Documentation

Rotating zones can be used to model rotating systems such as turbines, fans, ventilators, and other similar systems. This documentation page shows how simulation with rotating zones can be set up.

Note

Rotating zones are only available for the following analysis types:

– Incompressible

– Compressible

– Convective heat transfer

– Multiphase, only if Local time stepping is disabled in the global settings

– Subsonic

Simulations with rotating zones require special attention during CAD preparation. The requirements are described at length in the following knowledge base article:

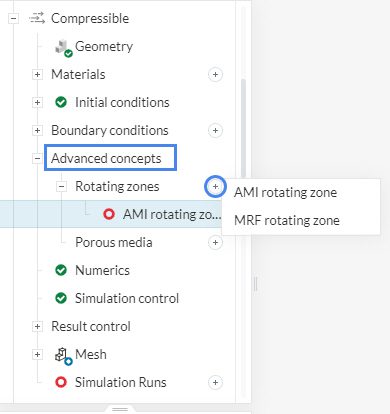

In the simulation tree, navigate to Advanced concepts and click on the ‘+’ button next to Rotating zones. Two types of rotating zones are supported: Multiple Reference Frame (MRF) and Arbitrary Mesh Interface (AMI).

The MRF rotating zone is a steady-state approximation of the transient rotating motion at an “instance” of time. Therefore, the mesh/body is not physically rotated. One must make sure that the problem does not include large-scale transient phenomena.

This approach uses a rotating frame of reference that modifies the governing equations in the rotating zone. Additional source terms that incorporate forces in the rotating reference frame are taken into account. These simulate a rotation effect in the flow.

Performing MRF simulations is computationally much less demanding than transient modeling. Hence, if the problem is set up correctly, MRF provides good approximations with less computational effort and considerably less computation time.

Setup of an MRF Rotating Zone

Figure 3 shows the setup interface for a MRF rotating zone:

Did you know?

In the right-hand rule, the rotation axis is represented by the right-hand thumb. The motion of the other four fingers indicates the direction of the rotation.

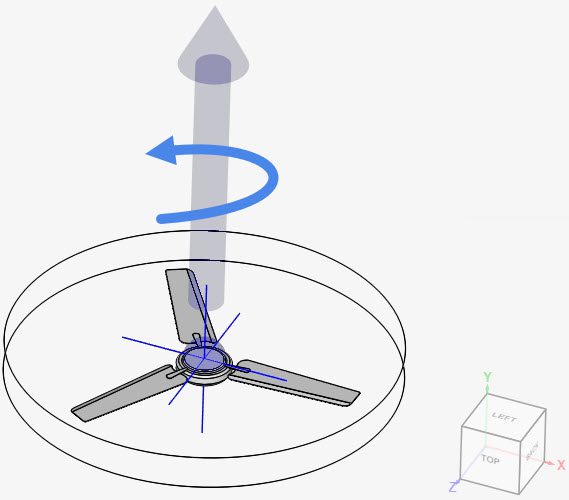

In the figure above, the rotation axis was defined in the positive y-direction. The blue arrow indicates the resulting direction of the fan rotation.

AMI rotating zone simulations are fully transient and, therefore, are computationally much more expensive than MRF. They take all transient effects into account and are usually sensitive to the time step length.

In the AMI approach, a mesh interface is created between the moving and stationary parts of the mesh. At each time step, the rotating zone is physically rotated, and quantities are interpolated at this interface to allow realistic movement of the rotating parts.

Note

In cases where large-scale transient phenomena are not observed within the rotating zone, it’s still possible to use the MRF approach, even for transient simulations.

Setup of an AMI Rotating Zone

Figure 5 shows the setup window for an AMI rotating zone:

In the mesh set up, the rotating zone volume needs to be defined as a Cell zone. The workflows to define cell zones are different, depending on the meshing algorithm. Find below the steps for each of the cases.

When using the standard mesher with physics-based meshing enabled, the algorithm automatically creates cell zones for the regions selected for any of the entries in Advanced concepts.

When Physics-based meshing is disabled, the user needs to manually define the cell zones, as in Figure 7:

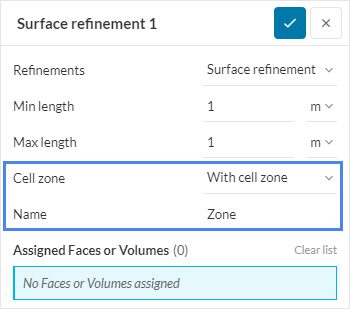

For hex-dominant meshes, the creation of a cell zone is done by adding surface refinements. When adding additional refinements in a hex mesher choose the surface refinement option.

In the settings panel, make sure Cell zone is set to ‘With cell zone’ and give a name accordingly to distinguish between multiple cell zones.

For a cell zone to be created, a closed volume (or all faces of the closed volume) needs to be assigned to the surface refinement. If successful, all cells enclosed by the assigned volume will be grouped together.

Learn more about surface refinements in our hex-dominant mesh document:

For a practical guide on how to set up and use rotating zones, take a look at the following tutorials:

Last updated: June 15th, 2023

We appreciate and value your feedback.

Sign up for SimScale

and start simulating now