Documentation

Before initiating a simulation task, it is important to prepare for the task in order to achieve the desired result. Every CAE simulation requires some preparation to be done before it can be numerically set up and performed. This step is called Pre-processing.

Pre-processing is the stage that precedes the simulation process. It involves all the steps you need to take in order to prepare your geometry for simulation analysis.

In pre-processing, you will, amongst other things:

For the simulation setup to be accurate, you need to know what the physics involved in the problem statement is and what is to be solved. If this is unclear, then even though the setup is verified for mathematical errors, it may still not be physically valid. In other words, the equations being used, even though solved correctly, will not be applicable to the problem statement.

For the uploaded CAD geometry to be valid, it is necessary to be checked for any errors, such as intersecting faces or open edges. This is done by cleaning the geometry and making it mesh-friendly.

Some problems can be solved in two dimensions, while others need a three-dimensional full-fledged geometry. In CFD and FEA simulations, one choice leads to another. Depending on the complexity of the geometry and the setup involved, time and money can be saved through reduced computational needs.

A mesh is a discretization of the domain to be simulated into tiny cells or segments. This discretization will most likely fail if the geometry is invalid. To solve a set of differential equations numerically, we have to discretise the computational domain, i.e. represent them as a finite set of values at specific points in space.

The mesh has both numerical and physical effects on the solution. Numerically, the mesh quality affects the accuracy of the solution of the equations. Most obviously, using a larger amount of smaller cells gives a finer resolution of the solution while also taking a relatively long time to solve.

For Finite Element Analysis (FEA), you will usually create a mesh of the actual model, while in Computational Fluid Dynamics (CFD), you will most likely create a mesh around the actual model. In CFD, the mesh would be of different types, such as cartesian, curvilinear, or unstructured.

Mastering the art of pre-processing is the first step towards becoming a simulation expert. We at SimScale strive to make this step easy for you with the following resources:

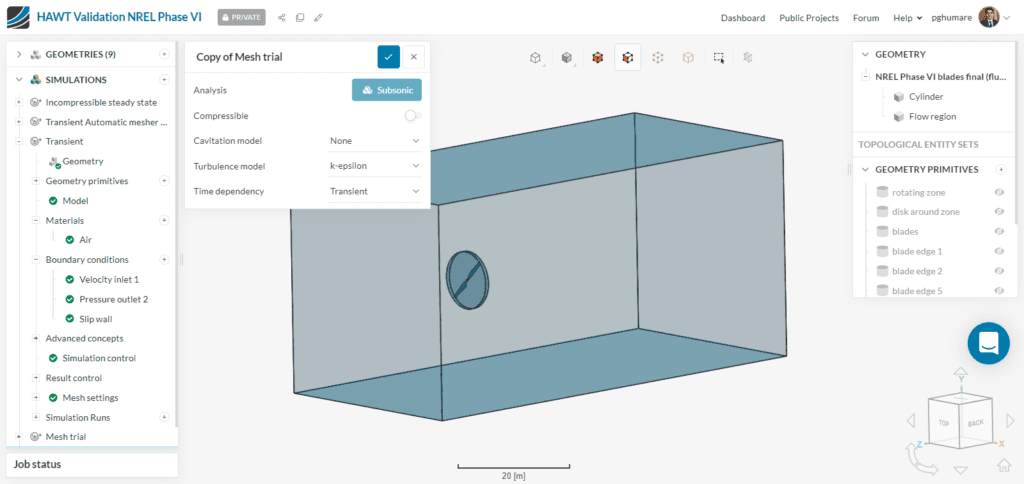

Within the SimScale software environment, pre-processing happens in the following three main stages:

Explore SimScale’s world of simulation in your browser and work your way through pre-processing steps before conducting your simulation by signing up here.

Last updated: August 24th, 2023

We appreciate and value your feedback.

What's Next

CAD TopologySign up for SimScale

and start simulating now