and so on. We will provide two thermal management examples of how enclosure cooling strategies can be evaluated within SimScale.

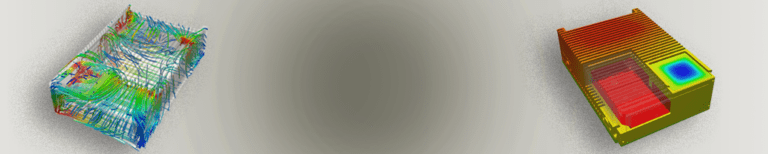

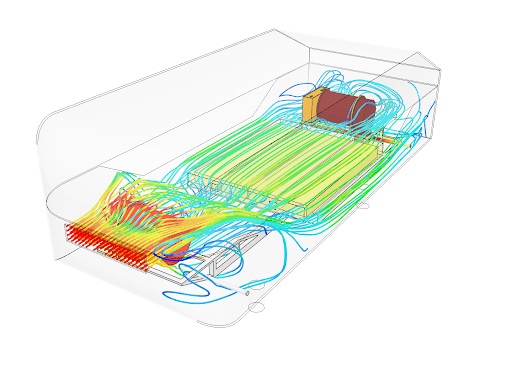

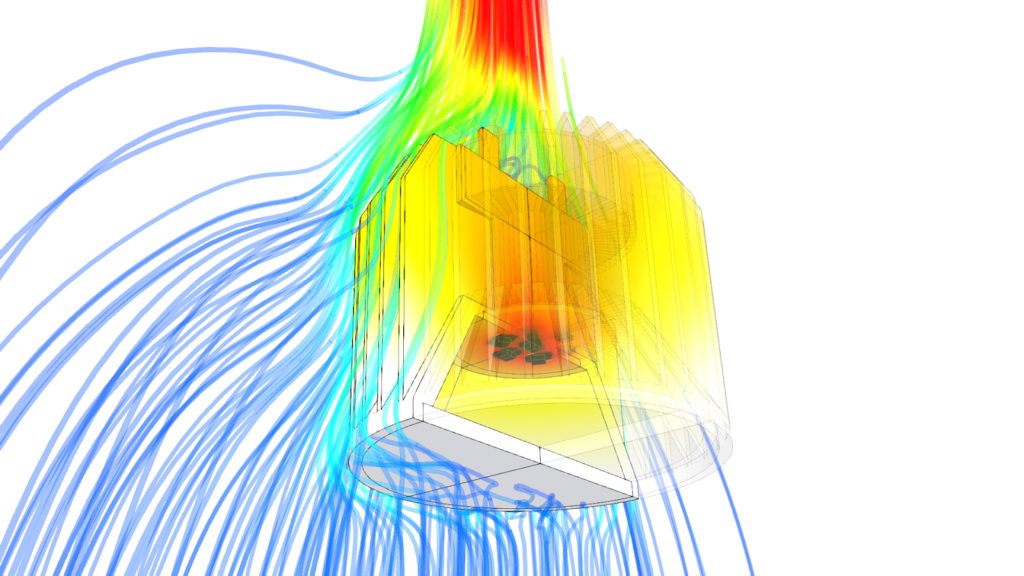

This thermal analysis of a graphics processing unit (GPU) enclosure shows how an industrial application can be tested. The simulation results help one to visualize how heat is distributed within a GPU on the edge, cooled via an active fan from the top of the enclosure.

How to Get Started With Enclosure Cooling Using SimScale

In this programmable heating mantle public project, The CAD model (created in OnShape) consists of components including casing, structural, and electronics parts. The enclosure cooling challenge comes as the initial design goal (heating up containers) must also comply with working conditions of mechanical stress, safety, ergonomy, and thermal load in order to make sure the final product will work effectively. Once the CAD is developed in OnShape, we will then assess the thermal management through thermodynamic simulation using SimScale. Read all about this case study here.

Learn how PRISMADD Japan uses SimScale to optimize their water cooling systems for high-temperature aluminum casting.

Want to Learn More About Enclosure Cooling Possibilities Within SimScale?

- LED Cooling: Liquid Cooling Thermal Management

- Electronics Enclosure Design for Better Heat Dissipation

- 5 Ready-To-Use Electronics Cooling Simulation Templates