SimScale is committed to making engineering simulation more accessible to all engineers, especially those working in industries that have not traditionally leveraged simulation in their design processes. This is why we are bringing a new solution to the rotating equipment market.

Digital prototyping, in many stages along the R&D cycle, not only reduces cost and time by avoiding the trial-and-error characteristics typically seen in physical prototyping but also allows engineers to explore the full design space.

We have created the world’s first cloud-native platform for engineering simulation covering fluid, thermal, structural applications, and more. Here, we cover how our simulation solution, now with additional specialization for rotating machinery, can yield reliable, accurate results faster than ever.

Versatile and Accessible

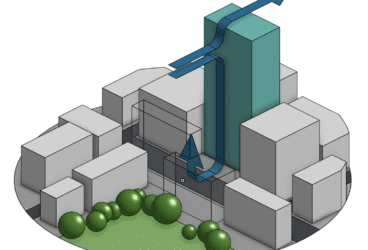

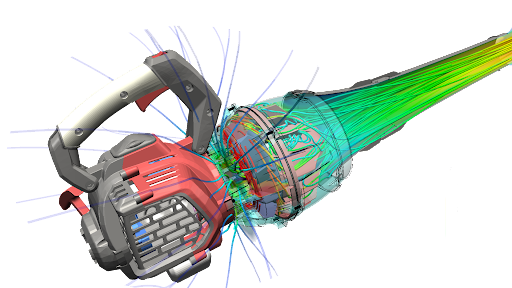

Our proprietary solver is a versatile solution for a broad range of applications within the rotating machinery industry. From compressors and fans to turbochargers and propellers, engineers can leverage engineering simulation that gets them results quickly for analyzing and improving designs.

Test this project yourself here. Run time: 4 Minutes

Accessibility is the foundation of SimScale’s vision. You can import your native CAD files, run simulations and process your results without ever leaving your web browser. As a simulation solution born in the cloud, SimScale gives engineers access to their projects from anywhere at any time. Nothing is run locally, liberating engineers from the myriad constraints of traditional simulation software. Large file sharing is a thing of the past, as projects can be shared with colleagues and customers with a simple web link.

Additionally, with SimScale’s API, you can easily integrate customized workflows with your existing tools and processes. SimScale is part of the strong push for digital transformation in the rotating equipment industry.

Fast and Accurate

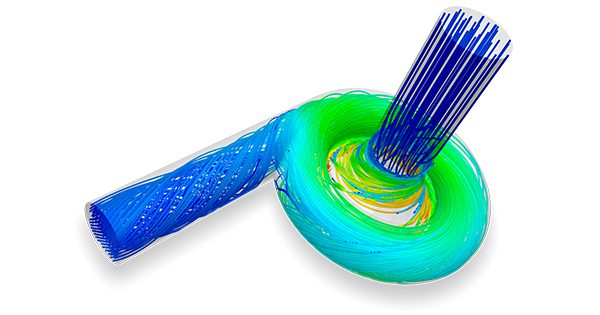

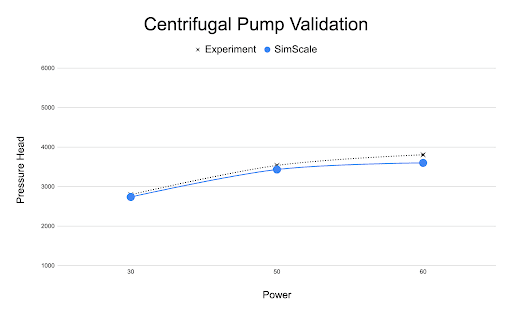

Accuracy is of utmost importance to those in the rotating equipment and industrial equipment market and, that is why we make no compromises when it comes to performing true and accurate simulation. Our proprietary solver technology, designed specifically for rotating machinery, was tested extensively, validated against industry-standard models, and approved by our very own customers. The graph below shows the strong performance, validated for both compressible and incompressible flows.

With the cloud doing the heavy lifting, SimScale’s new offering is one of the fastest solutions on the market. Meshing is completely automated and solving complex equations needed for rotating equipment simulations are handled by the cloud, leaving designers free to kick off multiple simulations in parallel and iterate with speed. Pump curves have been simulated in less than 15 minutes and were validated to within 2% of manufacturers’ data.

Learn more in our whitepaper: Simulating Turbomachinery Designs 10x Faster

New Solution for Rotating Equipment Industry

SimScale is dedicated to making simulation both technically and economically accessible. It’s why we created the world’s first platform for engineering simulation born entirely in the cloud. The power of the cloud grants engineers access to HPC, without ever leaving their web browser, facilitating accurate simulation, computational resources that scale up on-demand, exceptional ease of use, and a new suite of sharing and collaboration features. The rotating machinery industry has a strong need for accuracy and reduced turnaround times, thus demanding the adoption of scalable HPC.